Ariens 931015 S-18 User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

REAR WHEEL TREAD ADJUSTMENT

The rear wheels are normally assembled in the narrow

tread position, shown in Figure 25. The wheels can be turned

on the hubs for a wider tread. The wide tread provides greater

stability on hillsides and on rough terrain.

Remove the wheel lug nuts, turn the wheels around with

the valve stems inward and re-assemble on the hub.

NARROW WHEEL TREAD SETTING

(23

X

10.50

X

12 TIRES SHOWN)

Æ

_•_

^

narrow

‘

s

23x 10.50 X 12 » 32'A

WIDE H

23 X 10.50 X 12 » 35V4

FIGURE 25

If Chevron tread tires are used, remove the wheel lug

nuts and re-assemble the wheels on opposite sides of the

tractor with the valve stems turned inward. I nterchanging

'the wheels is necessary to maintain proper direction of

rotation for traction tires.

HYDRAULIC LIFT OPERATION

The hydraulic control lever is located on the control

console, shown in Figure 2. It is a four position lever to per

form four functions, UP, HOLD, DOWN and FLOAT. The

normal out-of-use position is. the "HOLD" position and

the attachment will not lower or raise. When it is desired to

raise the attachment, the lever is pulled to the "UP" po

sition and the cylinder is actuated to lift the attachment.

When the lever is moved to the "DOWN" position, the oil

pressure in the cylinder is reversed and the cylinder forces

the attachment down.

When an attachment is being used which is designed to fol

low ground contours, the lever should be placed in the

"FLOAT" position.- The cylinder is then free to move as the

attachment position requires.

Figure 28 shows the components of the hydraulic lift

system. The hydrostatic transmission charge pump supplies

the oil flow from the rear axle transmission oil reservoir. Oil

flow to and from the cylinder is controlled by the valve. The

back end of the cylinder is anchored to the rear rock shaft.

The forward end of the cylinder is pinned to the lower end

of the bell crank.

When the cylinder is extended or retracted, the bell crank

pivots and raises or lowers both the front and center rock

shafts at the same time through the front and center rock

shaft linkages shown in Figure 28. The connection to the

center rock shaft is made through the slotted hole which allows

the center rock shaft to move up and down, allowing the

mower to float independent of the flotation provision in

the hydraulic system.

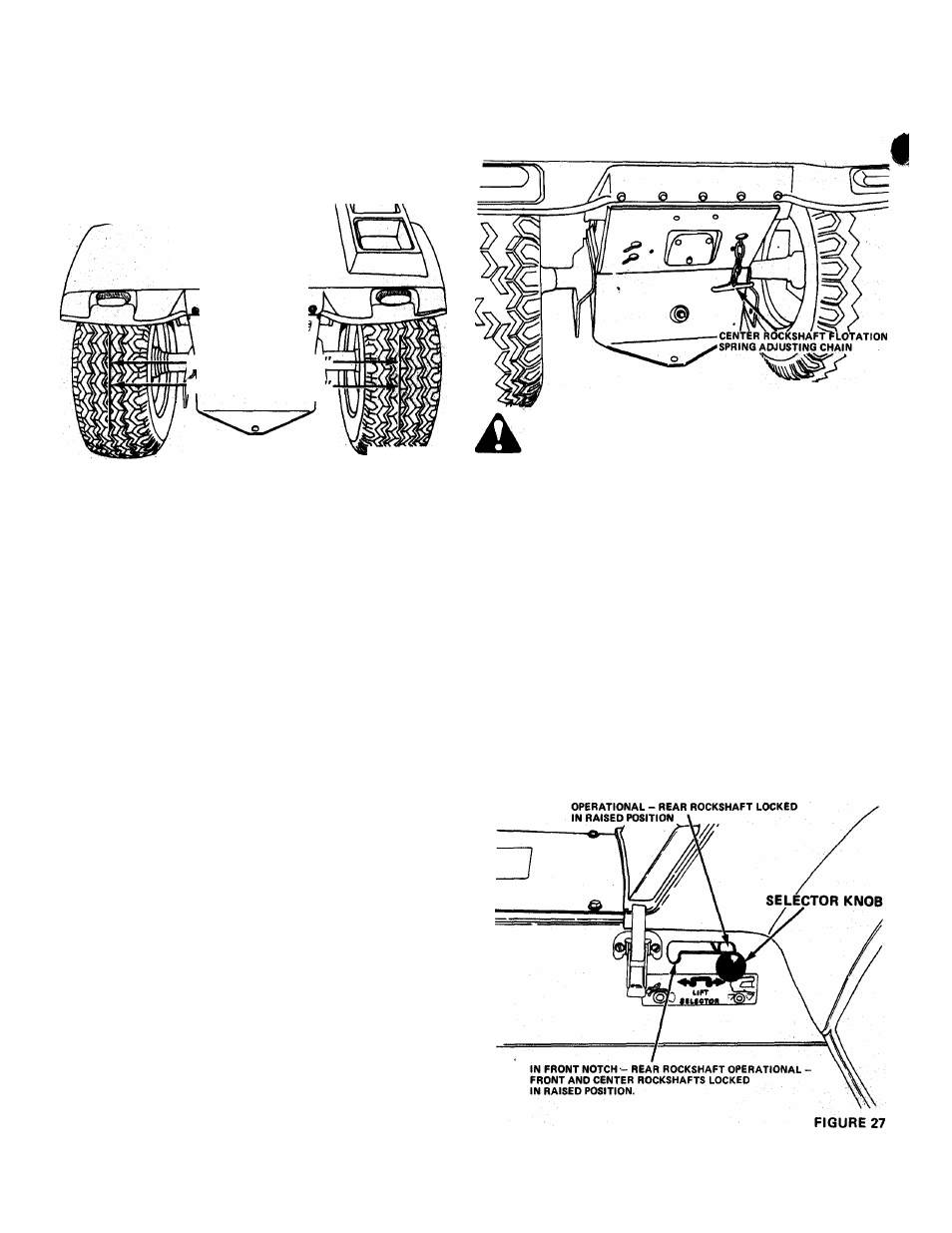

The center rock shaft flotation spring provides mower

flotation. The tension on the spring can be increased by pulling

the chain shown in Figure 26 and latching a chain link in the

notch in the back of the tractor frame. This spring should

always be in use when the mower pan is used.

FIGURE 26

CAUTION - WHEN ADJUSTING CHAIN TENSION ALWAYS GRASP

CHAIN HANDLE FIRMLY (NOT THE CHAIN) AS CONSIDERABLE TENSION

IS ON THE CHAIN AND INJURY TO THE HANDS COULD RESULT.

HYDRAULIC LIFT REAR ROCK SHAFT

The tractor comes with a lift selector device so that

the front and center rock shafts can be operated in

dependently of the rear rock shaft while utilizing only one

hydraulic cylinder. The alternately latched, split lift linkage

system holds the front and center rook shafts in their raised

positions while the rear rock shaft is operated by the cylinder

or vice versa. This allows a rear mounted attachment to be

used without removing the front pr center mounted attach

ments and vice versa.

€

To make the rear rock shaft operational, move the hy

draulic control lever to the "UP" position and hold it there

uritil the cylinder is fully extended. Place the selector knob in

the front notch (Figure 27).

To make the front and center rock shafts operational,

move the hydraulic control lever to the "UP" position and

hold it there until the cylinder is fully extended. Place the

selector knob in the rear notch as shown in Figure 27.

IN REAR NOTCH - FRONT AND CENTER ROCKSHAFTS

- 1 4 -