MTD 112-530A User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

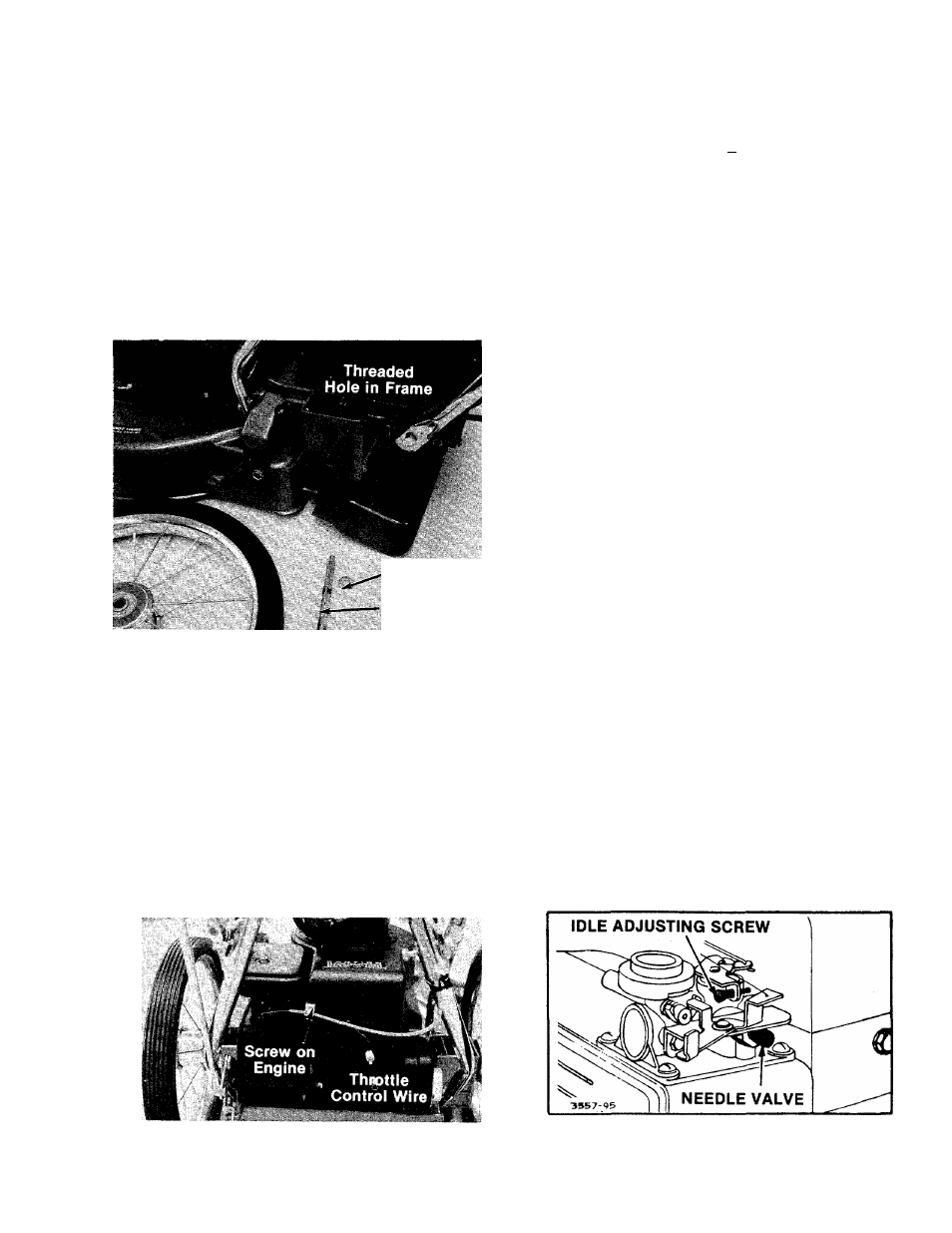

CUTTING HEIGHT

The mower can be adjusted to four different cut

ting heights. Cutting height adjustment is made

by removing and moving axie bolts to the desired

positions. Ail axle bolts must be mounted in the

same relative position to the deck. When wheels

are mounted to the deck, the bellevMIe washers

must be assembled with the cupped side towards

the deck. This is necessary to prevent the axle

bolts from loosening. When assembling the rear

wheel, bellevMIe washers are placed against the

threaded hole in the frame. See figure 13.

Beileviile

Washer

Axle Bolt

FIGURE 13.

THROTTLE

If adjustment becomes necessary, the throttle

control wire assembly can be reset as follows:

1. Loosen, but do not remove, screw securing

throttle control wire assembly at engine. See

figure 14.

2. Move throttle control lever on handle to

“CHOKE” position.

3. Move lever, to which control wire is fastened

at engine, to full open position. Retighten

screw

to

secure

throttle

control

wire

assembly.

i. t

If any adjustments are made to the

engine while the engine is running

(e.g. carburetor), disengage all

clutches and blades. Keep clear of

all moving parts and be careful of

heated surfaces and muffler.

CARBURETOR ADJUSTMENTS (See Figure 15)

Minor carburetor adjustment may be required to

compensate for differences in fuel, temperature,

altitude and load.

Initial Adjustment:

Turn needle valve clockwise to close it. Then open

2 turns. This initial adjustment will permit the

engine to be started and warmed up before mak

ing final adjustment.

Final Adjustment:

With engine running at normal operating speed

(approximately 3000 RPM without load), turn nee

dle valve clockwise until engine starts to lose

speed (lean mixture). Then slowly turn needle

valve

counterclockwise

past

the

point

of

smoothest operation, until engine just begins to

run unevenly. This mixture will give best perform

ance under load.

To check adjustment, move engine control from

SLOW to FAST speed. If engine tends to stall or

die out, it usually indicates that the mixture is

slightly lean. It may be necessary to open the nee

dle valve slightly to provide a richer mixture. This

richer mixture may cause a slight unevenness in

idling.

FIGURE 14.

FIGUREIS.