To operate log spliher, To transport log spliher, Adjustments – MTD 638 User Manual

Page 11: Splining wedge

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

TO OPERATE LOG SPLIHER:

1. Set throttle at maximum speed.

2. Place the log upright, on top of end plate for verti

cal operation, and on top of beam for horizontal

operation.

3. Push the control handle in forward position until

the splitting wedge just contacts the log. Release

the control handle.

4.

5.

Step behind the reservoir tank (see figures 13 or

14) and push the control handle in forward posi

tion until the log is split.

Move the control handle to reverse position to

return the splitting wedge.

A

WARNING: If the fluid becomes exces

sively hot at any time during operation,

stop the unit and allow the fluid to cool

down. Maximum performance wili not be

obtained from your log splitter if the fluid

is too hot. Use extreme caution as con

tacting hot fluid could result in serious

personal injury.

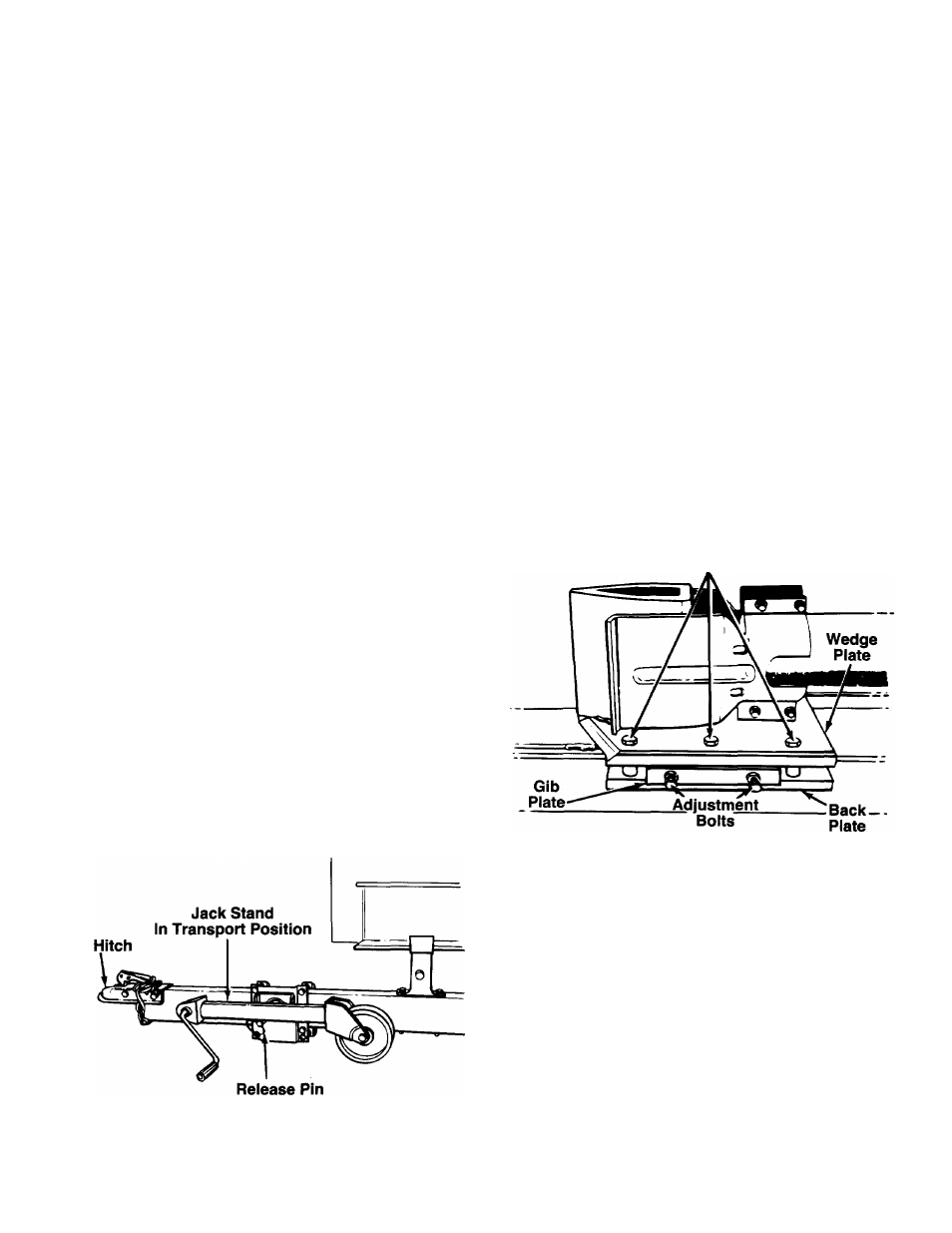

TO TRANSPORT LOG SPLIHER

1. Unlock the beam from the vertical position by

pulling out on the locking rod and pivoting it to the

right.

2. Lower the beam to its horizontal position. Make

certain the beam is latched securely with the ver

tical position release rod.

3. Raise or lower jack stand to attach the hitch to a

towing vehicle. Make certain to latch securely.

Attach the safety chains to the towing vehicle.

4. Raise the jack stand wheel to its highest position.

Pull out on release pin and pivot the jack stand

until it locks in the horizontal position. See figure

16

.

ADJUSTMENTS

A

WARNING: Always stop the engine and

disconnect the spark plug wire before

performing any adjustments.

2

.

SPLiniNG WEDGE

As normal wear occurs, periodically adjust the bolts

on the side of the wedge plate as follows to eliminate

the excess space between the wedge plate and the

beam. See figure 17.

1. Loosen the three hex bolts on top of the wedge

plate (beneath the splitting wedge).

Loosen the lock nuts on the two adjustment bolts

on the side of the gib plate, located beneath the

splitting wedge. Turn the adjustment bolts in until

snug, then back them off slowly until the wedge

assembly will slide on the beam.

Tighten the lock nuts securely against the gib

plate to hold the adjustment bolts in this position.

Retighten the three hex bolts on top of the wedge

plate.

3.

4.

Hex Bolts

FIGURE 16.

FIGURE 17.

Periodically remove and replace the “gibs” (spacers)

between the wedge plate and the back plate as fol

lows.

NOTE: If desired, the gibs may be rotated and/or

turned over for even wear.

1. Remove the center bolt on top of the wedge

plate. Slide the gib plate out. See figure 17.

2. Remove and replace the gibs. Reassemble the

gib plate, making certain flat washers are in place

under the gib plate.

3. Readjust the bolts on the side of the wedge plate

as instructed above.

11