Beam and splitting wedge, Hdse clamps, Engine – MTD 242-630-000 User Manual

Page 11: Flexible pump coupler, Pump, Tire pressure, Installation of tire to rim

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

BEAM AND SPLITTING WEDGE

Lubricate both sides of the beam where it contacts the

splitting wedge with engine oil before each use to

obtain years of service. However, normal wear will

occur. The wedge plate on the log splitter is designed

so the gibs on the side of the wedge plate can be eas

ily removed and rotated and/or turned over for even

wear. Make certain to readjust the adjustment bolts so

wedge moves freely, but no excess space exists

between the wedge plate and beam.

HDSE CLAMPS

Check the hose clamps on the suction hose (attached

to bottom of the pump) for proper tightness before

each use. Check the hose clamps on the return hose

at least once a season.

ENGINE

Refer to the separate engine manual for all engine

maintenance Instructions.

Maintain engine oil as instructed in the separate

engine manual packed with your unit. Read and follow

instructions carefully.

Service air cleaner every 25 hours under normal con

ditions. Clean every few hours under extremely dusty

conditions. Poor engine performance and flooding

usually indicates that the air cleaner should be ser

viced. To service the air cleaner refer to the separate

^ engine manual packed with your unit.

The spark plug should be cleaned and the gap reset

once a season. Spark plug replacement is recom

mended at the start of each season; check engine

manual for correct plug type and gap specification.

Clean the engine regularly with a cloth or brush.

Keep the cooling system (blower housing area) clean

to permit proper air circulation which is essential to

engine performance and life. Be certain to remove all

dirt and combustible debris from muffler area.

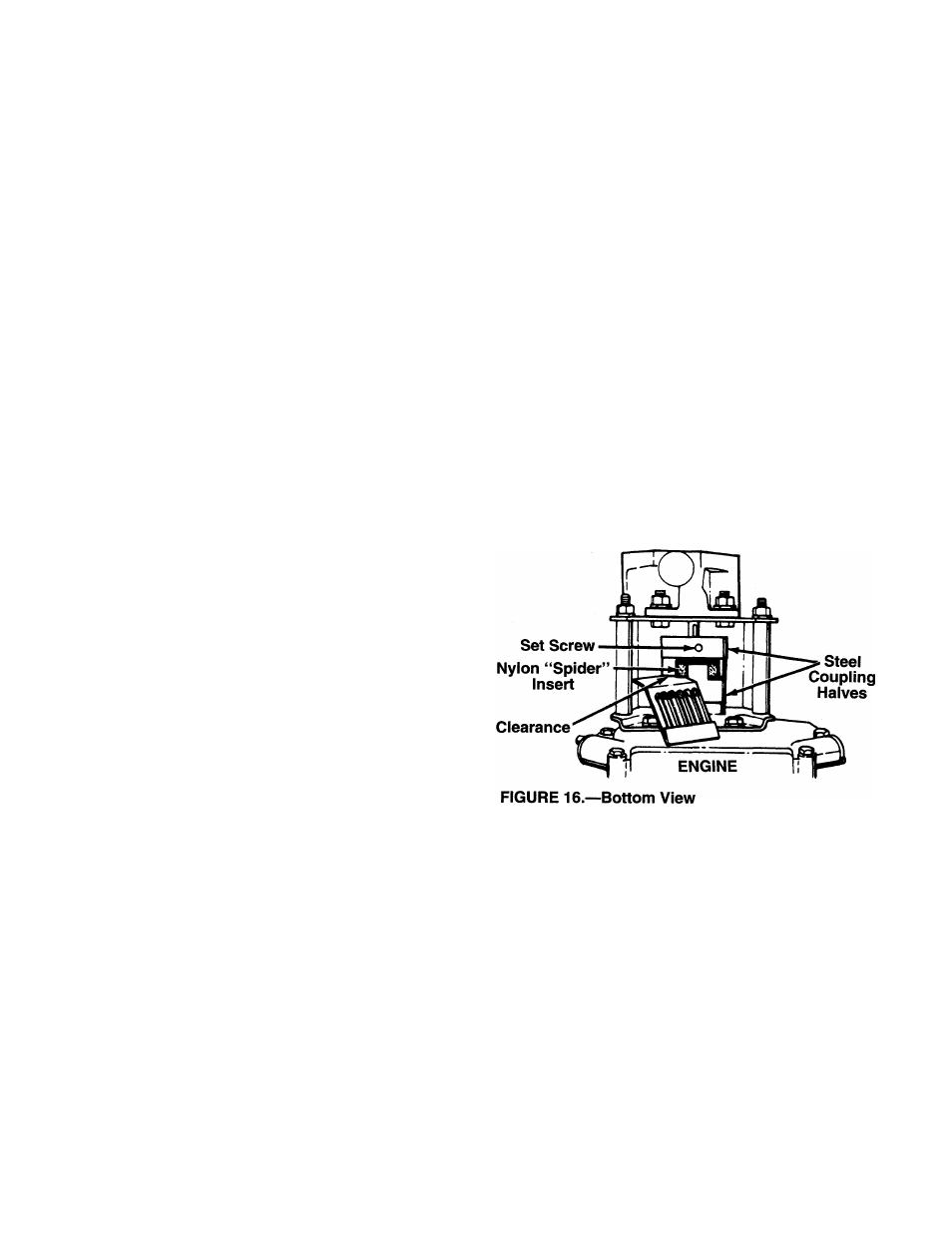

FLEXIBLE PUMP COUPLER

The flexible pump coupler is a nylon “spider” insert,

located between the pump and engine shaft. The align

ment is very critical. Over a period of time, the coupler

will harden and deteriorate. For a replacement flexible

pump coupler, order part number 717-0891.

IMPORTANT: Never hit the pump shaft in any

manner, as any blow will cause permanent dam

age to the pump.

When replacing the flexible pump coupling, proceed

as follows.

1. Place the coupling half onto the engine shaft.

^ Make certain there is clearance between the cou

pling half and the engine. Tighten the set screw.

2. Mount the pump onto the coupling support brack

et. Tighten securely.

3. Carefully slide coupling half onto pump shaft

(make certain set screw is loose). Slide the key

into place on the shaft.

4. Install the nylon “spider” insert into coupling half

on the engine shaft.

5. Place the coupling shield in position on the hex

bolts. Rotate the keyway on the pump shaft so it

is toward the bottom.

6. Attach the coupling support bracket to the hex

bolts, carefully sliding the coupling half over the

“spider” insert. Secure coupling shield and cou

pling support bracket with lock washers and hex

nuts. Tighten securely.

7. Adjust the two coupling halves (steel) so there is

between .010" and .060" clearance between the

two halves (at least the thickness of a matchbook

cover, up to 1/16" maximum). See figure 16.

Tighten the set screw in the coupling half on the

pump shaft.

NOTE:

M a k e c e rta in p ro p e r cle a ran c e is o b ta in e d

b e fo re tig h te n in g s e t sc re w .

PUMP

TIRE PRESSURE

Check sidewall of tire for manufacturer’s recommend

ed maximum tire pressure. If this information does not

appear on your tire, maximum tire pressure under any

circumstances is 30 p.s.i. Equal pressure should be

maintained on both tires.

INSTALLATION OF TIRE TO RIM

A

WARNING: The following procedure must

be followed when removing or installing

a tire to the rim.

1. Be certain rim is clean and free of rust.

2. Lubricate both the tire and rim generously.

11