Wheel setting for deep digging, Note, Cultivating – MTD 215-386-000 User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

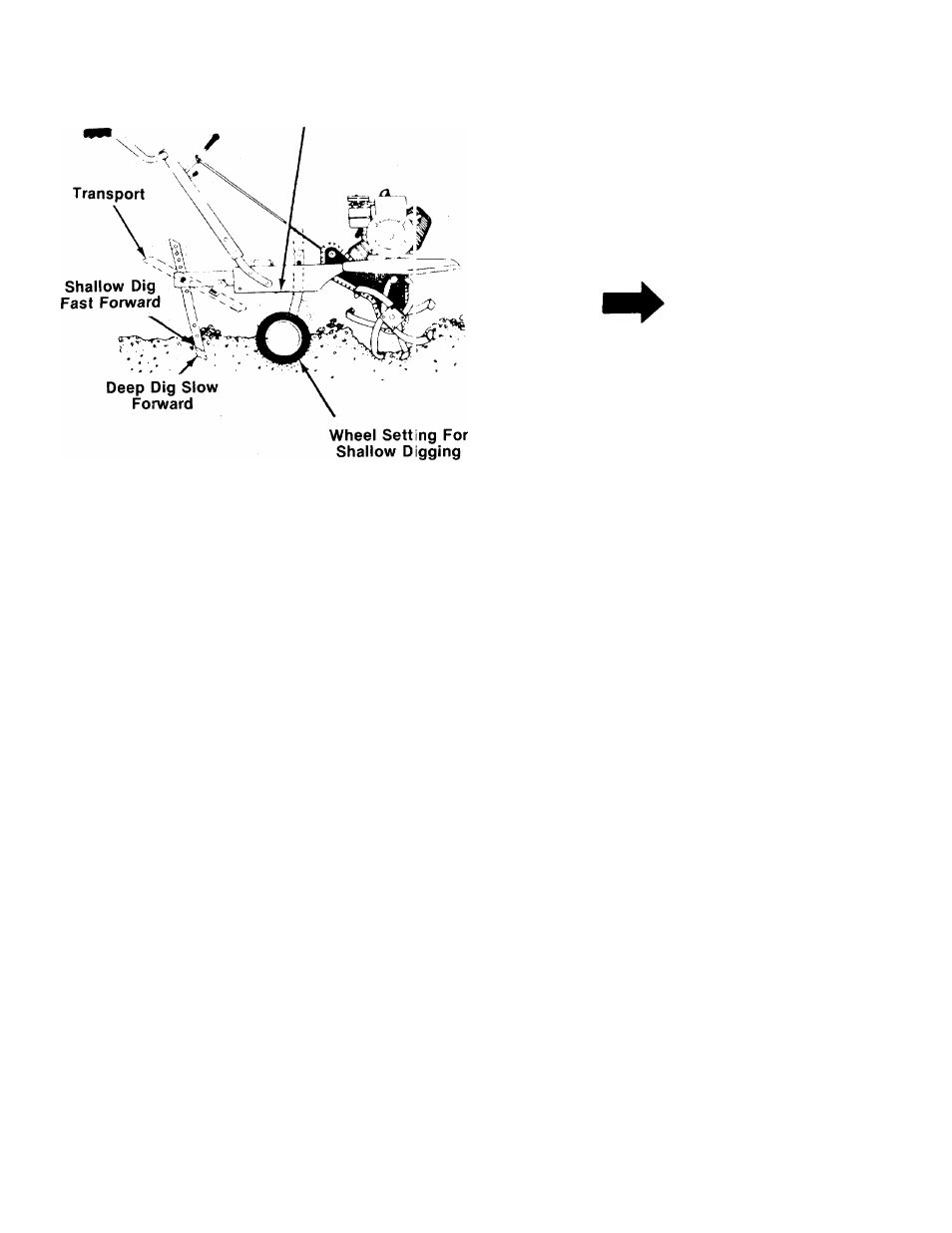

Wheel Setting

For Deep Digging

and/or Traisport

FIGURE 17.

By increasing the depth of the depth b ir, the

forward speed of the machine is reduced, and

the working depth is increased. When the

depth bar is raised, the working depth of the

machine is reduced and the forward speed is

increased. The working depth of the machine

may be predetermined by setting the depth

bar and wheels so that the wheels are about

four inches from the ground when the tines

and depth bar are resting on the ground. This

setting will permit a working depth of about

four inches. Use maximum engine speed for

deep tilling. When presetting the wirking

depth, the handles should be a little above

waist height because the tiller will be lower

when the tines and depth bar penetrate the

ground. The best method will be deternined

by the soil condition. In some soil:;, the

desired depth is obtained the first t i m j over

the garden. In other soils, the desired dc pth is

obtained by going over the garden two or

three times. In the latter case, the depth bar

should be lowered before each succeeding

pass over the garden. Passes should be made

across the length and width of the garden

alternately. Rocks which are turned up i hould

be removed from the garden area.

3.

Handle Pressure:

Further control of tilling

depth and travel speed can be obtair ed by

variation of pressure on the handles. A down

ward pressure on the handles will reduce the

working depth and increase the forward

speed. An upward pressure on the handles

will increase the working depth and reduce

the forward speed. The type of soil and work

ing conditions will determine the actual set

ting of the depth bar and the handle pressure

required.

4.

Throttle Control:

The throttle control lever is

iocated on the right side of handle panel.

NOTE

Right hand side is determined from

the

operator’s

position

standing

behind the tiller.

The throttle control lever adjusts the engine

speed. It also gives finger tip control of the car

buretor and magneto stop switch. With the throt

tle control knob pushed completely forward, the

carburetor is in “START” position. Pulling the

throttle control back slightly adjusts the engine

speed to “FAST.” Pulling the throttle back further

reduces the engine speed to “SLOW.” When the

throttle is pulled completely back, the magneto

stop switch grounds out the spark and stops the

engine. Use maximum engine speed for deep till

ing.

Move the throttle control to slow when transpor

ting the tiller. When the tiller is being moved to or

from the garden, the depth bar should be pivoted

forward until it engages the depth bar spring pin.

The machine may be moved under its own power,

without damaging grass areas as long as it is

allowed to move freely. If the operator holds back,

it will start to dig.

CULTIVATING

For cultivating, a two to three inch depth is

desirable. Setting the wheels and depth bar so

that the wheels are about two inches above the

ground while the tiller is resting on the tines and

depth bar will allow the machine to work at

cultivating depth. The throttle should be set to

control forward movement to a slow walking

speed. With standard tines, the maximum working

width of the tiller is 26 inches. This width may be

reduced to 24 inches by moving the clevis pins

and hairpin cotters to the inner holes on the tine

shaft. For cultivation, remove the outer tines to

obtain a tilling width of 13 inches.

When laying out plant rows, be sure to allow

enough width to permit cuitivation between the

rows. In growing corn or similar crops, check-row

planting will permit cross cultivation and prac

tically eliminate hand hoeing.

10