Note, Throttle control adjustment, Cable clamp screw – MTD 219-406-000 User Manual

Page 13: Figure 23, Lubrication, Warning, Important, Trouble shooting, Engine, Cleaning the tine area

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

NOTE

A dirty air cleaner will cause engine to

run rough. Be certain air cleaner is

clean and attached to the carburetor

before adjusting carburetor. Do not make

unnecessary

adjustments.

Factory

settings are satisfactory for most appli

cations and conditions.

THROTTLE CONTROL ADJUSTMENT

To obtain satisfactory engine performance, the engine

throttle control must be adjusted properly. If it is

necessary to check the engine control adjustments,

proceed as follows.

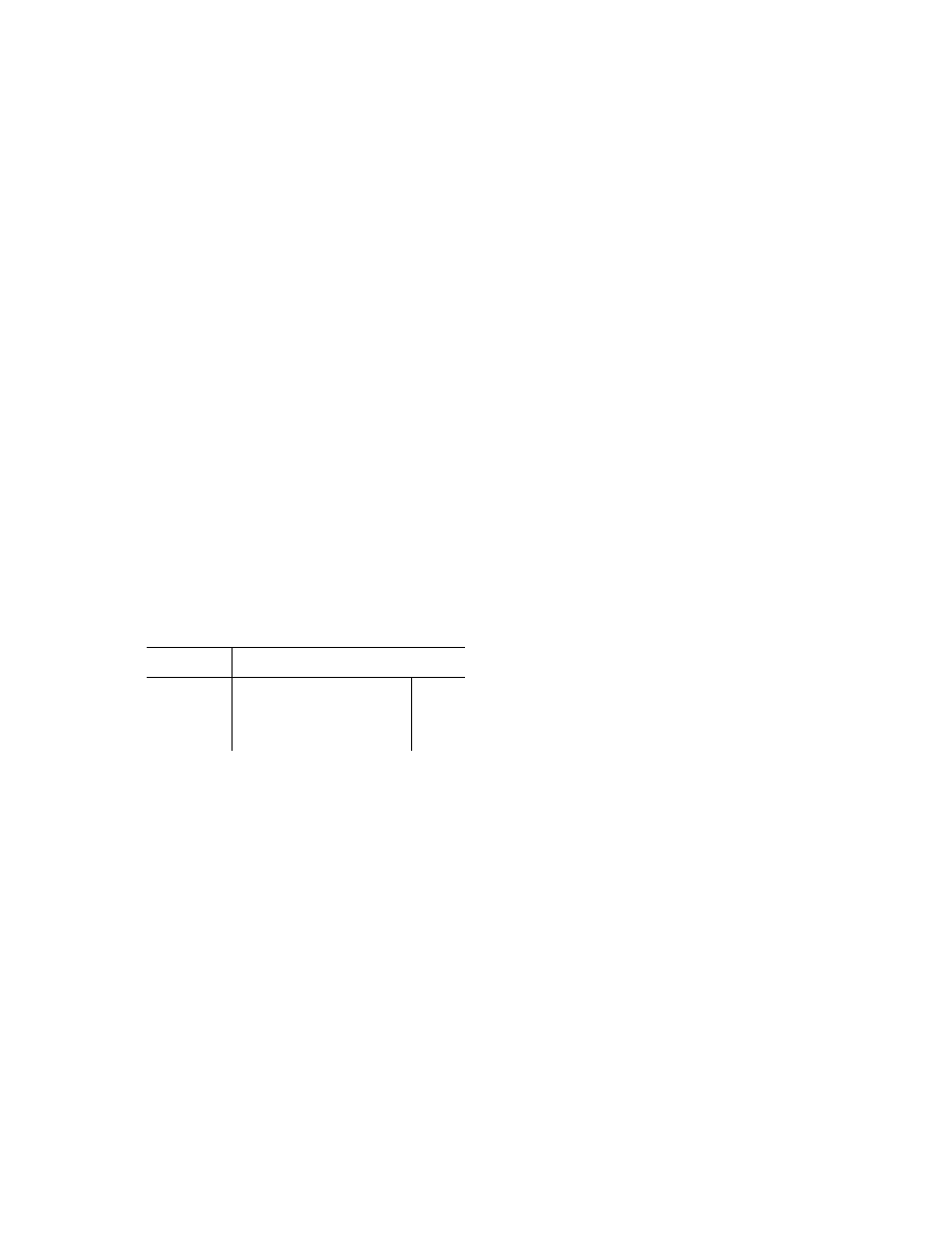

1. Loosen the cable clamp screw. See figure 23.

2. With the throttle control in FAST position and the

cable connected to the adaptor lever, push the

cable through the cable clamp in the direction

shown in figure 23 until the adaptor lever is as far

up as it will go.

3. Tighten the cable clamp screw.

4. Check that the engine stops when throttie control

is moved to STOP position. If engine does not stop,

loosen the cable clamp screw and readjust by pull

ing cable backward slightly until engine stops.

Retighten cabie clamp screw.

Cable

'Adaptor

Lever

Cable Clamp

Screw

FIGURE 23.

LUBRICATION

Ar

WARNING i

♦♦♦♦♦♦♦♦♦

Always stop engine and disconnect spark

plug wire before cleaning, lubricating

or doing any kind of work on tiller.

Chain Cases—The chain cases are pre-lubricated and

sealed at the factory. They require no checking unless

the chain cases are dissassembled. To fill with grease,

lay the left half of the chain case on its side. Add 12

ounces of plastilube

#0

grease to the tine chain case

or 10 ounces to the wheel chain case. Assemble the

right half to it. This grease can be obtained at your

nearest

authorized

dealer.

Order

part

number

737-0133.

Wheels—Lubricate the wheel bearings with a light oil

after each fifteen hours of operation.

Clutch Controls—Lubricate the pivot points on the

clutch levers and the cables at least once a season with

light oil. The controls must operate freely in both

directions.

Pivot Points—Lubricate ail pivot points and linkages

at least once a season with light oil.

MAINTENANCE

At-

WARNING

Disconnect the spark plug wire and

ground it against the engine before

performing

any

repairs

or

main

tenance.

IMPORTANT

If for any reason the tines are re

moved from the tilier, be certain the

tines are reassembled so that the

sharp edge of the tines enter the

soil

first.

Refer

to

item

number

one under “Operation.”

TROUBLE SHOOTING

Refer to page 22 of this manual for trouble shooting

information.

ENGINE

Refer to the separate engine manual for all engine

maintenance instructions.

Maintain

engine oil as instructed in the separate

engine manual packed with your unit. Read and follow

instructions carefully.

Service

air cleaner every 25 hours under normal con

ditions. Clean every few hours under extremely dusty

conditions. Poor engine performance and flooding

usually indicates that the air cleaners should be ser

viced. To service the air cleaner, refer to the separate

engine manual packed with your unit.

The

spark plug should be cleaned and the gap reset

once a season. Spark plug replacement is recom

mended at the start of each tilling season; check engine

manual for correct plug type and gap specifications.

CLEANING THE TINE AREA

Clean the underside of the tine shield after each use.

The dirt washes off the tines easier if washed im

mediately instead of after it dries.

13