To transport log spliher, Adjustment, Splining wedge – MTD 241-521-000 User Manual

Page 10: Carburetor adjustment, Maintenance, Reservoir fluid, Hydraulic filter

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

WARNING: If the fluid becomes exce!isive>

ly hot at any time during operation, stop

the unit and ailow the fluid to cool c own.

Maximum performance will not be ol Gain

ed from your log splitter if the fluid is too

hot. Use extreme caution as contactir g hot

fluid could result in serious personal

injury.

TO TRANSPORT LOG SPLIHER

1.

Lower

the

beam

to

its

horizontal

position.

Make

certain the beam is latched securely with th(> lock

ing rod.

2.

Remove

the

quick

release

pin

which

secures

the

jack

stand.

Pivot

it

up

against

the

tongue,

and

secure with the quick release pin.

3.

Attach

the

hitch

to

a

towing

vehicle,

making

cer

tain

to

latch

securely.

Attach

the

safety

chains

to

the towing vehicle.

ADJUSTMENT

A

WARNING: Always stop the engine > and

disconnect the spark plug wire befont per

forming any adjustments.

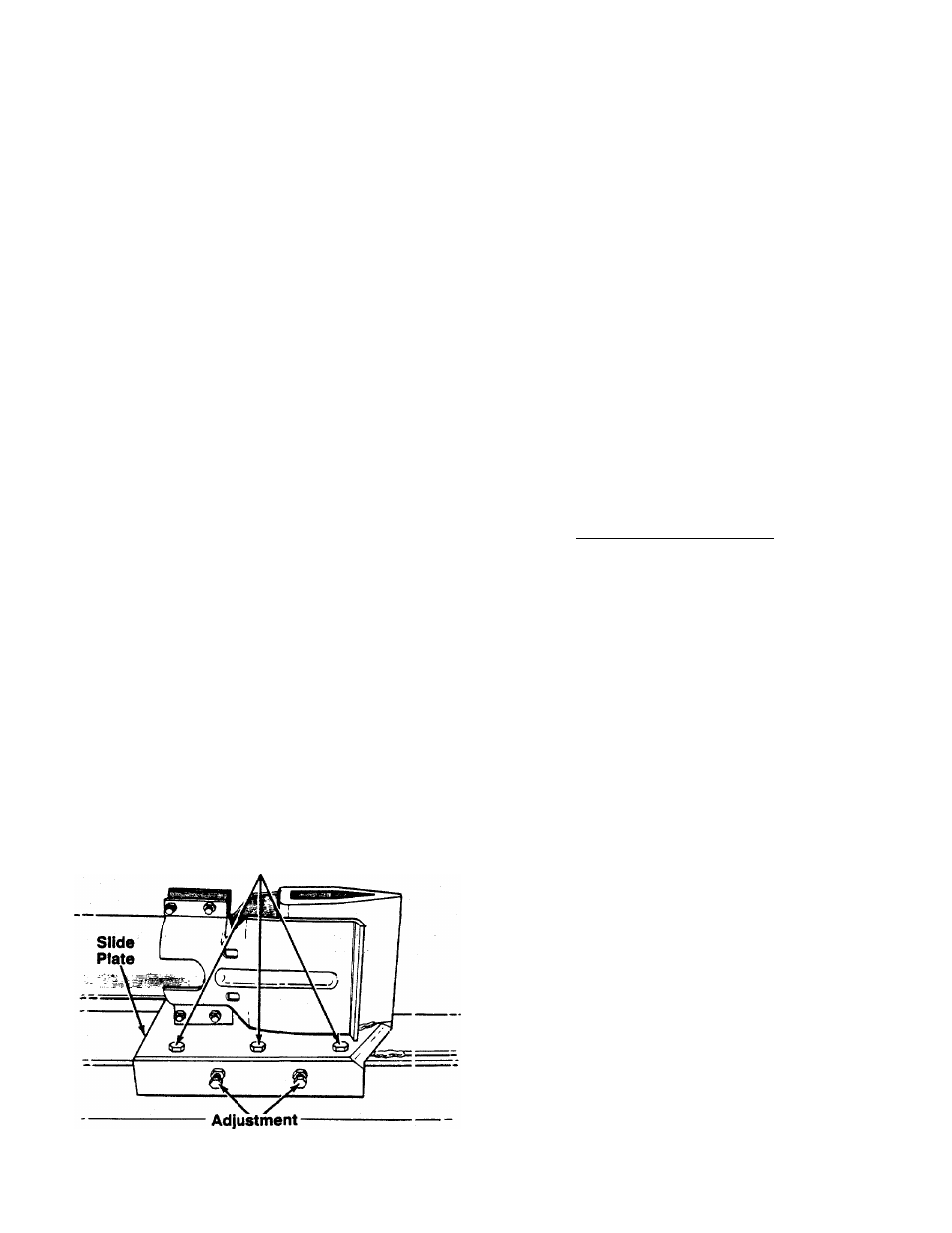

SPLiniNG WEDGE

As

normal

wear

occurs,

periodically

adjust

the

belts

on

the slide plate (beneath

the splitting wedge) as fc Hows

to

eliminate

the

excess

space

between

the

wedge

plate

and the beam. See figure 15.

1.

Loosen the three hex bolts on top of the slide plate

(beneath the splitting wedge).

2.

Back the two adjustment bolts on the side of the

slide plate out

slowly

until the wedge assembly will

slide on the beam. Tighten the lock nuts sec urely

against the base of the slide plate to hold the bolts

in this position.

3.

Retighten the three hex bolts on top of the slide

plate.

Hex Bolts

CARBURETOR ADJUSTMENT

A

WARNING: If any adjustments are made to

the engine while the engine is running

(e.g. carburetor), keep dear of all moving

parts. Be careful of heated surfaces and

muffler.

Minor

carburetor

adjustment

may

be

required

to

com

pensate

for

differences

in

fuel,

temperature,

altitude

or

load.

Improper

adjustment

will

cause

stalling

when

split

ter

is

under

load,

hard

starting

and

higher

fuel

con

sumption.

Refer

to

the

separate

engine

manual

packed

with

your

log splitter for carburetor adjustment information.

NOTE:

A dirty air cleaner will cause engine to run rough.

Be certain air cleaner is clean and attached to the car

buretor before adjusting carburetor. Do not make un

necessary adjustments. Factory settings are satisfactory

for most applications and conditions.

A

MAINTENANCE

WARNING: Always stop the engine and

disconnect the spark plug wire before per

forming any maintenance or repairs.

RESERVOIR FLUID

Check

the

hydraulic

fluid

level

in

the

log

splitter

reser

voir

tank

before

each

use.

Fiuid

level

should

be

1V

2

"

to 2" from the top of the tank.

Change

the

hydraulic

fluid

in

the

reservoir

every

100

hours

of

operation.

Disconnect

the

suction

hose

from

the bottom of the reservoir tank, and drain the fluid in

to

a

suitable

container.

Refill

using

only

Dexron

II

automatic

transmission

fluid

or

10W

non-foaming

hydraulic

fluid,

as

instructed

in

the

“Initial

Preparation”

section

of

this

manual,

page

8.

Also,

make

certain

to

change the hydraulic filter.

NOTE:

Drain the fluid and flush the reservoir tank and

hoses with kerosene whenever any repair work is per

formed on the tank, hydraulic pump or valve. Con

taminants in the fluid will damage the hydraulic

components. (Should be performed by an authorized

service dealer.)

A

WARNING: Use extreme caution when

working with kerosene, as it is an extreme-

iy flammable fluid.

FIGURE 15.

Bolts

HYDRAULIC FILTER

Change

the

hydraulic

filter

every

50

hours

of

operation.

Use only a 10 micron hydraulic fiiter. Order part number

723-0405.

10