Ariens 931015 S-18 User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

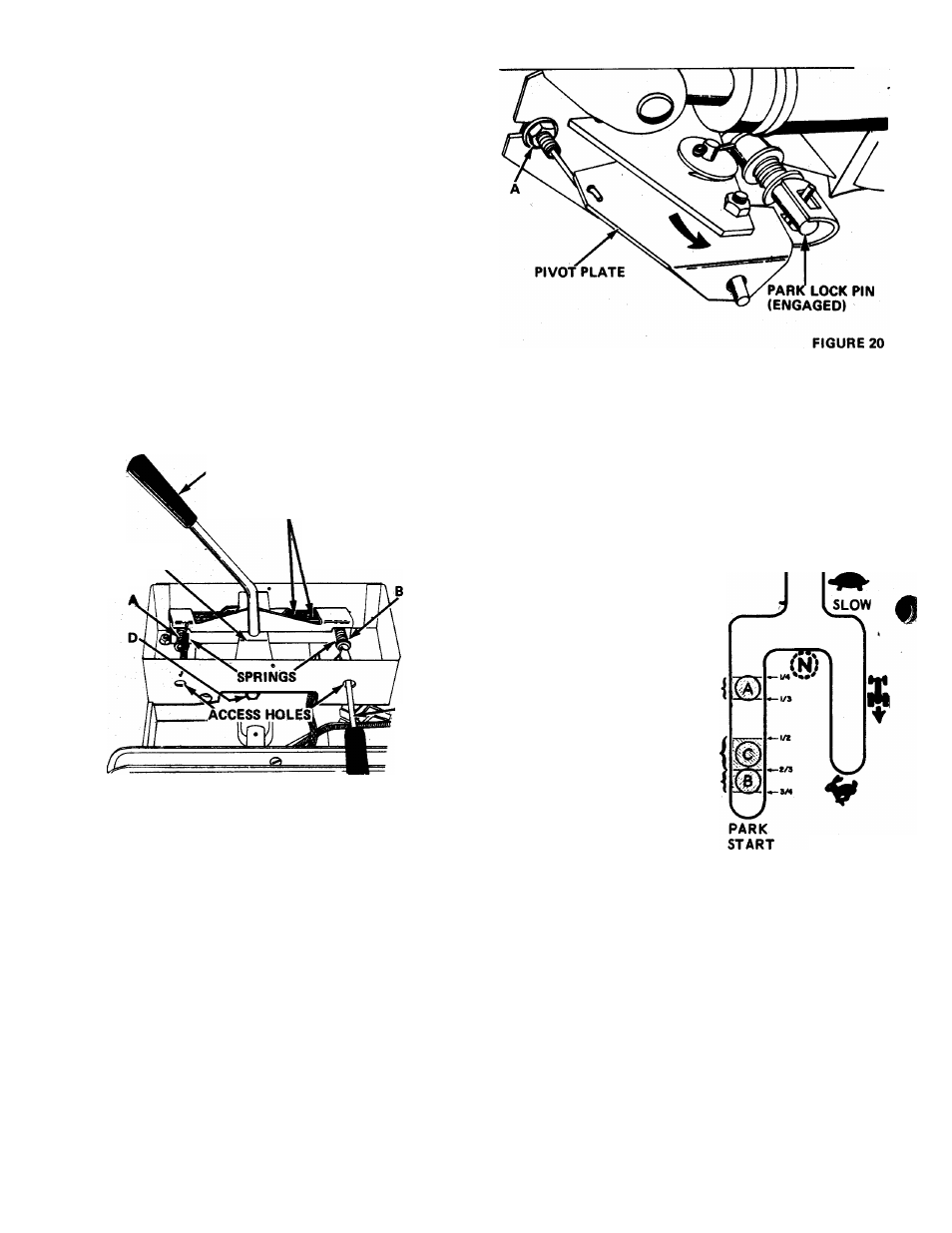

CONTROL LEVER FRICTION ADJUSTMENT

The hydrostatic friction plates, shown in Figure 19, must

be adjusted so the control lever moves through the "forward"

and "reverse" modes with a minimum of force. However,

there must be sufficient spring pressure on the friction

plates so that, under normal operating conditions, the control

lever will remain at any selected setting.

If the tractor has a tendency to slow down or speed up

without touching the control lever, it will be necessary to in

crease the spring pressure on the friction plates by tightening

the screws at A and B, Figure 19. Access to these screws can

be gained by raising the rear deck of the tractor and inserting

a screw driver through the access holes as shown.

If the tractor has a tendency to speed up, tighten screw A

slightly more than screw B.

i

If the tractor has a tendency to slow down, tighten screw

B slightly more than screw A.

NOTE:

The

control

console,

see

Figure

19,

has

been

removed for clarity only.

.HANDCONTROL LEVER

When the mechanism is properly adjusted, the park-lock pin

will engage the teeth of the reduction gear when the

control lever reaches Point B, Figure 21, and the pin will

be completely disengaged at Point A.

FRICTION PLATES

HYDROSTATIC

CONTROL

FORK

CONTROL CONSOLE -

REMOVED FOR CLARITY

Adjustment is made by loosening

nuts A, Figure 20, and moving the

cable housing "in" or "out" until

the over-center latch actuates when

the control lever reaches Point C,

Figure 21, as the lever is moved

from the front of the slot, rear

ward into the park-start position.

Moving the cable housing "in" to

ward the tractor causes the park-

lock pin to engage later. Moving it

"out" away from the tractor causes

the pin to engage earlier in

the reduction gear.

FAST

4

X

PARK LOCK DISENGAGES

SCREWDRIVER

OVERCENTER LATCH ACTUATES

FIGURE 19

PARK LOCK MAINTENANCE AND ADJUSTMENT

PARK LOCK ENGAGES

When the hydrostatic control lever is placed in the "park-

start" position, the cable shown in Figure 20 is pushed out of

the cable housing causing the pivot plate to rotate in the di

rection of the arrow. This results in the park-lock pin engaging

in a reduction gear in the differential housing which locks the

rear wheels. When the control lever is moved forward, the

pivot plate rotates opposite to the direction of the arrow

shown in Figure 20 and the park-lock pin disengages from the

reduction gear thus unlocking the rear wheels.

FIGURE 21

PARK LOCK BRAKE ADJUSTMENT

The park lock brake must be adjusted to hold the control

lever at the rear of the "park-start" slot in the console. Other

wise, while starting the engine, the control lever will need to

be held back to fully depress the safety switch located under

the console cover.

The park-lock mechanism should be kept clean of any dirt

or grass build-up and the moving parts should be oiled

occasionally to assure that the park-lock functions properly.

The "park-lock" brake is adjusted by tightening or loosen

ing nut A, Figure 20;

FRONT WHEEL TOE-IN ADJUSTMENT

The park-lock mechanism is properly adjusted when the

over-center latch pin, Figure 20 actuates at Point C, Figure

2fl (approximately 1/2 to 2/3 the length of the slot on the

console cover), as the control lever is moved from the front

of the slot back into the park-start position. A distinct

"click" can be heard when the over-center latch actuates.

Proper toe-in of the front wheels is necessary to assure

proper steering and to reduce tire wear. The proper amount

of toe-in is when the front of the wheels are 1/16" to 1/8"

closer together than the rear of the wheels, measured at the

horizontal centerline of the rim flange.

-12-