Sears 247.8867 User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

The Maintenance Check List is supplied to assist the

operator in proper maintenance of the snow thrower.

This is only a check list; instructions lor adjustments

will be found in the Adjustments/Repairs section of this

manual.

Some adjustments will need to be made periodically

to properly maintain your snow thrower.

All adjustments in Adjustments/Repairs section of this

manual should be checked at least once a season. The

following should be performed more than once each

season.

All Bolls and Nuts—Should be checked often to make

certain they are tight, preferably after each use.

Engine and Snow Thrower—Lubricate as instructed

in the following section.

LUBRICATION

Engine Lubrication—Check Oil Level before starting

engine and every 5 hours of operation. Oil level must

be maintained between the ‘‘Full” and “Add” marks

on dipstick. Referto “To Service Engine” instructions

on page 8.

Change Oil after first 2 hours of operation and every

25 hours thereafter. Change at least once a year if the

snow thrower is not used for 25 hours.

To drain oil, position snow thrower so the oil drain plug

is the lowest point on the engine. Remove oil drain plug

and oil fill cap . See figure 17. Drain oil into a suitable

container. Oil will drain more freely when warm.

Replace oil drain plug and tighten securely. Refill

crankcase with SAE 10W30 motor oil. SAE 5W30 motor

oil may be substituted when temperature is consistently

20®F. or lower.

Oil Cap/>^

Dipstick

Drain-^-

Plug

figure

17,

AZOTE; 0/7 teve/

must be between

full and add mark

Drive Chain—Using engine oil, lubricate the drive

chain after each 10 hours of operation and before

storage as follows.

1. Make certain the speed select lever is in Neutral.

Tip the snow thrower forward so it rests on the

housing.

2. There are two openings in the bottom cover. The

drive chain can be oiled through the left opening.

Turn the left wheel by hand to rotate the chain so

the entire chain can be lubricated.

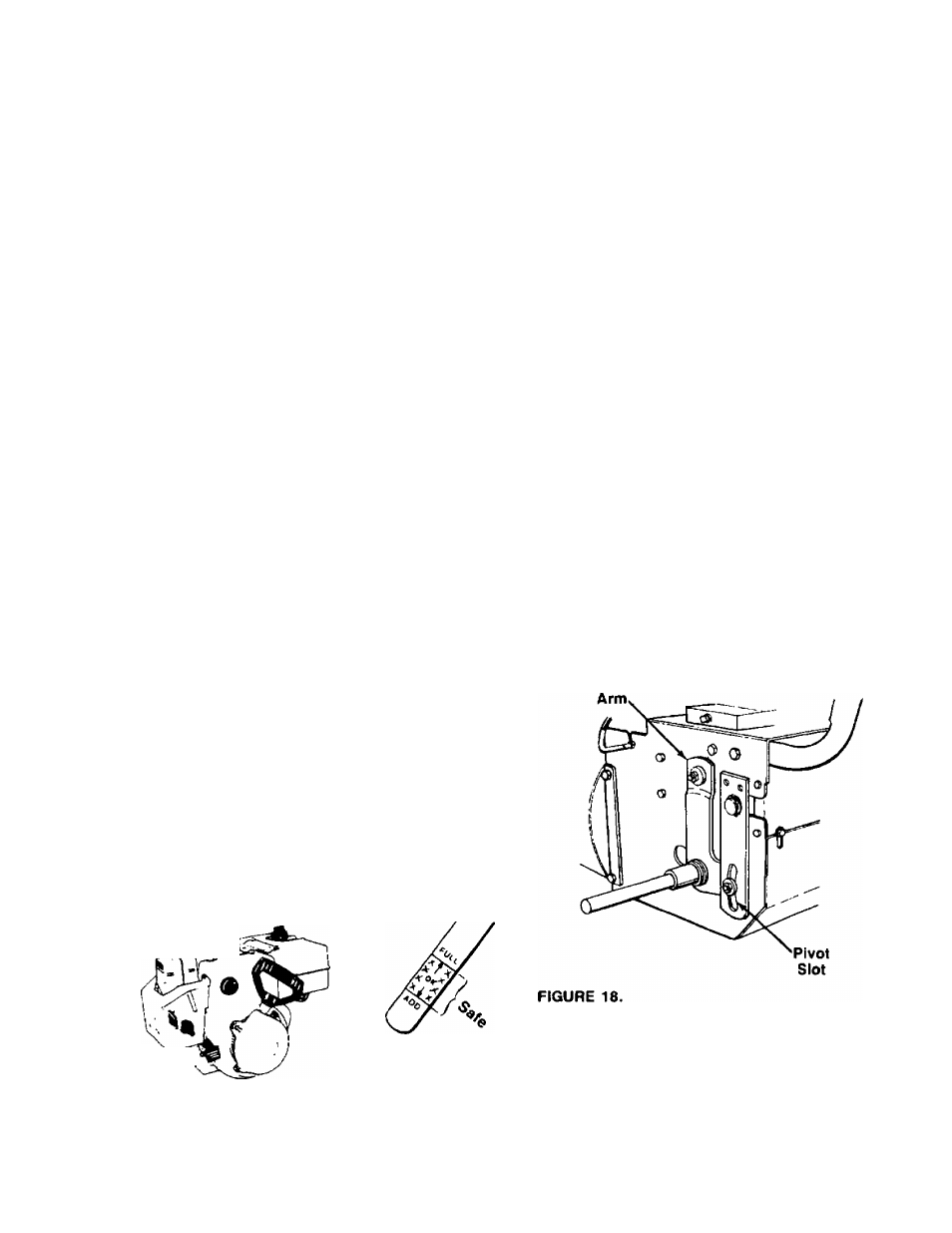

Pivot Points—Grease pivot slots and pivot arms (both

sides of unit) before each season, before storage and

after each 10 hours of operation, using a multi-purpose

automotive grease. See figure 18. After applying

grease, work the weight transfer lever back and forth

to distribute the grease.

NOTE

Rgure 18 is shown with the wheel removed

for clarity only. It is not necessary to

remove the wheel to lubricate the pivot

slots and pivot arms.

Pivot

Transmission—The transmission is lubricated at the

factory and does require not additional lubrication. If

the transmission is disassembled for service, lubricate

with 12 ounces of Benalene grease. Order pari number

737-0223 (10 ounce tube) through your nearest Sears

Service Center.

11