7 specifications – Generac Power Systems GUARDIAN 04137-0 User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

GENERAL

INFORMATION

Section 1 — General information

Guardian Liquid-cooied 8 kW Generators

» 1.6.3 LOW COOLANT LEVEL SWITCH_____________ _

Should tlie .engine coolant level drop below tloe level

of’the high coolant temperature switch, it is possible

for the engine to overheat wltlaout automatic shut

down. To prevent such overheating without automat

ic shut down, the engine has a low coolant level sen

sor. If the engine coolant drops too low, the engine

automatically shuts down.

# 1.6.4 0¥ERSPEE0 SHUTDOWN______________ __

The DC control circuit board (inside control panel)

senses engine speed from the frequency of the

alternator AC output. Should the alternator output

frequency exceed approximately 72 Hertz (2,160

alternator rpm), circuit board action initiates an

automatic engine shutdown.

# 1.6.5 OVERCRANK SHUTDOWN________________

After 90 seconds of crank-rest cycles (while in Auto

mode], this function ends cranking if the engine

fails to start in that 90-second span.

1.7

SPECIFICATIONS

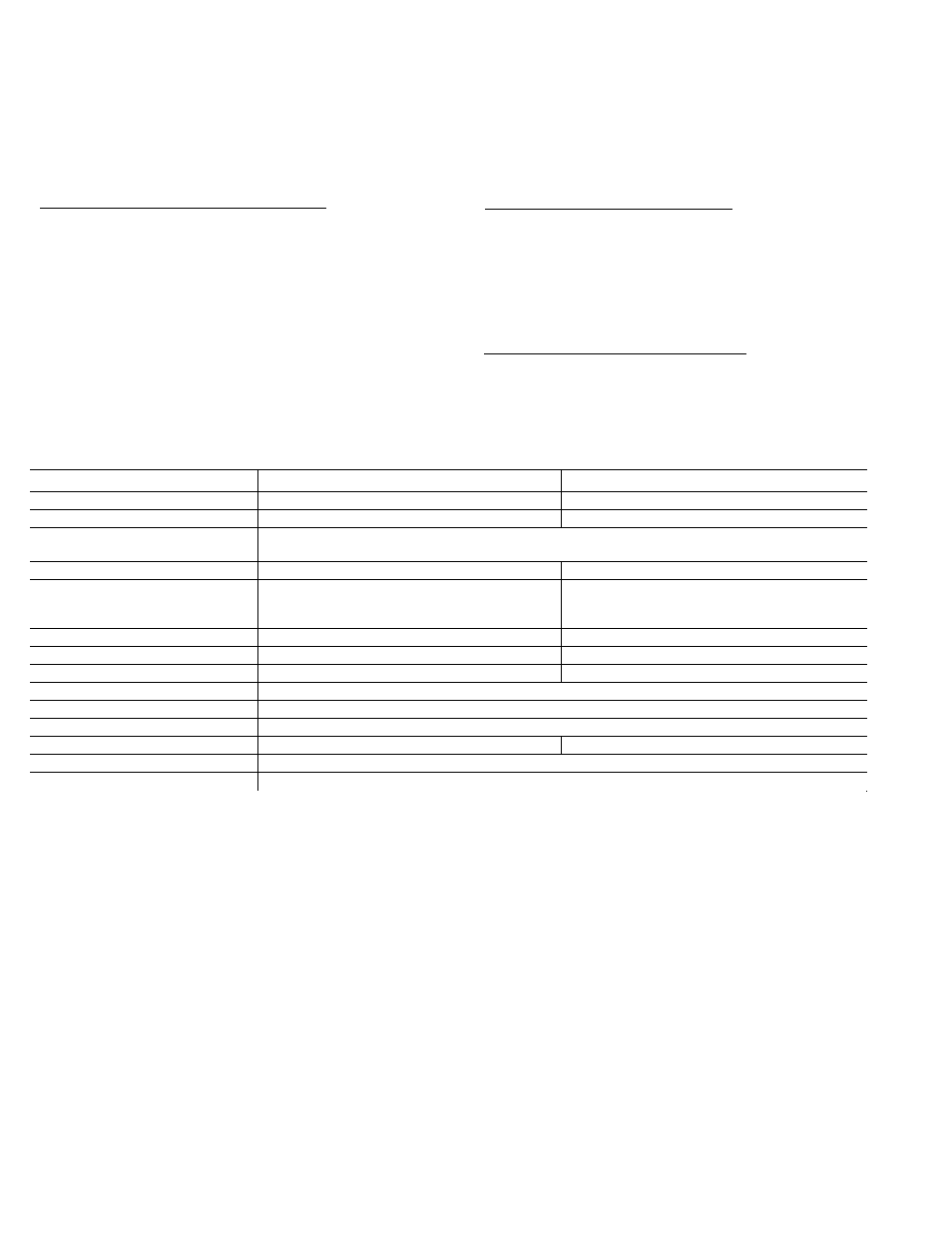

♦ 1.7.] GENERATOR

SINGLE-PHASE

THREE-PHASE

Model

04136-0

04137-0

Rated

Maximum

Continuous

AC Power Outnut (kW)*

8

Rated Voltage (volts)

120/240

120/208

Rated

Ma:d.mum

Continuous

Current at ...

»240 Volts, Single-phase (amps)

33.3

NA

»240 Volts. Tlcxee-phase (amps)

NA

24,1

•208 Volts, Three-phase (amps)

NA

27.8

Power Factor

1.0

0.8

Rated AC Frequency

60 Hertz at 1,800 rpm

Number of Rotor Poles

4

Rotor Speed at No Load

1,860 rpm

Type of Stator

'Four-wire

12-'wire Reconnectable

Rotor Excitation Svstem

Direct Excited Brush-h/pe Svstem

Rotor and Stator Insulation

Class “F”

'“Rated p)wer of geneiator is subjeci to and limited by such iactom as ambient leinperature, altitude, engine condition and otiier factoi-s. Engine power will deci-ease about 3.5

percent for eacti 1,000 feet above sea le/el; and also will dettrease an additional 1 percent for each 12° C (10° F) above 15.5° C (60° Fj. Maximum output power of the generator is

hmited by maximum engine power.

♦ 1.7.2

engine

’

Make ............................................................................ISM Diesel

Cylinder Arrangement............................ ........................ 3, in-line

Displacement.................................................

58.2

inches (954 cc)

Bore ............................................................ 2.95 inches (75 mm)

Stroke..............................................................2.85 inches (72 mm)

Compression Ratio............................................................... 23-to-l

Compression Pressure ar 200 rpm

Standard......................................................................426.7 psi

Minimum Limit.......................................................... 2S4.5 psi

Combustion Chamber Type ..................................Pre-Combustion

Firing Order ........................................................................... 1-2-3

Direction of Rotation ...........................................Counterdodvvise

NumAer of Main Bearings ........................................................... 4

No. of Teeth on Flywheel.......................................................... 104

Ground Polariw ................................................................ Negative

Oil Filter.......................................Full flow, woth byptass valve

Oil Pressure ....................................................................29-71 psi

Crankcase Oil Capacity

With Filter Change ........................... 4.0 U.S. quarts (3.8 L)

Whthout Filter Change...................... 3.7 U.S. quarts (3.5 L)

Recoznmended .Engine Oil.................See Section 1,9 (Pcige 7)

Type of Cooling System ....Pressurized, closed recovery

S Generac^ Power Svstems, !nc.

Type of Cooling Fan.......................................................... Pusher

Cooling System Capacity.................... 2.5 U.S. gallons (9.5 L)

Recommended Coolant ..................Use a 50-50 rnimire of low

silicate, ethylene glycol base

anti.iTeeze and soft water. See

Section 3.10 (Page 14),

Type of Fuel System............................................................. Diesel

Recommended Fuel ............................. See Section 1.8 (Page 7)

Fuel Filter...................................................................... 10 micron

Fuel Injection Pump ........................................... Bosch “M” Type

Injection Spray Angle............................................ 20°-21° BTDC

Injection Pressure ...........................................................1,707 psi

Fuel Consumption - 60 Hz (gal/h)

25% Load 50%Load 75% Load 100% Load

0.35

0,52

0.63

0.S4

NOTE:

Actual

fuel

consumption

obtained

may

vary

depending on such variables as applied load, ambi

ent

temperature,

engine

conditions

and

other

environmental factors.