Assembly instructions, Unpacking, Installation of wheels – MTD 241-521-000 User Manual

Page 5: Parts in carton (see figure 1), Tools required for assembly, Other materials required for assembly, Valve stem facing outward

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

ASSEMBLY INSTRUCTIONS

S

IMPORTANT: This unit has been shipped without

gasoiine or oil in the engine. After assembly, refer

to separate engine manual for proper fuel and

engine oil information.

Reservoir

•s

UNPACKING

Remove

the

log

splitter

parts

from

the

carton

by

cut

ting

the

corners

of

the

carton.

Make

certain

all

parts

and

literature

have

been

removed

from

the

carton

before the carton is discarded.

All

hardware

for

assembly

of

the

log

splitter

has

been

placed in position on the various parts.

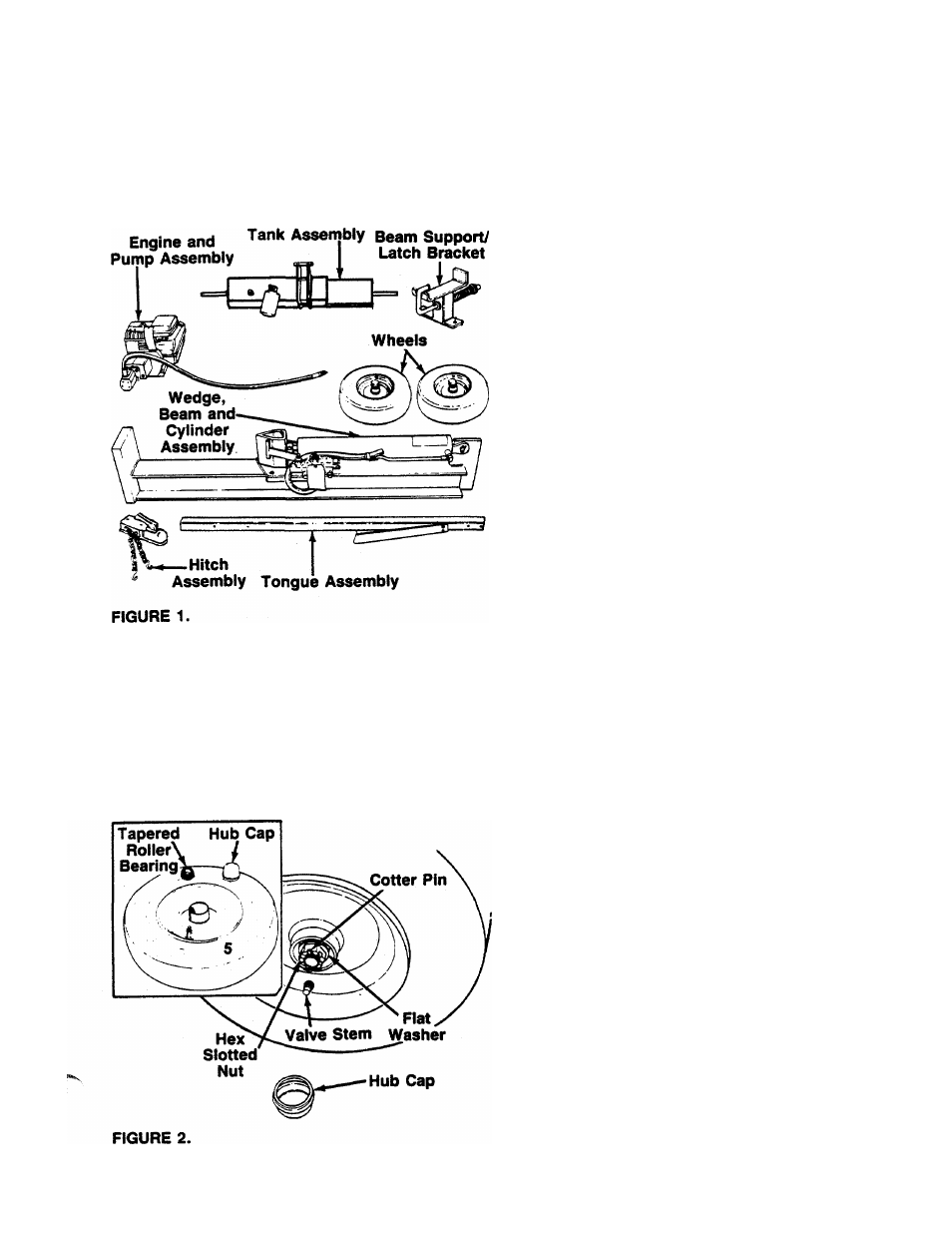

■Parts in Carton (See figure 1)

Reservoir Tank Assembly

Engine and Pump Assembly (Bolted to bottom of

carton)

Tongue Assembly

Wedge, Beam and Cylinder Assembly

Hitch Assembly

Wheels

Tools Required for Assembly

(1)

Rubber Mallet or Plastic Hammer

(2)

9/16" Wrenches*

(2) 1/2" Wrenches*

(1) Adjustable Wrench

(1) Screwdriver

*Ad]ustable Wrenches may be used.

Other Materials Required for Assembly:

Engine Oil

Unleaded Gasoline (regular grade gasoiine is an

acceptable substitute)

Approximately 4 Gallons of Dexron II Automatic

Transmission Fluid or 10W Non-Foaming Hydraulic

Fluid

INSTALLATION OF WHEELS

Attach

the

wheels

to

the

reservoir

tank

assembly

as

follows. See figure 2.

1.

2

.

3.

4.

■5.

6

.

7.

Pry off the hub caps and dust covers which are at

tached

to

the

wheels.

Discard

the

dust

covers

(us

ed for shipping only).

Remove

one

tapered

roller

bearing

from

inside

each wheel. See inset.

Remove

the

cotter

pin,

hex

slotted

nut

and

flat

washer

from

each

axle.

Place

one

wheel

on

each

axle, with the

valve stem facing outward.

Pack

the

tapered

roller

bearings

with

wheel

bear

ing grease, and place one on each axle.

Place

one

flat

washer

removed

in

step

2

on

each

axle.

Secure

with

hex

slotted

nut.

Tighten

sloted

nut until snug, then back off approximately 1 /3 turn

or until one of the slots on the slotted nut lines up

with the hole in the axle.

Check

the

assembly

of

the

wheels.

There

should

be no side to side play, and the wheel should spin

freely.

Place

hub

caps

in

position

on

wheels

and

tap

on

with a rubber mallet or plastic hammer.