Tire pressure, Operation, Before starting – MTD 24642-A User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HAI'/iMER

FIGURE 4

ENGAGEMENT HANDLE

ENGAGEMENT ROD

HAIR PIN COTTER

FERRULE

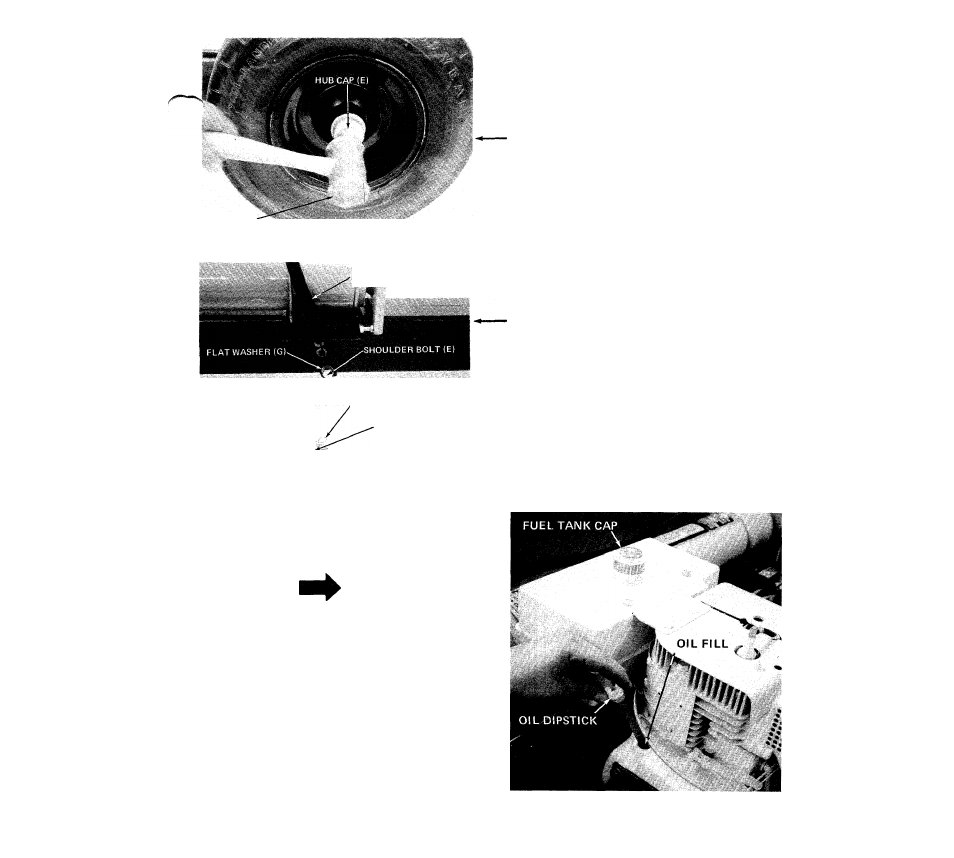

4. Place hub cap (E) in position on wheel and tap on

with a plastic hammer. See figure 4.

5. Repeat steps 1 through 4 for the second wheel.

6. Secure engagement handle to beam with shoulder

bolt (F) and flat washer (G). See figure 5.

7. Remove the hair pin cotter from ferrule.

8. Secure engagement rod to engagement handle

with hair pin cotter. See figure 5.

TIRE PRESSURE

FOR SHIPPING PURPOSES, THE TIRES ON YOUR

UNIT MAY BE OVER-INFLATED. TIRE PRESSURE

SHOULD BE REDUCED BEFORE UNIT IS PUT

INTO OPERATION. RECOMMENDED PRESSURE

SHOULD BE APPROXIMATELY 15 P.S.I. EQUAL

TIRE PRESSURE SHOULD BE MAINTAINED ON

ALL TIRES. MAXIMUM TIRE PRESSURE IS 30

P.S.I.

FIGURES

OPERATION

BEFORE STARTING

NOTE

Refer to engine manual packed with

log splitter for complete instructions

for the care and maintenance of engine.

READ DIRECTIONS CAREFULLY.

1. Fill oil sump with approximately 1-1/2 pints of

SAE 30 oil, or to full mark on dipstick. See Figure

6.

Use MS classification oil. Do not use oils

marked only MM or ML or unmarked. Above

32°, use SAE 30; below 32° use SAE 10W-30.

These recommendations must be followed for

\ best performance and long life.

During initial break-in period, oil level should be

watched closely. Refer to the engine manual.

2. Fill fuel tank, using clean, fresh,

regular

grade

automotive gasoline. Fill tank completely.

FIGURE 6