Lubrication, Maintenance – MTD 112-530A User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

LUBRICATION

IMPORTANT

Always stop engine and disconnect

spark plug wire before cleaning,

lubricating or doing any kind of

work on lawn mower.

Blade Spindle Assembly—The blade spindle

assembly is equipped with a grease fitting. Use

grass discharge chute for access to the fitting

located under the deck. Use multi-purpose grease.

Lubricate PRIOR to initial use and every 25 hours

thereafter.

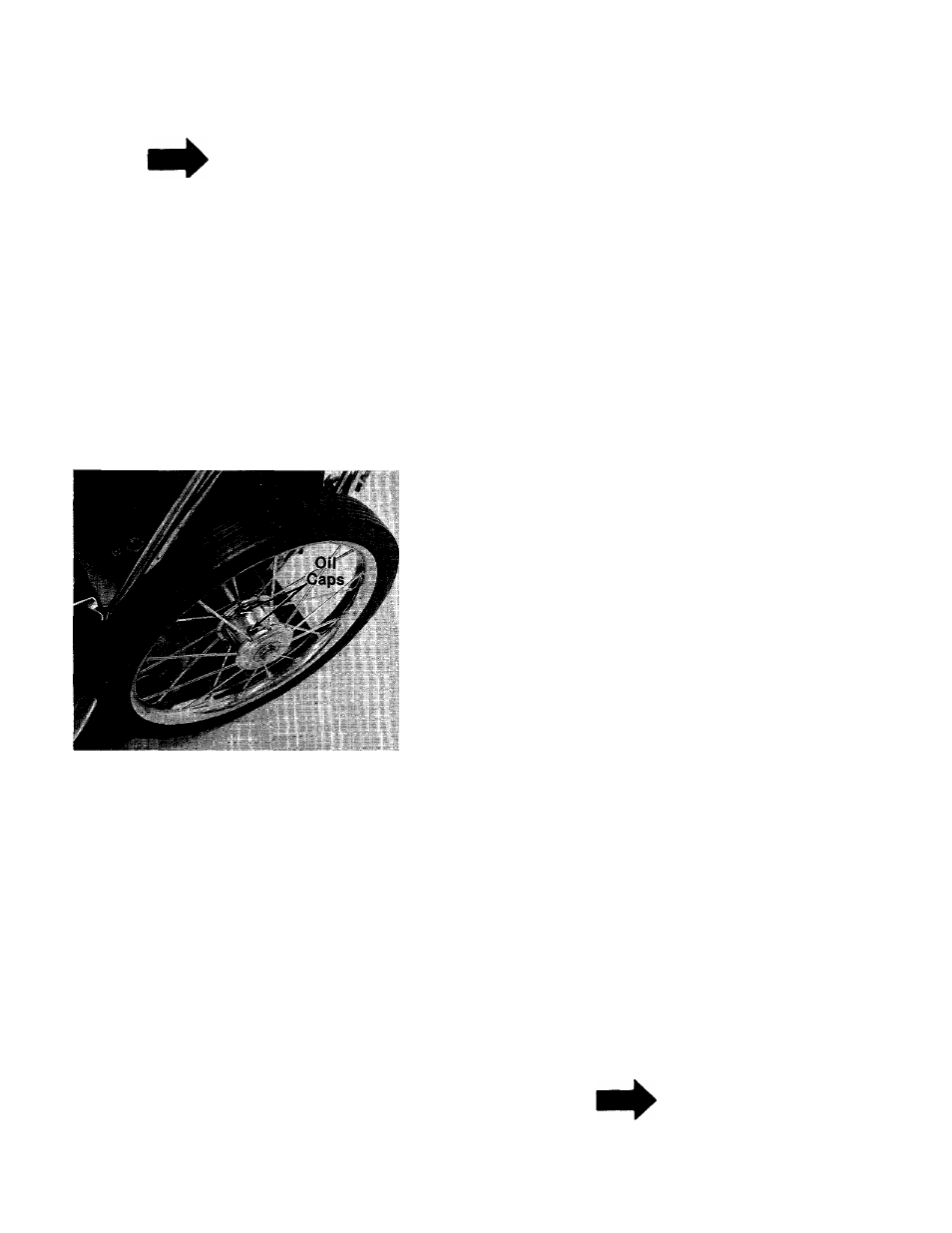

Wheels—Unit is provided with ball bearing

wheels. Lubricate at least once a season with light

oil. To lubricate the rear wheels, remove the oil

caps and add several drops of oil. See figure 16.

Also, if the wheels are removed for any reason,

lubricate the surface of the axle bolt and the inner

surface of the wheel with light oil. A 4 oz. plastic

bottle of light oil lubricant is available. Order part

number 737-0170. Engine oil may also be used.

MAINTENANCE

CUTTING BLADE

A. Removal for Sharpening or Replacement

\

WARNING J

Be sure to disconnect and ground

the spark plug wire before working

on the cutting blade to prevent

accidental engine starting.

1. Remove the large bolt and lock washer which

holds the blade and adapter to the blade spin

dle.

2. Remove the blade and adapter from the spin

dle. Be careful not to lose the key on the spin

dle.

3. If the blade or blade adapter needs replacing,

remove the two small bolts, lock washers and

nuts which hold the blade to the adapter.

FIGURE 16.

Protective Shield—The pivot points on the protec

tive shield should be lubricated periodically with

light oil to prevent any rust or binding.

Chute Deflector—The torsion spring and pivot

point should be lubricated periodically with light

oil to prevent any rust or binding. Deflector must

work freely.

Engine—Follow engine manual for lubrication in

structions. Check oil level before each use.

Throttle—Periodically lubricate throttle control

lever and throttle wire assembly with a few drops

of light oil for ease of operation.

Friction point between idler bracket assembly

(Ref. No. 9 on page 15) and deck should be

greased once each season with a multi-purpose

grease.

B. Sharpening

Remove the cutting blade by following the direc

tions of the preceding section.

When sharpening the blade, follow the original

angle of grind as a guide. It is extremely important

that each cutting edge receives an equal amount

of grinding to prevent an unbalanced blade. An un

balanced blade will cause excessive vibration

when rotating at high speeds, may cause damage

to the mower and could break, causing injury.

The blade can be tested for balance by balancing

it on a round shaft screwdriver. Remove metal

from the heavy side until it balances evenly.

NOTE

It is recommended that the blade

always be removed from the adapter

for the best test of balance.

10