Maintenance – Ariens 931015 S-18 User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

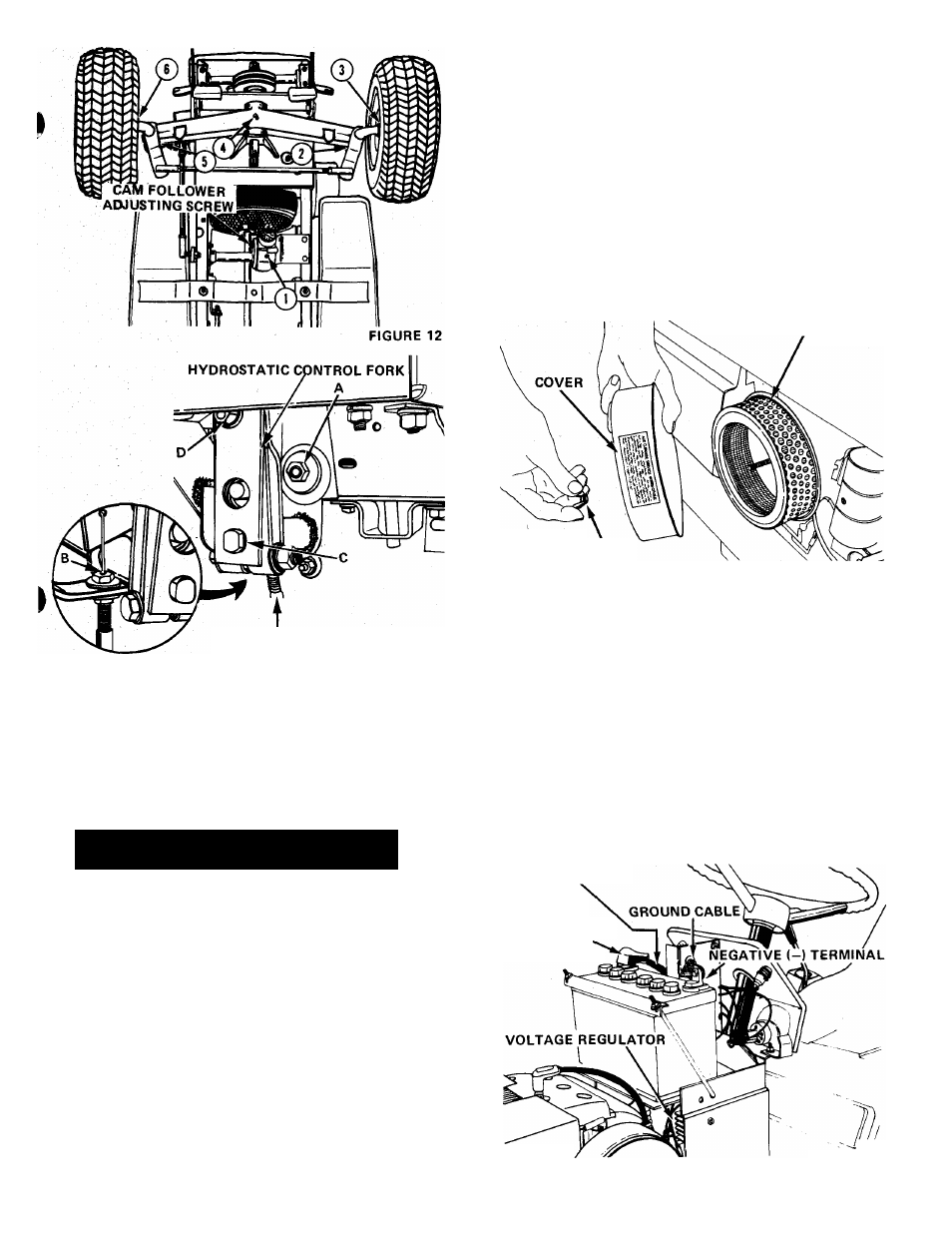

CONTROL CABLE

OIL HYDROSTATIC CONTROL LINKAGE

FIGUREIS

1. Oil the roller in the cam slotted plate shown in Figure 18

with a few drops of light oil every 25 hours of operation or

monthly.

2. Oil control cable B, Figure 13.

3. Periodically oil hydrostatic control pivot shaft at Point C,

Figure 13.

4. Periodically lubricate all lift linkage pivot areas.

MAINTENANCE

A

NOTE

THAT

ALL

ENGINE

SERIAL

NUMBERS

HIGHER THAN THOSE LISTED BELOW HAVE A

GOVERNOR

SETTING

OF

3250

RPM,

NO

LOAD

(+ 75 ROM). IDLE SET AT 1600 RPM, NO LOAD.

MODEL NO. K301S SERIAL NO. 8173991

MODEL NO. K321S SERIAL NO. 8117916

MODEL NO. K341S SERIAL NO. 8119833

MODEL NO. K361QS ALL ENGINES

12 H.P.

14 H.P.

16 H.P.

18 H.P.

HOUR METER

The hour meter is standard equipment on the Model

931015 and is available as an optional accessory for all other

models.

The hour meter is located under the engine hood, on the

right side, just ahead of the dash panel. The hour meter

will record the actual time the engine operates. Keep a record

of hour meter readings in order to perform Maintenance and

Lubrication services at the recommended hourly intervals.

AIR FILTER SERVICE

Check the air filter daily or every 5 hours of operation.

When operating in extremely dusty conditions, check the air

filter daily. A pre-cleaner is available.Consult the engine manual.

To clean the cartridge, remove the wing nut and the cover,

shown in Figure 14. and then remove the cartridge. Gently

tap the cartridge on a flat surface. Do not use any liquid

cleaner to wash cartridge. Do not use compressed air to re

move dirt as this may rupture the cartridge.

Examine cartridge carefully and replace it with a new one

if it is bent, crushed or if there is a noticeable loss of power.

Re-assemble cartridge and cover making sure it seats around

the back plate. Install wing nut and tighten finger tight.

AIR FILTER CARTRIDGE

WING NUT

A

FIGURE 14

IMPORTANT:

Do

not

run

engine

with

air

fiiter

removed.

BATTERY SERVICE

Check the battery electrolyte level once each month. Add

distilled water to bring the level to the bottom of the split

iring in the filler tube of each cell.

Each spring and fall remove corrosion from the terminals

and apply a light coat of grease to the terminals. Keep

battery cables securely tightened to terminals and be sure

battery is properly fastened down in battery holder at all

times. Keeping battery clean will prolong battery life.

BATTERY CABLE

POSITIVE (-H)

TERMINAL

FIGURE 15

-9-