Carburetor adjustments, Pressure relief valve setting, Maintenance – MTD 24642-A User Manual

Page 8: T warning i, Engine oil, Log splitter reservoir oil, Adjustments

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

ADJUSTMENTS

1. Block up front of log splitter so beam is level.

CARBURETOR ADJUSTMENTS

Refer to engine manual packed with your unit for

carburetor adjustment information.

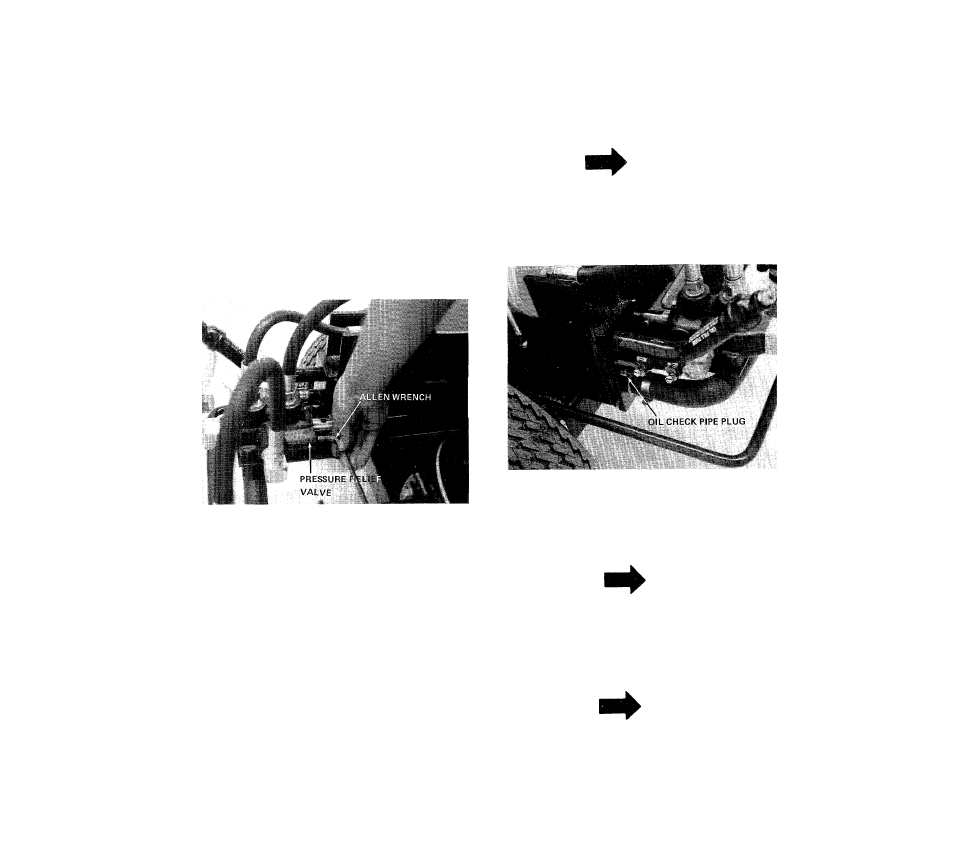

PRESSURE RELIEF VALVE SETTING

If the pressure relief valve is set too low, it will open

up before enough pressure is built up to properly

operate the ram. See figure 14.

To set the pressure relief valve:

1. Have someone place a log crossways in the splitter

and allow the ram to push against it with the

engine at full throttle.

2.

If the engine begins to labor, the relief valve

setting is correct.

3.

If adjustment is necessary, tighten the screw until

the engine begins to labor.

FIGURE 14

MAINTENANCE

t WARNING i

^ ^ ^ ^ ^ ^ ^

^

Always stop engine and disconnect

spark plug wire before performing any

maintenance or adjustments.

ENGINE OIL

Change oil first two (2) hours of operation and

check oil level every five (5) operating hours or each

time equipment is used.

Change oil every twenty-five (25) operating hours

or sooner if equipment is operated in extremely

dusty or dirty conditions.

Refer to engine manual for quantity and type of oil.

LOG SPLITTER RESERVOIR OIL

Check oil in log splitter reservoir before every use.

See figure 15.

2. Remove check pipe plug in rear of beam. See

figure 15. If oil starts to come out of check pipe

plug hole, oil level is correct. IF IT DOES NC'^

add oil to breather tube (see figure 7) until o

starts out.

NOTE

Use hydraulic sealant tape or pipe

sealant on pipe plug threads.

3. Replace check pipe plug. Remove block from

under front of beam.

FIGURE 15

Change oil in the reservoir every (100) hours of

operation.

1. Remove the hose clamp at inlet hose (bottom

hose on rear of beam). See figure 16.

NOTE

Be prepared to catch oil in a suitable

container.

Pull off inlet hose from strainer tube assembly and

catch oil in a suitable container. See figure 16.

With an adjustable wrench remove the strainer

tube assembly. See figure 16.

2

.

3.

4.

5.

NOTE

The strainer tube assembly is 53" long.

Drain oil, clean strainer tube and reassemble-

using a hydraulic pipe sealant on the threads.

Remove the breather plug from breather tube.

See figure 7. Pour approximately 3 gallons of

Dexron transmission fluid ONLY into breather

tube.