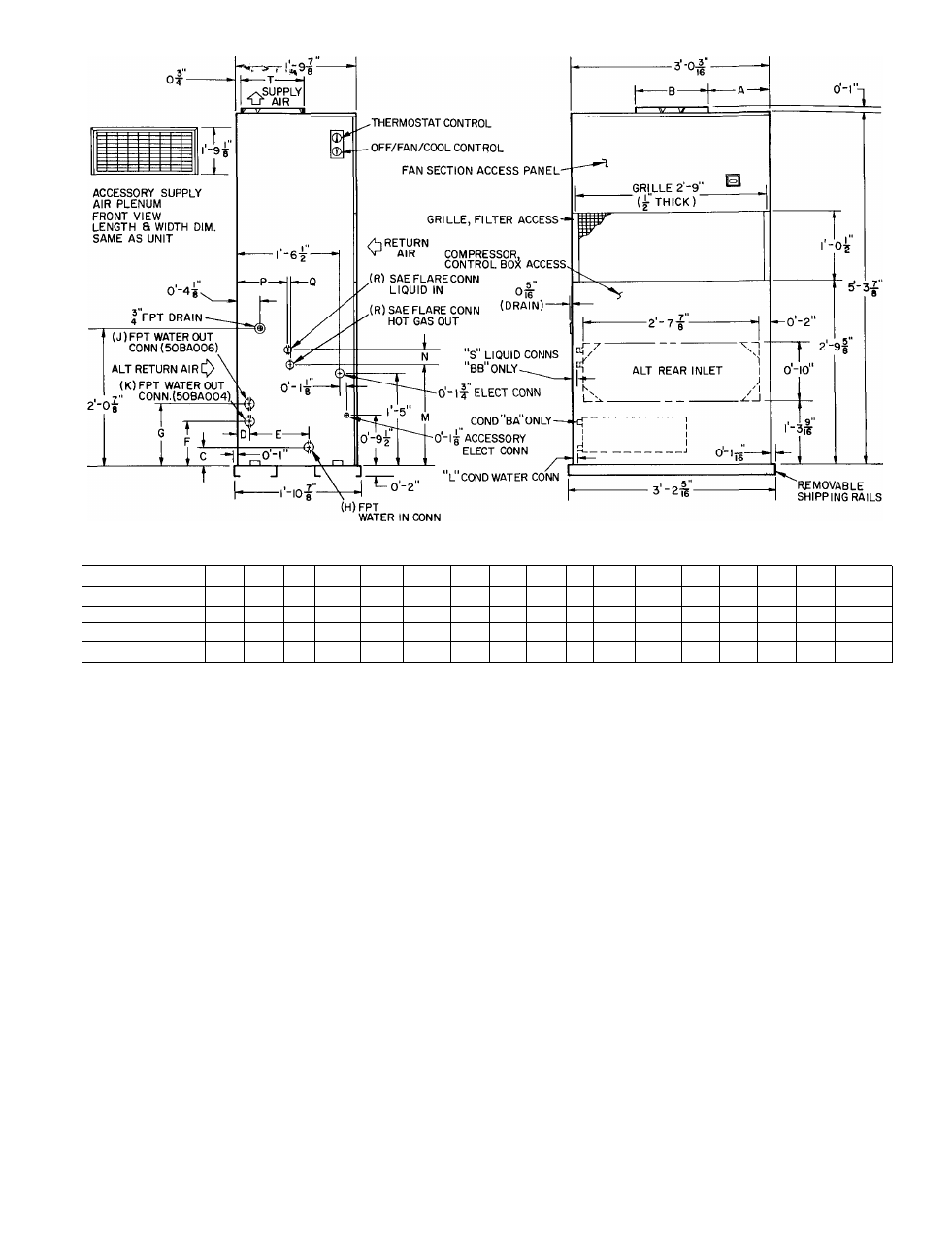

Fig. 1 — base unit dimensions – Carrier 50BA User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

LEFT SIDE VIEW

FRONT VIEW

DIMENSIONS (ft-in.)

UNIT A

B

c

D

F

F

G

H

J

K

L

M

N

P

Q

R

s

T

50BA004Ì 1-1OV

2

1-1

0-3%

0-2

0-1 OVa

0-8

_

O-OV

2

0-0V2

0-y«

_

_

_

—

_

_

l-UXe

50BB004 Ì 1- OV,

1-1

o-ey«

o-oy«

0-0V2

0-r/a

l-l“/i6

50BA006Ì 0-1 Oy«

1-3

0-3 V

b

0-2

0-1 OV

b

_

0-1 1 V

b

0-0%4

o-oy4

_

0-V2

_

_

—

—

-

1 -4yi6

50BB006] b-lOVs

1-3

-

-

-

-

-

-

-

-

l-6^/26

0-2^/l6

O-S'/a

o-oy«

0-0V2

0-1 V

b

l-4yie

Certified dimension drawings available on request.

NOTE

Minimum required clearance at back and right side of unit is zero

Clearance above and at left of unit depends on space required for

accessory

plenum,

ductwork,

condenser

piping,

accessory

heater

piping, condensate drain line and power wiring Clearance required

at front of unit for service access and free return airflow is 2 feet

Fig. 1 — Base Unit Dimensions

2. Attach 1-in. flange to unit back panel or attach

a flanged, flexible duct connection directly to

unit as desired. If an outdoor makeup air

damper is to be installed, attach directly to unit

back panel and install flexible connection

between damper assembly and remaining duct

work. Use accepted ductwork installation

procedures. Follow all applicable codes.

3. Restrict or completely blank off the standard

return air opening with a field-fabricated filler

panel using dimensions shown in Fig. 1. This

panel must be removable for service access.

Refer to Service, Return Air Grille Removal as

required.

Water-Cooled Condenser Connections (50BA

Units) — Connect condenser water supply and

return lines to connections shown in Fig. 1. To

prevent condenser inlet and outlet stubs from

twisting when connecting water lines, hold them

firmly with a wrench at the FPT hex fitting. Do

not use water lines smaller than connection sizes

all applicable plumbing and

shown. Observe

sanitary codes.

Install a water regulating valve in water supply

line outside unit cabinet as follows:

1. Route water regulating valve capillary and flare

nut to fitting on refrigerant liquid line (Fig. 2)

using any convenient unused opening on side of

unit. Use a grommet in unit panel to prevent

chafing of capillary line.

Remove cap from liquid line fitting.

Insert the cotter pin (taped to liquid line near

fitting) split end first into water regulating valve

flare nut.

Connect flare nut to fitting. Round end of

cotter pin will depress fitting core, thus opening

fitting to allow refrigerant pressure to act on

water regulating valve. Tighten flare nut to

prevent leakage.

The fitting will automatically seal (close) when

flare nut is loosened and removed; however, a

slight amount of refrigerant is lost each time.

Do not lose cotter pin.

(Continued on P. 4)

2

.

3.

4.

5.

i