SINGER 114W110 User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

DESCRIPTION

Machine 114 w 110 is designed for sewing braid on waists,

cloaks, suits, dresses, skirts, robes, opera wraps, uniforms,

millinery goods and a great variety of other articles such as

curtains, table covers, mantel scarfs, etc., all of which are made

very attractive by the ornamental designs produced by the

machine. Fabrics, including fine chiffon, georgette, china silk,

net and similar sheer materials, also the heavier fabrics such as

broad cloth, velvet, etc., arc stitched with ecjual satisfaction by

the machine.

The braid can be sewn “flat on,” or it can be sewn “edge on”

for what is known as “standing” braid. When the machine is

u.scd for sewing the braid “flat on,” the invisible lock stitch is

made, the stitches being placed in the centre on the underside of

the braid. When the braid is sewn “edge on,” one of the edges of

the braid stands upward, producing artistic effects different from

those obtained when the braid is stitched on flat. (See pages 18

and 20).

The braid is taken from a s])ool located at the top of the

machine, and passed down through a tube to a suitable guide

which conducts it to the needle in the desired position for stitching.

Braid guides can be furnished for various descriptions of braids as

shown on page 15, and samples of the braid to be used should

accompany orders for guides.

The usual method for sewing on the braid is to follow a

pattern that has been stamped or traced upon the fabric. With a

little practice the operator can produce ornamental designs with

out the aid of patterns.

The machine has one needle and one oscillating shuttle.

Speed

The speed of the machine is limited only by the skill of the

operator. The machine should be started at a speed of about 600

stitches per minute and this speed can be increased when the

operator becomes proficient and the nature of the work permits.

When the machine is in operation the balance wheel should always

turn over from the operator.

When the machine is received from the factory it should be

thoroughly cleaned and oiled.

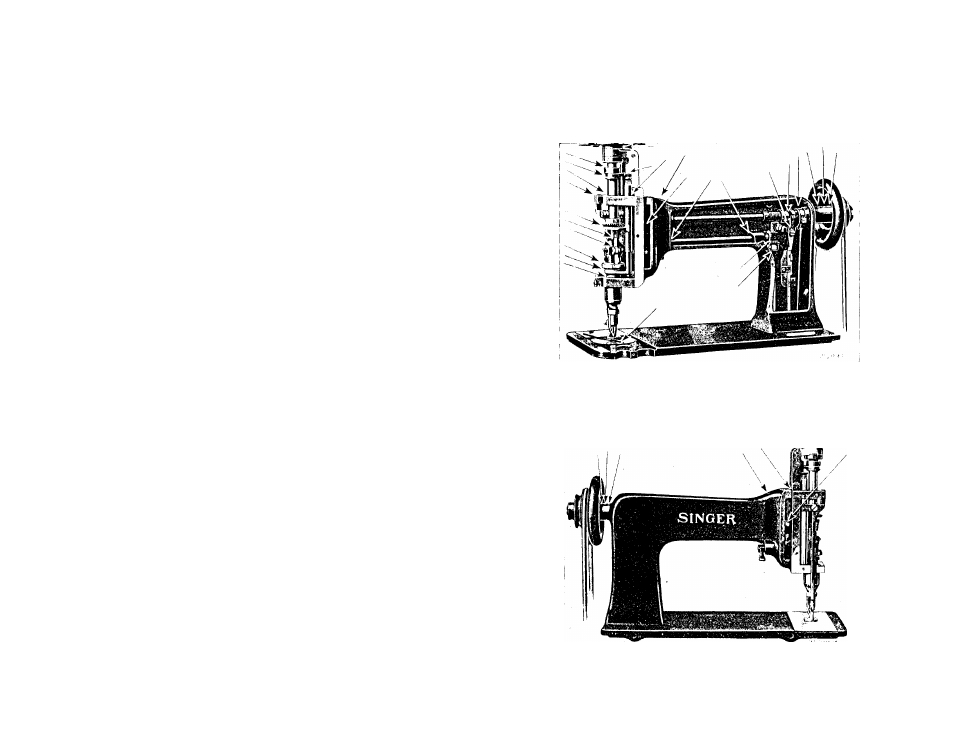

To Oil the Machine

F l ( ! .

2

.

O i r . I M i I ’ O I N ' I S A T T M K l ' ' l U ) N T o e T H I O

i

M

a c h i n k

To clean the machine, use a little kerosene at the oiling

points shown in Figs. 2, 8, 4 and 5, run th(> machiiu' ra])idly for

one minute then wipe clean.

K

k

; . .'i. O i L i N i i I ’ o i N T s A T T i l l - : H

a c k

o k

■ n i i o M

a c h i n e