Assembly & pre-service – Ariens 924071 User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

ASSEMBLY & PRE-SERVICE

WARNING: FAILURE TO FOLLOW ALL INSTRUCTIONS

FOR ASSEMBLY AND PRE-SERVICE COULD RESULT

IN PERSONAL INJURY AND/OR DAMAGE TO THE

SNO-THRO. CHECK AND TEST THE FUNCTION OF

ALL CONTROLS BEFORE STARTING ENGINE. BE SURE

TO FILL ENGINE WITH OIL.

WARNING: ALL ASSEMBLY AND ADJUSTMENT PRO

CEDURES ARE TO BE MADE WITH ENGINE STOPPED

AND SPARK PLUG WIRE DISCONNECTED.

NOTE: MAKE SURE ALL SAFETY DEVICES AND

GUARDS ARE IN POSITION AND OPERATING PROPER

LY. READ "INSTRUCTIONS FOR SAFE OPERATION"

BEFORE USING UNIT.

GENERAL

All hardware and parts required for assembly are ship

ped in the parts bag or are located, in place, on the

machine. The upper handlebars and panel are assem

bled at the factory with the two clutch rods and in

terlock system in place and adjusted. The lower

handlebars must be installed. The snow head and trac

tor are shipped assembled with lower shift rod in place.

Attachment clutch rod is in place on handle panel

ssembly.

Handlebar Assembly, Deflector and Discharge Chute,

Runners, Remote Deflector Control and Headlight must

be attached.

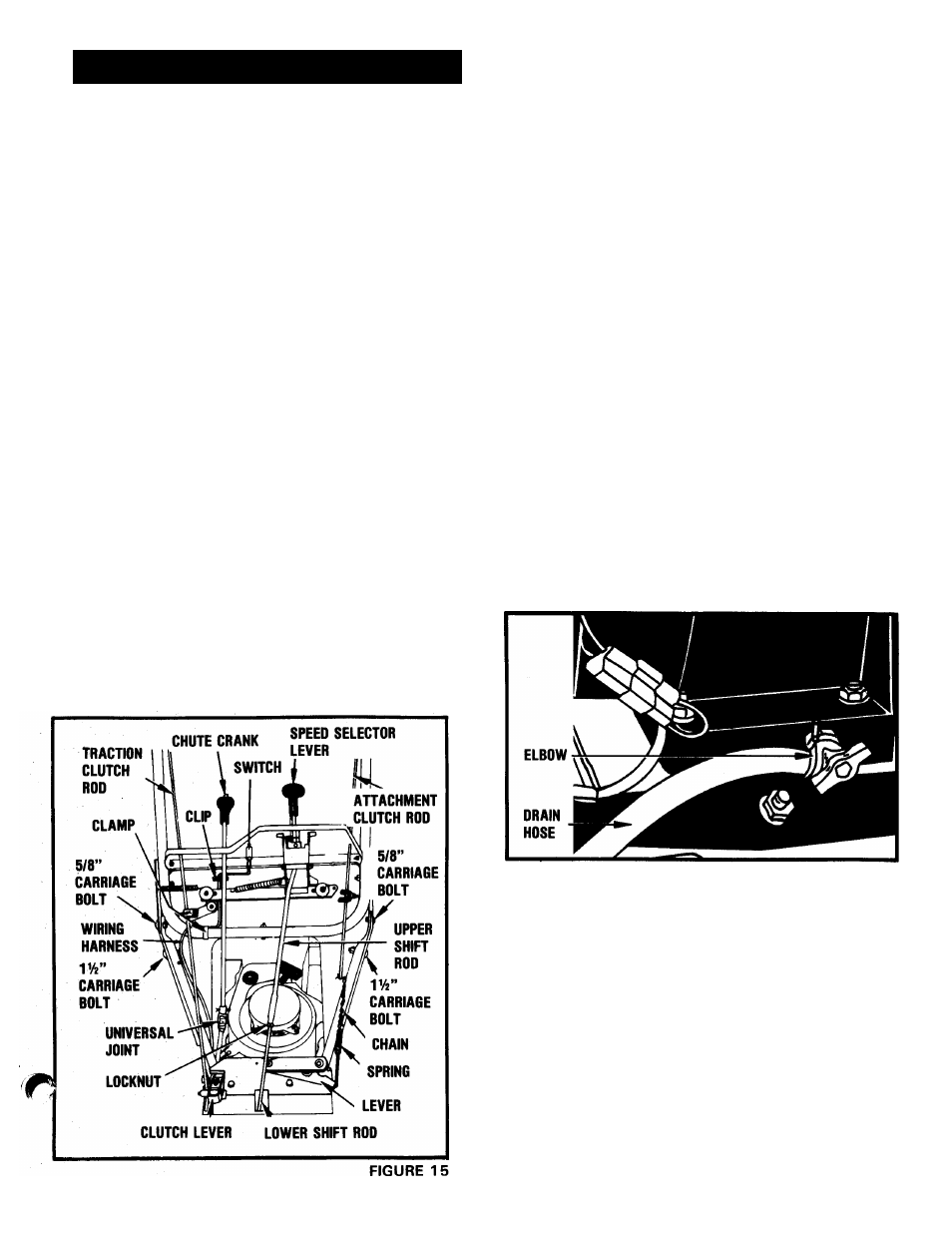

HANDLEBAR - FIGURES 15 & 22

Install the lower handlebars on the frame using the

studs and hardware in place on the frame. (Leave the

hardware loose on the studs until the upper handlebars

are installed). Be sure to install the chute crank bracket

on the left rear stud of handlebar when installing

handlebar. See "CHUTE CRANK" instructions.

Install the upper handlebar and panel on the lower

handlebars. Use a 5/8" carriage bolt and locknut in

each of the top holes, and a 1-1/2" carriage bolt and

locknut in each of the lower holes. With everything in

place, tighten all handlebar hardware.

ENGINE - FIGURES 1 & 16

1.

Remove oil drain plug from the right hand side of

engine base. Install reducer and elbow and tighten

until elbow outlet is toward rear of machine. In

stall drain hose with clamp onto elbow. See Figure

16. Remove plastic cover on oil fill tube and

discard.

2.

Add oil according to engine manufacturer's in

structions provided with the Sno-Thro. After fill

ing crankcase, insert dipstick into the oil fill tube.

See Figure 1. The dipstick is shipped with loose

parts in the parts container.

3.

Install throttle control knob from parts bag by

screwing it onto the rod protruding through the

top of the engine. See Figure 1.

FIGURE 16

CHUTE CRANK - FIGURES 15 & 17

The chute crank is packed separately in the carton. The

intermediate shaft, universal joints and chute crank

bracket are in place on the machine. The chute crank

bracket should be re-installed on the rear, left hand stud

at the time the handlebars are installed. Insert the chute

crank down into the hole in the handlebar panel and

connect to the universal joint on the intermediate shaft

with the hairpin cotter provided. See Page 12 illustra

tion also. After completing the chute crank connection,

check the alignment of worm and chute by rotating the

discharge chute through its full travel. (lihute should

rotate easily. If not, reposition worm as required and

adjust according to "CHUTE CRANK ADJUSTMENT"

instructions

in

"ADJUSTMENTS-MAINTENANCE"

section of this manual.

- 13 -