Vermont Casting 820 User Manual

Page 31

31

Vermont Castings Jefferson Direct Vent/Natural Vent Gas Heater

20002191

Gasket Replacement

The Jefferson Gas Heater uses a ‘tadpole’ type gasket

to seal between the glass panel and the frame. In time,

this gasket can become brittle and compressed and

should be replaced. New gasket is available from your

dealer.

Shut off the gas supply and allow the stove to cool.

Wear safety goggles and a dust mask.

1. Remove the Front, Glass Frame and Glass Panel.

(Figs. 59 & 60) Remove the old gasket. Use a razor

blade to separate the glass and gasket from the

frame, and to clean the glass of any remaining

cement or bits of gasket. Use a cold chisel if neces-

sary.

2. Determine the correct length of gasket by laying it

out around the edge of the glass. Allow an extra 1 -

2” (25-50mm). Mark the spot to be cut. Use a utility

knife.

3. Starting on a long edge, remove about 6” of the

protective paper strip and apply the flat adhesive

face of the gasket around the outside-facing edge of

the panel. Continue around the panel, applying a

bout 6” at a time and being careful to not stretch the

material. Do not overlap the gasket ends. (Fig. 61)

4. Apply a thin bead of high temperature silicone

rubber sealant along the inside corner of the glass

frame, all around the perimeter. Place the flat

gasketed side of the glass panel back into the steel

frame. Pinch the rounded inside-facing gasket

material to bulk it up.

5. Replace the glass frame and front panel as previ-

ously described.

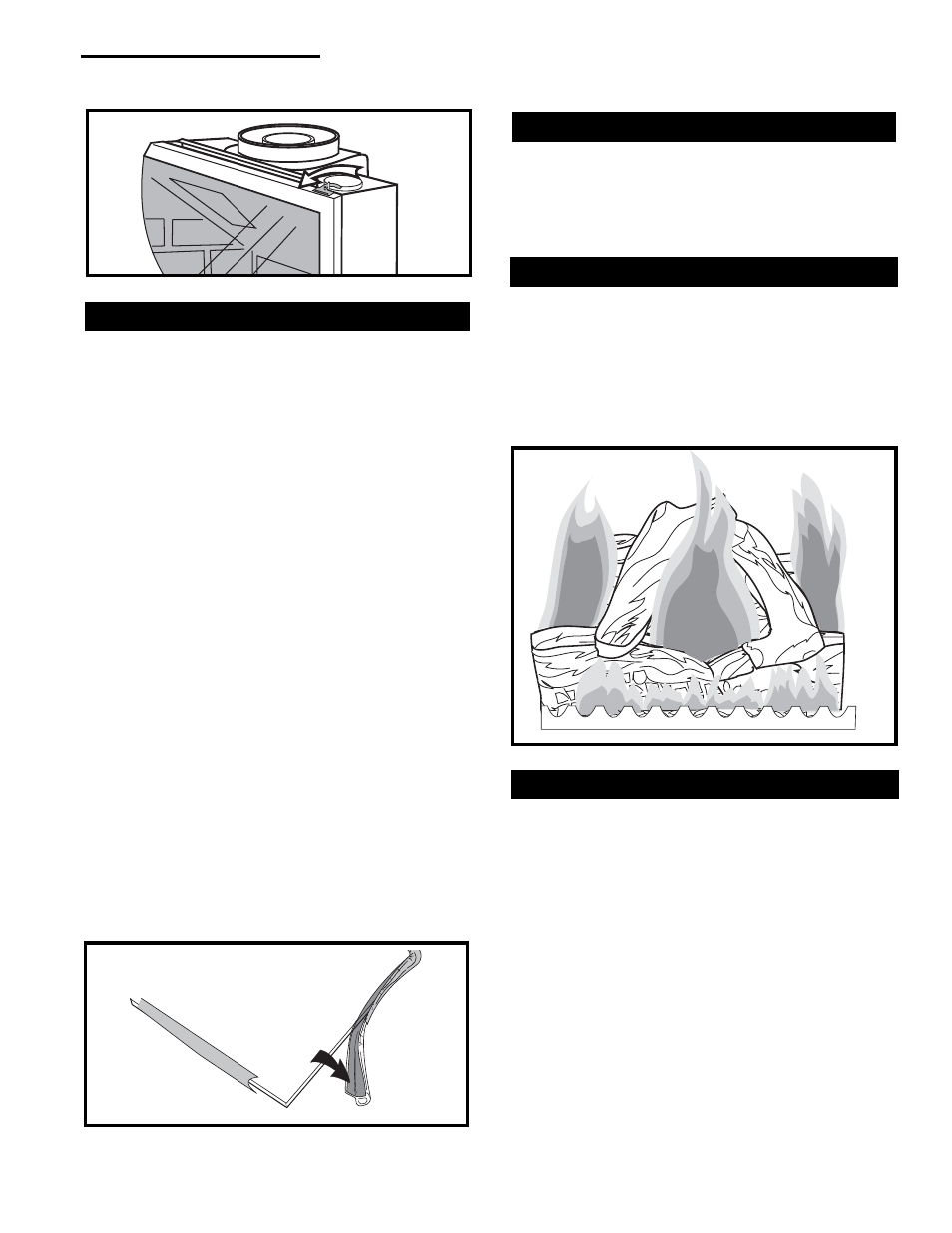

Check the Gas Flame Regularly

To ensure that the stove is operating properly, check

the flames periodically to confirm that they match

Figure 62. The flames will be blue during the first 15-20

minutes of operation, and will gradually turn to yellow

after that.

Do not use your stove if the flame pattern differs from

that shown here. Contact your Vermont Castings dealer

or a qualified technician for help.

Inspect the Vent System Annually

Have the vent system inspected annually by a qualified

technician. Shut off the main gas supply before inspect-

ing the system. Both the inner exhaust pipe and the

outer combustion supply pipe must be checked to

confirm that they are unblocked and in good condition.

Stove Disassembly

If there is ever a need to remove the firebox assembly

from the stove shell, support the firebox with solid

stands about 6” (150mm) tall under the left and right

outer edges of the firebox base. Do not set the firebox

assembly directly on the floor; this can damage the

control valve and/or the gas lines from the valve to the

firebox.

Before removing the firebox from the shell, disconnect

the on/off switch wires from the valve. If the assembly

includes the optional fan, disconnect the fan rheostat. If

the installation includes a wall thermostat, disconnect

the thermostat leads from valve.

Disconnection and reconnection to the gas line should

only be done by a qualified gas service technician.

Upon reinstallation, the vent system must be sealed to

the firebox as shown in the installation section, Page

14. Also be sure the logs are placed in the firebox

correctly, as shown on Page 20.

ST179

Fig. 61 Wrap the gasket material around the outside edge of

the glass.

ST234

Fig. 62 Correct flame pattern.

ST208a

Fig. 60 Release the latches to release the glass frame.