Carrier 50BA User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Air-Cooled Condenser Connections (50BB Con

denserless Units) — Install air-cooled condenser in

accordance with Installation Instructions shipped

with condenser. Consult Carrier System Design

Manual for standard refrigerant piping techniques.

Connection locations of liquid and hot gas service

lines are shown in Fig. 1 and 2. Condenserless units

are shipped with a holding charge (Table 1). After

refrigerant connections are made, evacuate, leak

test and charge system as described in Charging the

System.

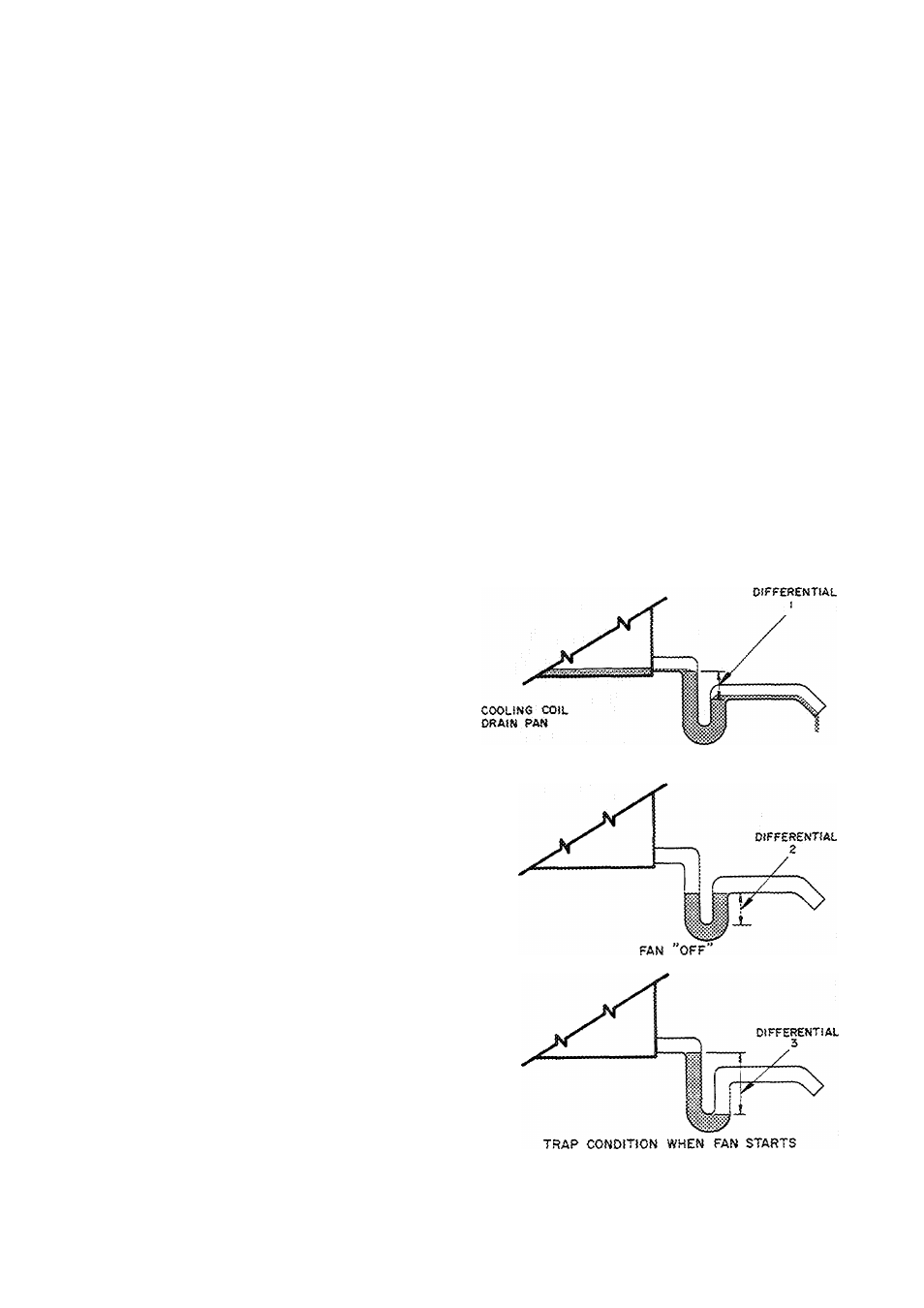

Condensate Drain — Install a trapped condensate

drain line at unit drain connection (Fig. 1 or 2).

Figure 3 shows proper trap design.

Determine design negative static pressure. This

pressure is not the same as fan total pressure,

which includes pressure losses downstream as well

as upstream of the indoor air fan. Always assume

the worst conditions, such as having return air

filters clogged with dirt. Differential 1 must be

equal or larger than negative static pressure at

design operating conditions. Store enough water to

prevent losing the trap seal (Differential 2). This

must be equal to or larger than one-half the

maximum negative static pressure. When the fan

starts. Differential 3 is equal to the maximum

negative static pressure.

Do not use drain line smaller than size shown in

Fig. 1. Pitch drain downward to open drain or

sump. Fill trap with water to make an air seal.

Observe all local sanitary codes.

Power Supply Wiring — Unit is factory wired for

voltage shown on unit nameplate. Provide an

adequate fused disconnect switch within sight of

unit and out of reach of children. Provision for

locking switch open (off) is advisable to prevent

power from being turned on while unit is being

serviced, especially if disconnect switch is not

visible from unit. Disconnect switch, fuses and

field wiring must comply with National Electrical

Code and local requirements.

Install strain relief and connector in unit side

panel and control box electrical connection open

ings in accordance with local codes. See Fig. 1.

Route power wires to power terminals as shown on

unit label diagram and Fig. 4.

Affix crankcase heater sticker in instruction

packet to unit disconnect switch (50BB units).

Voltage to unit during operation must be

within voltage range indicated on unit nameplate

and Table 2. Table 2 also contains information

regarding wire and fuse sizes required. Power

phases must be balanced within 2%. Contact local

power company for correction of improper voltage

or phase unbalance. Operation of unit on improper

line voltage or with excessive phase unbalance may

damage unit electrical components.

Air-Cooled Condenser Control Wiring — Connect

outdoor fan relay as shown on unit label diagram

and Fig. 4. Outdoor fan motor must not exceed

1/2 hp at 125 or 250 volts.

Remote Thermostat Installation — Disconnect the

factory-installed thermostat (230-volt) and install

remote thermostat (24-volt) as follows;

1. Obtain these field-supplied components:

Transformer (Carrier Part No. HT01AA140)

Remote Thermostat Relay (Carrier Part No.

HN61KJ007)

Remote Thermostat, 24-volt (type as desired)

Suitable lengths of Class II wire and connectors

as required.

Study Fig. 4.

Disconnect at compressor contactor terminal

C-DU2 the red wire between C-DU2 and the

unit thermostat terminal R. Tape end of loose

wire and tape wire to side of unit.

Install transformer and remote thermostat relay

in unit main control box as shown.

5. Locate 24-volt thermostat in conditioned space

in accordance with instructions packed with

thermostat. Use one thermostat per unit on

multiple unit installations.

6. Connect wires in accordance with all applicable

codes. Accessory electrical connection opening

in unit side panel and control box is shown in

Fig. 1.

2

.

3.

4.

FAN RUNNiNG AND CONDENSATE ORAiNiNG

m

0

Fig. 3 — Condensate Drains