SINGER W1213 User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

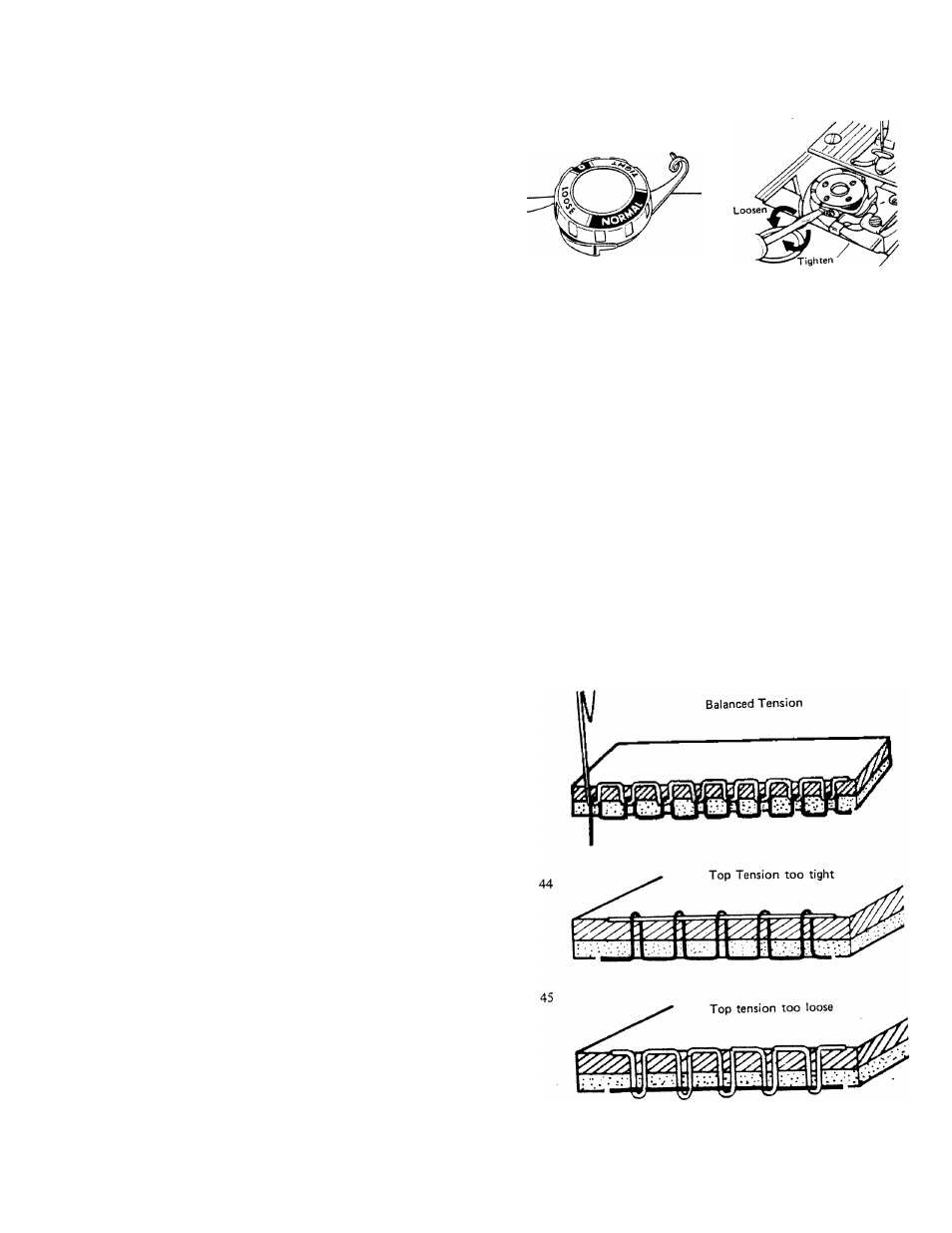

Tension Dial

The

top

tension

(Fig.41)

consists

of

discs

between

which

the

thread

passes.

The

descriptive

tension

dial

regulates

how

tightly

the

thread

is

being

held.

When

necessary,

adjust the top tension in relation to the red

line,

turning

toward

“loose”

or

“tight”

as

needed. The top tension is engaged only when

the presser foot is down for sewing.

The

bobbin

thread

tension

is

controlled

by

the left small screw on the front edge of the

bobbin

case.

(Fig.42)

This

screw

may

be

turned with the small screw driver resting in

the notch of the slide plate. Turn to the right

to tighten and to the left to loosen.

41

42

Adjusting the Tension

The

tensions

may

have

to

be

adjusted

for

certain fabrics.

Before adjusting your tension

make

sure

that

the

machine

is

properly

threaded

with

identical

thread

on

both

top and bobbin.

Use a new needle the correct

size for the thread and fabric being sewn. (See

chart page 8.)

It is best to test the tension on a scrap of the

fabric you are using for construction.

Always

use a double thickness and always sew on the

bias when testing tension.

The

tensions

are

correct

when

the

upper

thread

and

lower

thread

interlock

between

the two layers of fabric with the loops not

showing on top or bottom. (Fig. 43)

Adjust as follows;

1

.

2

.

3.

If

the

seam

is

puckered

both

top

and

bobbin

tensions

are

too

tight.

Loosen

both tensions slightly. (Fig.43)

If

top

thread

lays

on

the

fabric

with

bottom

thread

looping

over

it,

the

top

tension is too tight. (Fig. 44) Loosen the

top tension slightly.

If the bottom thread lays on the fabric

with the upper thread looping over U, top

tension

is

too

loose.

(Fig.

45)

Tighten

top tension slightly.

Pattern - M

Length - 2-3

Width - 0

Needle Position - M

Feed Dog - High

Pressure - 5

Foot - All Purpose

43