Ariens 931015 S-18 User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

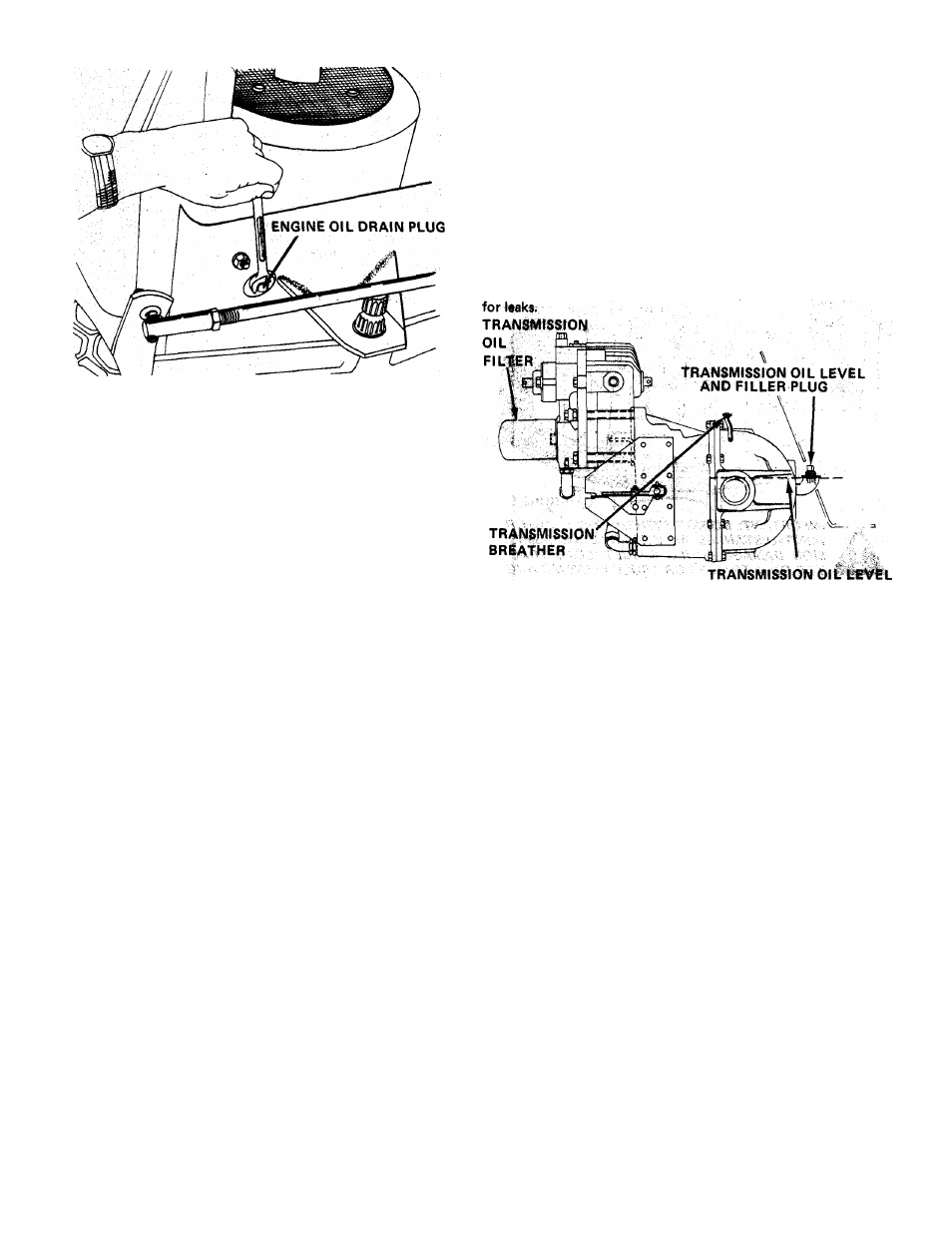

NOTE: Bottom of engine shown.

FIGURE 10

Replace drain plug. Remove dip stick and refill crankcase

with 4 U.S. pints of oii. Check oil pn the dip stick to see that

the oil level is at the fuli (F) mark. Do notoverfiil.

TRANSMISSION OIL GRADE AND VISCOSITY

Ariens Gard-N-Yard lOW-30 or an equivalent detergent

type motor oil meeting the requirements of the American

Petroleum Institute (A.P.i.) Service Classification SE should

be used. Oil viscbsity (weight) should be SAE 10W-30 and is

recommended for year-round use.

TRANSMISSION OIL LEVEL

The hydrostatic transmission, differential and hydraulic

lift system all operate from a common oil reservoir. Note that

the rear end is the oil reservoir. The oil level in the reservoir

should be checked every 25 hours of operation or

monthly.

A

CAUTION: Proper oil level is essential for proper

operation and protection against severe damage to

the transmission as well as dynamic braking.

Use the following procedure to check the transmission

oil level:

1. Drive tractor onto level ground.

2, On tractors with hydraulic lift systems, move hydraulic

control lever to the "DOWN" position until the lift cylinder

is fully retracted.

3. Move control lever to park start, keeping engine at fast

idle.

4. Wipe dirt from around the oil level and filler plug. See

Figure?.

5. Remove plug. Oil level should be to the top of the pipe

elbow at the filler plug, see Figure 11.

6. If necessary, use a small funnel to add sufficient SAE

10W-30 with SE classification motor oil to bring the oil up

to tVie proper level. Replace plug.

; Be very careful to prevent dirt and foreign materials from

entering the oil reservoir when checking or adding oil.

A

CHANGE TRANSMISSION OIL FILTER

When the tractor is new, change the filter after the

first five (5) hours of operation.

Thereafter, the filter should be changed every 100 hours

or annually, whichever comes first. It is not necessary to

change the transmission oil.

Use the following procedure to change the transmisSiOft

oil filter.

1. Drive the tractor onto level ground. Place a container

under the filter to catch oil spillage as filter is removed.

2. Unscrew and discard oil filter. Use an oil filter removal

tool if necessary.

i

3. Moisten the rubber gasket with oil and install the filter.

4. Siart engine and cycle the hydraulic lift until it operates

smoothly. This bleeds the air out of the transmission. Check

FIGURE 11

5. M^va contrtii lever to park start* keeping engine at faSt

i d l e i i '

* i ' -

6. Wipe dirt from around the oil level and filler plugs. See

Figure 8. Remove plug.

7. Add sufficient SAE 10W-30 motor oil so that the oil fills

the elbow. Install the filler plug.

Be very careful to prevent dirt and foreign materials from

entering the reservoir or oil filter when changing the oil and

filter.

Be sure breather is not clogged. Wipe clean with a rag and

solvent.See Figure 11.

GREASE STEERING SYSTEM

Under normal conditions the steering system should be

lubricated every 50 hours of operation or quarterly whichever

occurs first. The following list of grease fittings are identified

in Figure 12. Wipe each fitting clean before and after

lubrication! Use a good grade of general purpose grease such

as Ariens Multi-Purpose grease.

Rotate steering wheel clockwise until the spindle arm con

tacts the axle stop and fill gearbox until grease is forced out

around the cam follower adjusting screw.

W Steering gearbox.

W Left king pin.

® Front L.H. Wheel.

^ Axle pivot.

Right king pin.

Front R.H. Wheel.

i

-8-