Buttonholes – SINGER W1213 User Manual

Page 24

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

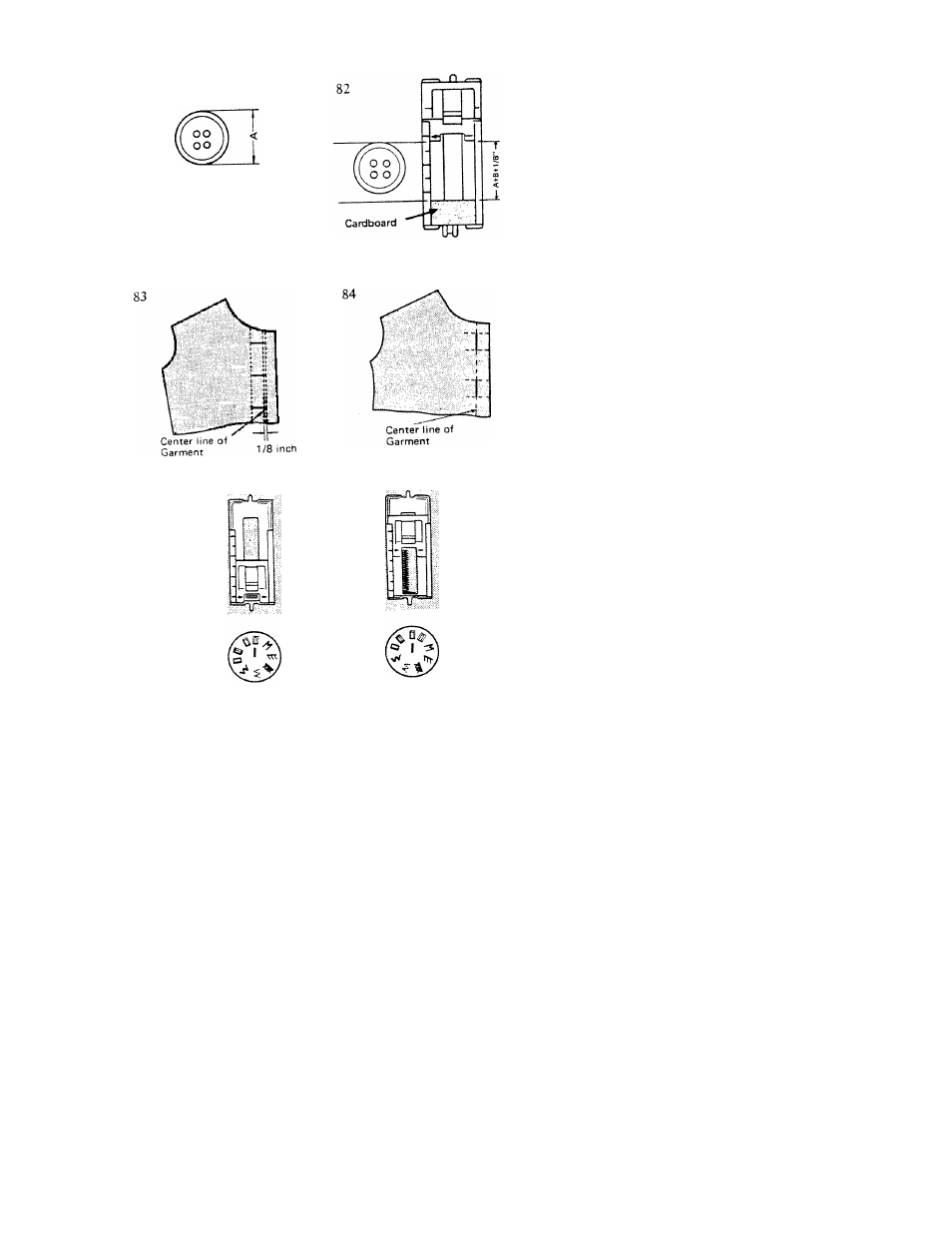

81

85-1

Step 1

Step 2

Pattern -

U

l

L _

Length — '/4

—/'2

Width — 3 — 5

Needle Position - M

Feed Dog - High

Pressure - 5

Foot - Buttonhole

Built-in Buttonhole

This

buttonhole

eliminates

the

need

or

pivoting the fabric. It is used most often on

light and medium woven fabrics.

1

Set pattern selector dial for the first

’ buttonhole position. Lower needle into

the mark at the end of buttonhole. Lower

presser foot and take a few stitches to

bartack. (Fig.85-1 Step 1)

5 With needle out of the fabric, turn pattern

“■

selector

dial

to

second

picture.

Sew

up

left

side

of

buttonhole

until

the

white

nylon slide runs into the back of lip of

the foot. At this position, the machine is

feeding in reverse. (Fig.85-1 Step 2)

IX.

Buttonholes

Various

fabrics

require

various

methods

of

sewing

buttonholes.

Four

different

methods

are

given

below,

with

suggested

uses.

If

you

are in doubt as to which method is best for

vour fabric, test the methods in question and

choose

the

best

according

to

the

finished

appearance.

,

preparation

For

the

best

results,

a

good

quality

mercerized

cotton

thread

should

be

used.

Polyester

threads

often

result

in

puckered

or

heavy

unattractive

buttonholes.

The

tiner

your

fabric

is,

the

finer

your

cotton

thread

should be.

An

interfacing

should

be

used

under

the

buttonholes

to

give

body,

to

strengthen,

and

to help them withstand wear.

To

establish

the

correct

length

of

the

buttonhole,

add

the

diameter

of

the

button

(A) plus the thickness of the button (B), plus

l/g’inch for the bartacks. (Fig. 81) The length

may be marked on the garment with a basting

stitch,

tailor’s

chalk,

or

transparent

tape.

Another

way

to

make

sure

that

all

button

holes will be the same size is to cut a piece

of

cardboard

as

wide

as

the

buttonhole

foot

and

long

enough

to

make

the

distance

between

the

toe

of

the

white

slide

and

the

cardboard

the

size

buttonhole

needed.

(Fig.

82)

This

method

works

for

buttonholes

up

to

1

1/8

inches

long.

Horizontal

buttonholes

should extend 1/8 inch beyond the center line

of

the

garment.

(Fig.

83)

Vertical

buttonholes

are

placed

so

that

the

cutting

space

of

the

buttonhole

is

directly

on

the

center

line.

(Fig. 84)

Always

make a practice buttonhole on a scrap

of

the

garment

fabric

before

making

any

buttonholes

on

your

garment.

On

your

test

sample,

duplicate

the

thicknesses

found

in

the

garment

and

be

sure

to

include

the

interfacing.

The

test

sample

should

help

determine the length needed for the button to

pass through the hole easily, as well as the

stitch

length

needed

for

the

particular

fabric.

As with the satin stitch, the stitches should be

close together, but not so close that they pile

up.

Be sure to use the buttonhole foot.

01