Troubleshooting points, Troubleshooting -26 – Sears 917.25759 User Manual

Page 26

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

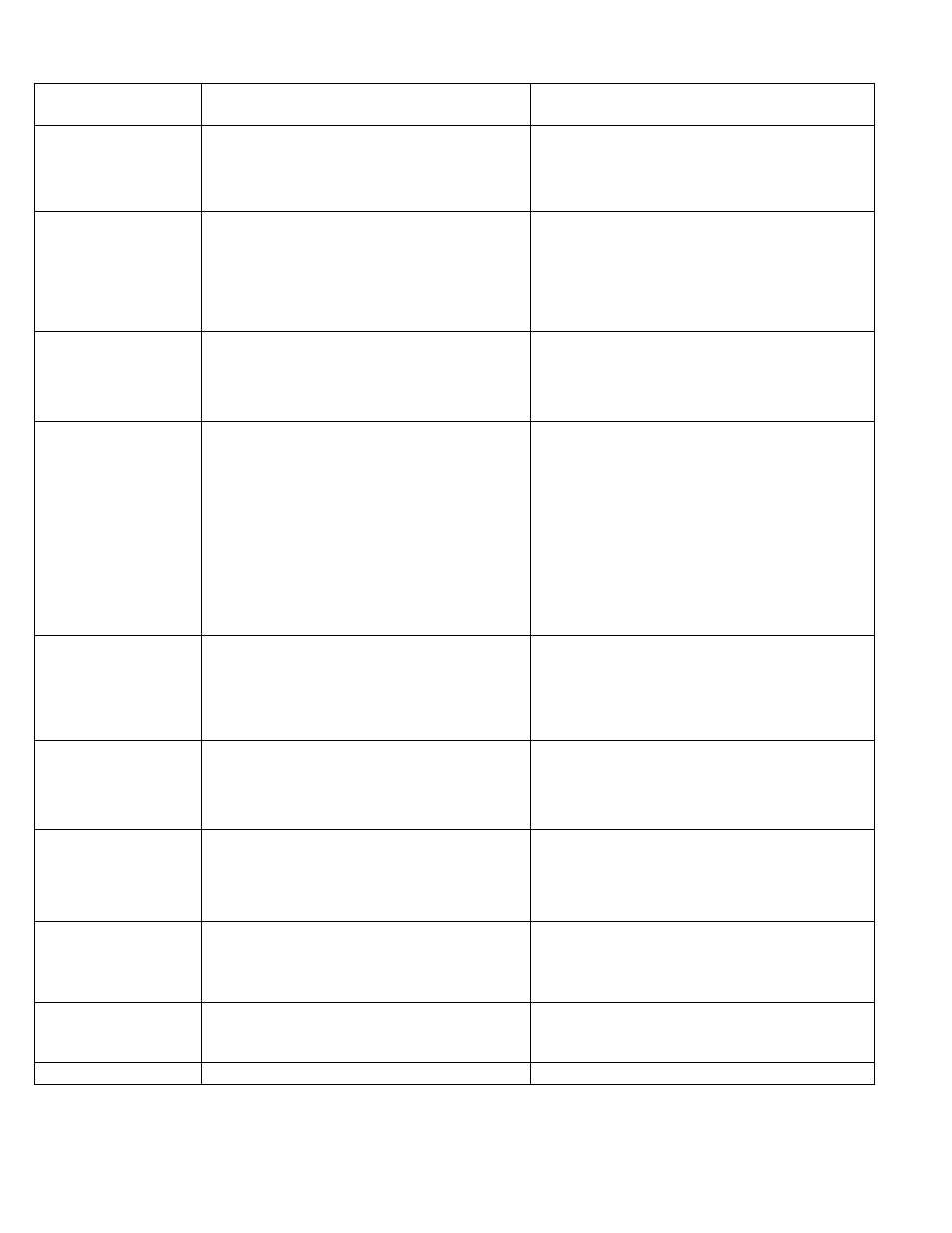

TROUBLESHOOTING POINTS

PROBLEM

CAUSE

CORRECTION

f-ngtni! eot)tmuc*i to »un

whect operator lefsyes sft.tf

with attachment Hutch

ungaqecj

’

'Faulh/ operalor-satety presence ccsntrot system.

1. Cliack wiring, switches and eofirtecttons. If not

corrected, contact

iVn

authofízerí service ctriter/

department.

Poor

cut -

yneveii

1. Worn, bent or loose triad#.

2. Mower deck rw ievei.

3. BuiWup of grass, leases, and trash under mower.

4. Beni blade mandrel.

5.

Clogged rriQwer deck vent holes from buildup of

grass, leaves, and irash around inancirsis.

1.

Replace biade. Tighten blade bolt.

2. Leve! m.ower cicrck,

3.

Clean underside of mower housing,

4.

Replace blade mandrei,

5.

Clean around mandrels to open vent holes,

Mower blades will

not

rotate

1. Obstruction in clutch mechanism.

2.

Worn/darnaged mower drive belt.

3.

Frozen i;ci#.r pyley,

4.

Frozen bfecJe mandrel.

1. Rernove obstruction.

2. Replace mower drive beit.

3.

Replace icier pofley.

'

4.

Replace blade ma.ndfsi.

Poo-r grass dischirge

1.

Engine speed too slow.

2.

Travel speed too fa.sf,

3.

Wet grass.

4.

Mower deck not level.

5.

I.ow/unaven tire air pressure.

6.

Worn, bent or loose btacie,

7.

Btidup cjf grass, leaves and trash und« mower.

8

.

Mower dffva bírit worn.

9

.

Blade,s improperly iristaHed.

10.

improper Wades Uiiacl,

11.

Ciogged mower deck vent holes from bUiltfop of

grass, Itavirs, and trash around mandreis.

1.

Place Iftfottle controi in “FAST" position-.

2.

Shift

to

slotver speed,

3.

Allo-w gra.ss

to

dry before mowing.

4.

Level mower deck.

5.

Check tires ter proper air pressure.

6.

Repl-acs/sharpen blad#. Tighten btads bolt.

7.

Clean underside of :mower housing,

8„ Replace mower drive belt.

9, Reifi-Stall Wades sharp edg-e down.

10,

Replace with biacles listed in this manual,

11.

Clear! arourtcJ mandrels to open vent holes.

Heaclight(g)

not

woillng

{if

so

ecfuippecl)

1. Switch is "OFF”,

2. Bufb(s) burned out.

3. Faulty tight switch.

4. Loose or damaged wiring,

5. Biowii fuse.

1

.

T'urn switch "ON".

2.

Rep'iace bulb(s-).

3.

C.heck/f8place light .switch.

4.

Chi-ck wiring and cormectiofl-s.

5.

He.place fuse.

Bjttr ry will

not r!i,»rrj.’

, -d - .1- I

> ' ' I'l, 1. mi 1 I i‘ i[i, )

1 •

t

1 , M, I It ¡

1-

.

Repta#® tettery,

2.

CtieeWcleBb -all connections,

3.

Replace regulator,

4-, Refalase alternator.

Tractor "creeps" with

motion control lever In

“neutrar poiiiten

(Fender shift moc(»!s only)

1

.

M'Otion control lever is out of adjustment.

1

.

A.d|ust motion control teva-r.

Loss of drive

1

.

Freewheel coniroi in "drsengaged“ position.

2.

Motion drive belt has worft. damaged or b-roten.

3.

Air trapped in transmission during shipment

or

servicing

1

.

Place freeviheel coniro-t tn “engag-ecf position.

2.

RBp-iace motics-n drive belt,

3-. Pu-rge trans-iTii-ssion,

Engine "backfires"

when tyrning engin»

“OFF"

1

.

Engine throttle control not set at “SLOW"

position; for 30^ seconds before stopping engine.

1-

.

Move thfottte control to “SLOVr pcrsitíon and allow

to Idle !-

o

-

f

30 seconds before stopping engine.

26