Service and adjustments, Engine, Note – Ariens PRM-10000 User Manual

Page 39: Attaching, Operation, Runners, Scraper blade, Shear bolt replacement

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SERVICE AND ADJUSTMENTS

1. ENGINE

Refer to engine instruction book and nameplate

on engine for maintenance instructions. If repairs or

service are needed for engine, see an Ariens dealer

or nearest authorized engine service station.

NOTE

Maximum engine RPM for all engines

used on equipment in this manual is

3600 RPM.

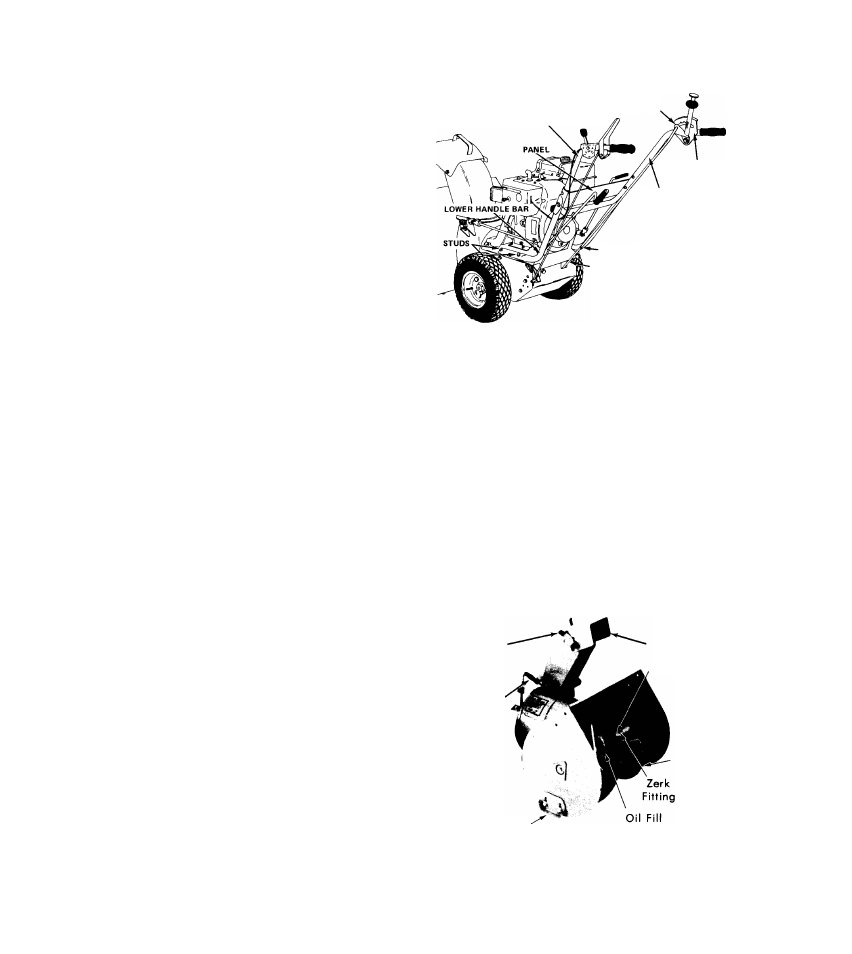

2. ATTACHING

a. Sno-Thro Attachment.

(1) Hook the notches in the lower portion of

the Sno-Thro Attachment frame over the rod

passing through the forward section of the tractor

frame.

(2) Tip the two sections together, being sure

the jaw clutch on the Sno-Thro Attachment is in

the OUT position (counterclockwise).

(3) Insert and tighten the two 3/8-inch whiz-

lock screws through the top of the tractor frame

and into the Sno-Thro Attachment.

b. Chute Control Rod.

(1) Fasten the chute control crank to the

tractor handle bar with the hardware provided.

Position the worm gear so that it meshes properly

with the chute. Fasten securely.

3. OPERATION

a. To start the Sno-Thro Attachment, start the

engine, placing the Sno-Thro clutch in the IN position

(clockwise) and engage the engine clutch on the

tractor.

b. To stop the Sno-Thro Attachment, disengage

the engine clutch on the tractor and place the

Sno-Thro clutch in the OUT position.

c. The tractor may be used to move the unit with

the Sno-Thro Attachment stopped by engaging the

tractor clutch and leaving the Sno-Thro clutch in the

OUT position.

4. RUNNERS

a. An adjustable runner is provided on each side

of the blower housing (Figure 2). Raising or lowering

these runners controls the distance the scraper blade

is held above the surface being cleared. Adjustment

is accomplished by loosening the two nuts on each of

the runners to the desired position and retightening

the nuts. When blowing snow off concrete or other

hard surfaces, these runners should be adjusted so

that they are approximately 1/8-inch below the

scraper blade. When blawing snow off gravel

driveways or other gravel areas, adjust the runners so

that they are 1-1/4-inches below the scraper blade.

b. In wet snow which packs easily, it may be

WASHER AND COTTER PIN ,

UPPER HANDLE BAR

SHIFT

CONTROL

UPPER SHIFT ROD

LOCKNUT

LOWER SHIFT ROD

FIGURE 1

necessary to remove the runners or turn them upside

down so the scraper blade will scrape clean.

5. SCRAPER BLADE

A scraper blade (Figure 2) is provided along the

bottom

edge

of

the

blower

housing.

During

operation, this blade runs along the surface being

cleared, directing the snow into the rotor and insuring

a clean surface. After considerable usage, this blade

may wear and require replacement. The blade can be

replaced by removing the carriage bolts holding it to

the housing.

6. SHEAR BOLT REPLACEMENT

Occasionally a small object may enter the rotor

and become jammed in the blades. When this occurs,

the shear bolts, located on the shaft on which the

rotor is mounted, will break and allow the rotor to

turn freely on the shaft. Before blowing can be

continued, this shear bolt must be replaced. See

Figure 2. USE ONLY ARIENS SHEAR BOLTS. USE

Wing Nut

Sno-Thro

Clutch

Adjustable

Runner

Deflector

Shear Bolt

Scraper

Blade

Page 39