Battery, Engine, Lubrication – Sears 917.251551 User Manual

Page 18: Customer responsieilîties

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CUSTOMER RESPONSieiLÎTIES

BATTERY

Your tractor has a battery charging system which is suffi

cient for normal use. However, periodic charging of the

battery with an automotive charger will extend its life.

•

Keep battery and terminals dean.

« Keep battery bolts tight.

» Keep small vent holes open,

« Rechargeât 6-10 amperes for 1 hour,

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battery and terminals can cause

the battery to "leak” power.

» Remove terminal guard.

» Disconnect BLACK battery cable first then RED bat

tery cable and remove battery from tractor.

•

Rinse the battery with plain water and dry.

•

Clean terminals and battery cable ends with wire brush

until bright.

" Coat terminals with grease or petroleum jelly.

•

Reinstall battery (See "CONNECT BATTERY" in the

Assembly section of this manual).

ENGINE

LUBRICATION

Only use high quality detergent oil rated with API service

classification SF or SG. Select the oil’s SAE viscosity g rade

according to your expected operating temperature.

NOTE: Although multi-viscosity oils (5W30,10W30 etc.)

improve starting in cold weather, these multi-viscosity oils

will result in increased oil consumption when used above

32° F. Check your engine oil level more frequently to avoid

possible engine damage from running low on oil.

Change the oil after the first two hours of operation and

every 50 hours thereafter or at least once a year if the

tractor is not used for 50 hours in one year.

Check the crankcase oil level before starting the engine

and after each eight (8) hours of operation. Tighten oil fill

cap/dipstick securely each time you check the oil level.

SAE VISCOSITY GRADES

1 Î 1 1

■

■

°F

*20“

0“

30“ 32“ 40” 60"

80“ 100"

°C .30"

20" -W 0" 10" 20“ 30° 40"

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE '

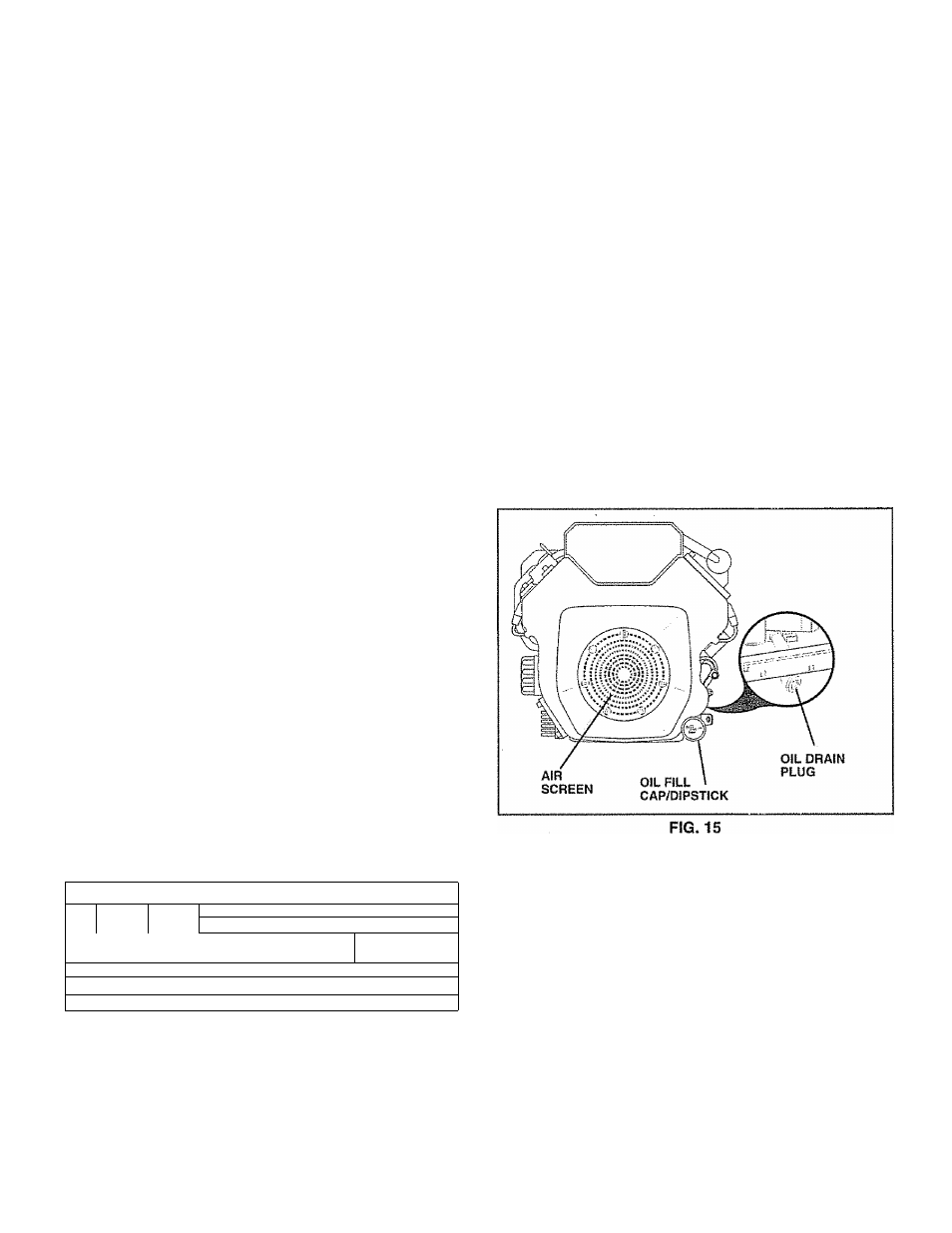

TO CHANGE ENGINE OIL (See Figs. 14 and 15)

Determine temperature range expected before oil change.

All oil must meet API service classification SF or SG.

Be sure tractor is on level surface,

Oil will drain more freely when warm.

Catch oil in a suitable container.

Remove oil fill cap/dipstick. Be careful not to allow dirt

to enter the engine when changing oil.

Remove drain plug.

After oil has drained completely, replace oH drain plug

and tighten securely.

Refill engine with oil through oil fill dipstick tube. Pour

slowly. Do not overfill. For approximate capacity see

“PRODUCT SPECIFICATIONS" on page 3 of this

manual.

Use gauge on oil fill cap/dipstick for checking level.

Insert dipstick into the tube and rest the oil fill cap on the

tube. Do not thread the cap onto the tube when taking

reading. Keep oil at "FULL" line on dipstick. Tighten

cap onto the tube securely when finished.

FIG. 14

18