Ariens 931015 S-18 User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Ariens dealers will provide any service which may be

required to keep the tractor operating at peak efficiency. The

tractor is equipped with the finest quality engine obtainable.

However, should servicing be required, it can be obtained

from an Ariens dealer or an authorized engine manufacturer's

service station. Consult your Ariens dealer for details.

SEAT ADJUSTMENT

The seat is adjustable forward and backward to seven

positions. To adjust seat position, grasp seat back and raise

%at. Slide the seat forward or backward as required to the

most comfortable position.

HYDROSTATIC CONTROL ADJUSTMENT

If the tractor creeps when the hydrostatic control lever is

in the neutral (N) position on the control console, make the

following adjustment;

I

The hydrostatic controls should be adjusted so the tractor

does not creep forward or backward when the control lever

in the neutral (N) slot in the control console as shown

Figure 2. In addition, the control lever should automatically

be shifted to this position from either “forward" or "reverse*'

when the neutralizer pedal is ^Hy depressed.

CAM SLOT

CAUTION:

REAR AXLE MUST BE RAISED

AND

BLOCKED

SECURELY

SO

THAT

REAR

WHEELS ARE FREE TO REVOL VE.

ì

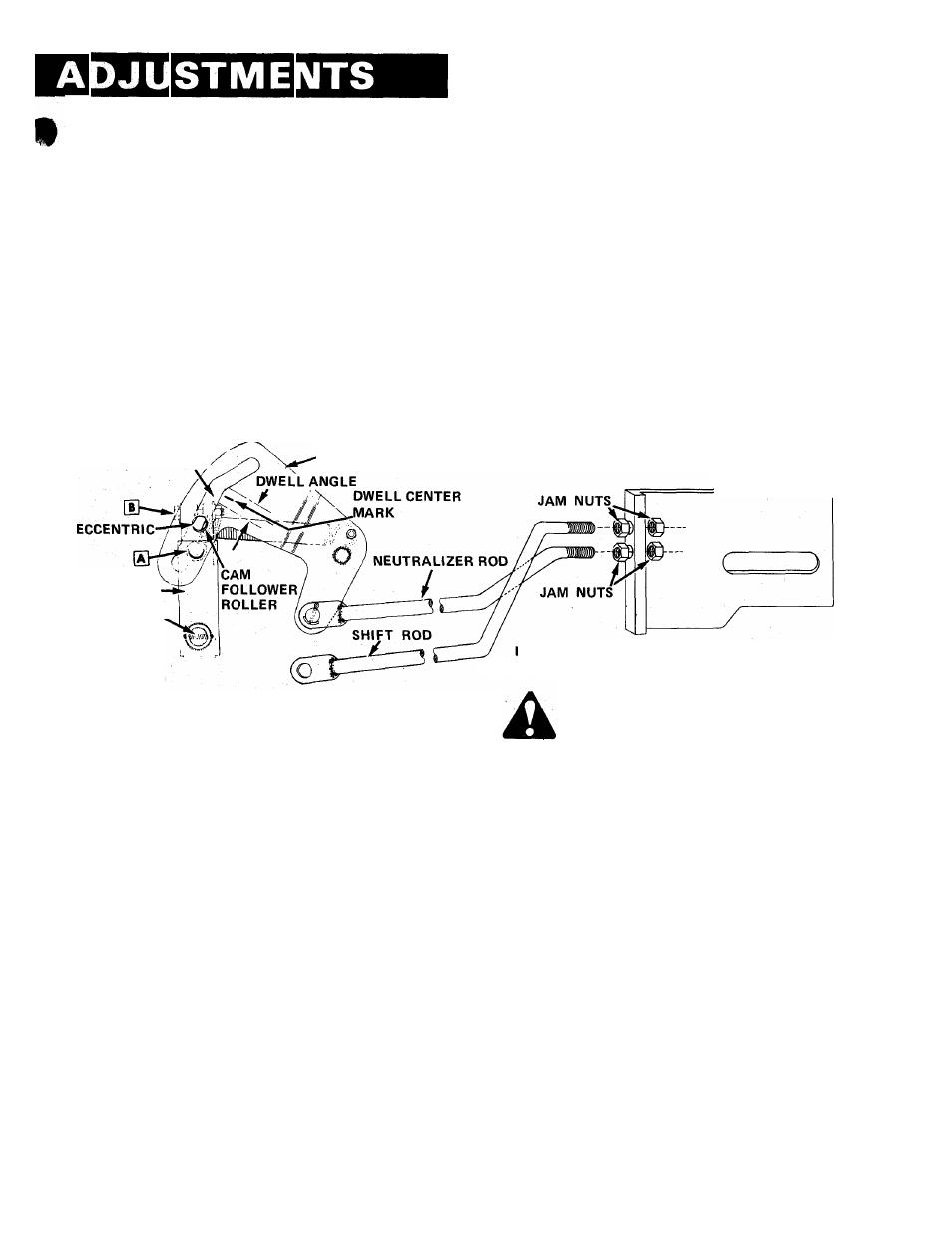

2. Loosen clamp bolt B, Figure 18 and rotate the eccentric

until the flats on the eccentric are parallel to the cam slot as

shown in Figure 18. Retighten bolt B. This will assure a

maximum fine adjustment range.

3. With the control fork. Figure 19, move the cam. Figure

18, until the cam follower roller is lined up with the cam

dwell center mark. DO NOT adjust the hydrostatic control

fork. Figure 19, if the control lever is not in the neutral slot

of the console. This is the final adjustment to be made.

4. Depress free-wheeling valves by rotating cam up. See

Figure 6.

5. Loosen pintle lever clamp bolt A, Figure 18, a sufficient

amount to allow the pintle lever to move freely. Move the

hydrostatic còntrol lever. Figure 19, in the park-start position,

start the engine and run at idle. Return the control lever to

the neutral slot in the control console.

6. Release the free-wheeling valves by rotating cam down.

Figure 6. NEUTRALIZER PLATE

PINTLE LEVER

PINTLE SHAFT

LLUSTRATED AS VIEWED

FROM RIGHT HAND SIDE OF MACHINE

FIGURE 18

1. Jack up the rear of the tractor until the drive wheels clear

the ground and BLOCK SECURELY. Wheels must be free to

revolve.

2. With the control lever in "park-start" position, raise the

rear deck. Activate seat switch to allow engine to start.

3. Start engine; place control lever in the neutral position and

increase engine speed to full throttle.

4.

Loosen clamp bolt B, Figure 18 a sufficient amount

to allow the cam follower to rotate. Turn the eccentric

"clockwise" or "counter-clockwise" as required until the

rear tractor wheels completely stop. Retighten clamp bolt B.

Check adjustment by moving the control lever to both

forward and reverse positions several times. Each time the lever

is returned to neutral, the rear wheels should stop com

pletely if they drift, re-adjust the eccentric until a true neutral

position is found.

A

CAUTION:

USE

EXTREME

CAUTION

WHEN

AD

JUSTING

THE

HYDROSTATIC

LINKAGE

WITH

THE ENGINE RUNNING DUE TO THE ROTATING

DRIVE SHAFT COUPLING AND FAN.

If a positive neutral cannot be found by adjusting the

eccentric, it will be necessary to adjust the hydrostatic

linkage using the following procedure;

1

Use steps 1 and 2 of the previous-procedure.

-11-

CAUTION:

WHEELS

MAY

TURN

WHEN

FREE

WHEELING

CAM

IS

RELEASED.

KEEP

ARMS

AND LEGS CLEAR A T A L L TIMES.

Check that the cam follower roller is lined up with cam

dwell center mark. Move the pintle arm back and forth

until wheels stop turning. Carefully tighten bolt A, Figure 18.

The neutral adjustment is extremely sensitive and this pro

cedure is a course adjustment. If, when bolt A is tightened, the

wheels still move slowly, the fine tuning will be done in step 9.

7. Loosen (4) jam nuts on neutralizing plate. Figure 18, and

depress neutralizer pedal completely. Figure 3. The cam

follower roller. Figure 18, should remain in line with the cam

dwell center mark. Snug (4) jam nuts up against neutralizer

plate. Release pedal and securely tighten jam nuts.

8. Check the hydrostatic control lever. If the neutralizer

pedal does not automatically shift the control lever to the

neutral position from either "forward" or "reverse" when

the pedal is fully depressed, loosen hydrostatic control fork

adjustment bolt D, Figure 19. Move the fork so that it aligns

with the neutral slot in the control console. Securely tighten

bolt D.

9. If the wheels still move slowly when neutralized, increase

the engine speed to full throttle. Loosen clamp bolt B,

Figure 18 and adjust the eccentric roller until the wheels

stop completely. Tighten clamp bolt B, Figure 18.