To replace mower blade drive belt (see fig. 28), To adjust attachment clutch (see fig. 29), To adjust brake (see fig. 30) – Sears 917.25597 User Manual

Page 21: Service, Adjustments

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SERVICE

AND

ADJUSTMENTS

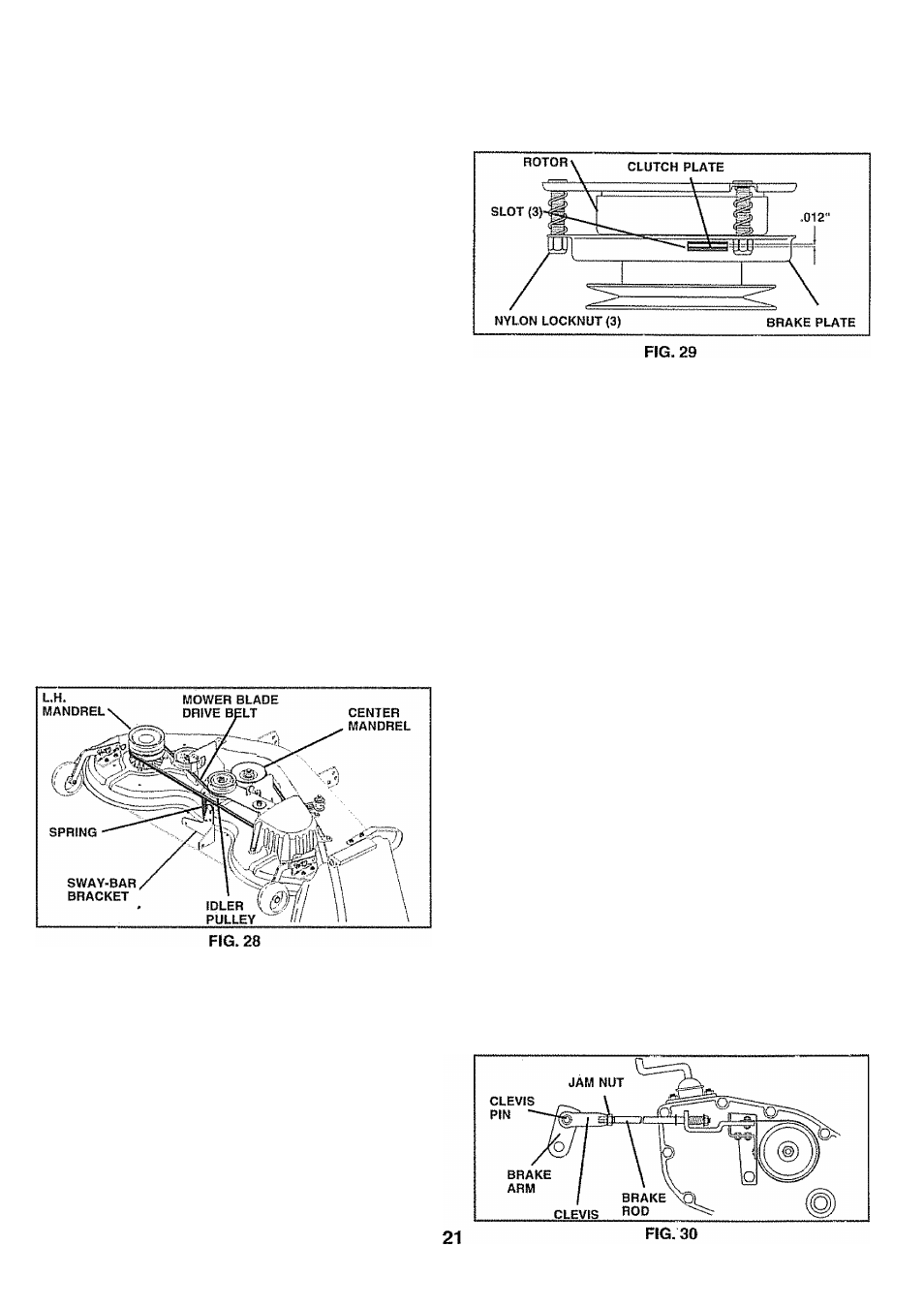

TO REPLACE MOWER BLADE DRIVE BELT

(See Fig. 28)

Park the tractor on level surface,, Engage parking brake.

Remove mowerdrive belt (See ‘TO REPUCE MOWER

DRIVE BELT” in this section of this manual).

Remove mower (See “TO REMOVE MOWER” in this

section of this manual).

Remove four screws from R.H. mandrel cover and

remove cover. Unhook spring from bolt on mower

housing.

Carefully roll belt off R.H. mandrel.

Remove belt from center mandrel, idler pulley, and L.H.

mandrel.

Remove any dirt or grass which may have accumu

lated around mandrels and entire upper deck surface.

Check secondary idler arm and idler to see that they

rotate freely.

Be sure spring is hooked in secondary idler arm and

sway-bar bracket.

Install new belt in lower groove of L.H, mandrel, idler,

and center mandrel as shown.

Roll belt over R.H. mandrel. Make sure belt is in all

grooves properly.

Reconnect spring to bolt in mower housing and rein

stall R.H. mandrel cover.

Reinstall mowerto tractor (See “TO INST ALL MOWER”

in the Assembly section of this manual).

Reassemble mower drive belt (See “TO REPLACE

MOWER DRIVE BELT’ in this section of this manual).

TO ADJUST ATTACHMENT CLUTCH

(See Fig. 29)

The electric clutch should provide years of service. The

clutch has a built-in brake that stops the pulley within 5

seconds. Eventually, the internal brake will wear which

may cause the mower blades to not engage, or. to not stop

as required. Adjustments should be made by an authorized

service technician.

•> Make sure attachment clutch and ignition switches are

in "OFF’ position,

• Adjust the three nylon locknuts until space between

clutch plate and rotor measures .012“ at all three slot

locations cut inside of brake plate.

NOTE:

After installing a new electric clutch, run tractor at

full throttle and engage and disengage electric clutch 10

cycles to wear in clutch plate.

TO ADJUST BRAKE (See Fig. 30)

Your tractor is equipped with an adjustable brake system

which is mounted on the left side of the transaxle,

If tractor requires more than six (6) feet stopping distance

at high speed in highest gear, then brake must be adjusted.

IMPORTANT: DO NOT OVER TIGHTEN BRAKE. WHEN

DEPRESSING CLUTCH BRAKE PEDAL, THE MOTION DRIVE

BELT MUST STOP MOVING (DECLUTCH FROM ENGINE

PULLEY)

BEFORE

BRAKE

ENGAGES.

IMPROPER

ADJUSTMENTWiLLCAUSE HARD SHIFTING AND EXCESSIVE

WEAR TO BRAKE LINING.

® Park and turn off the tractor on a level surface. Place

gear shift lever in "N” (neutral) position. Disengage

parking brake and be sure tractor does not roll in either

direction.

Lower mower deck (if installed on tractor).

Snap out access hole cover on left side of tractor above

footrest

Loosen jam nut at clevis which will allow brake rod to be

rotated.

With pliers, from underside of chassis, unscrew brake

rod from clevis four (4) to six (6) fuii turns.

Start tractor with gearshift lever in “N- (neutral) posi

tion.

Slowly depress clutch/brake pedal to the point where

the motion drive belt stops moving. Hold clutch/brake

pedal in this position and engage parking brake. If belt

begins to move after engaging parking brake, reset

parking brake by depressing clutch/brake pedal slightly

to next notch on parking brake.

Stop engine. Screw brake rod back into clevis until

clevis pin is against rear edge of slot in brake arm. Do

not overtighten (see "IMPORTANT" above).

Tighten jam nut against clevis.

Replace access hole cover.

Testtractorforproperstoppingdistanceand declutching

as stated above. Readjust if necessary. If proper

adjustment cannot be attained, further maintenance is

necessary. Contact your nearest authorized service

center.