Carrier 58SX040-IBC User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

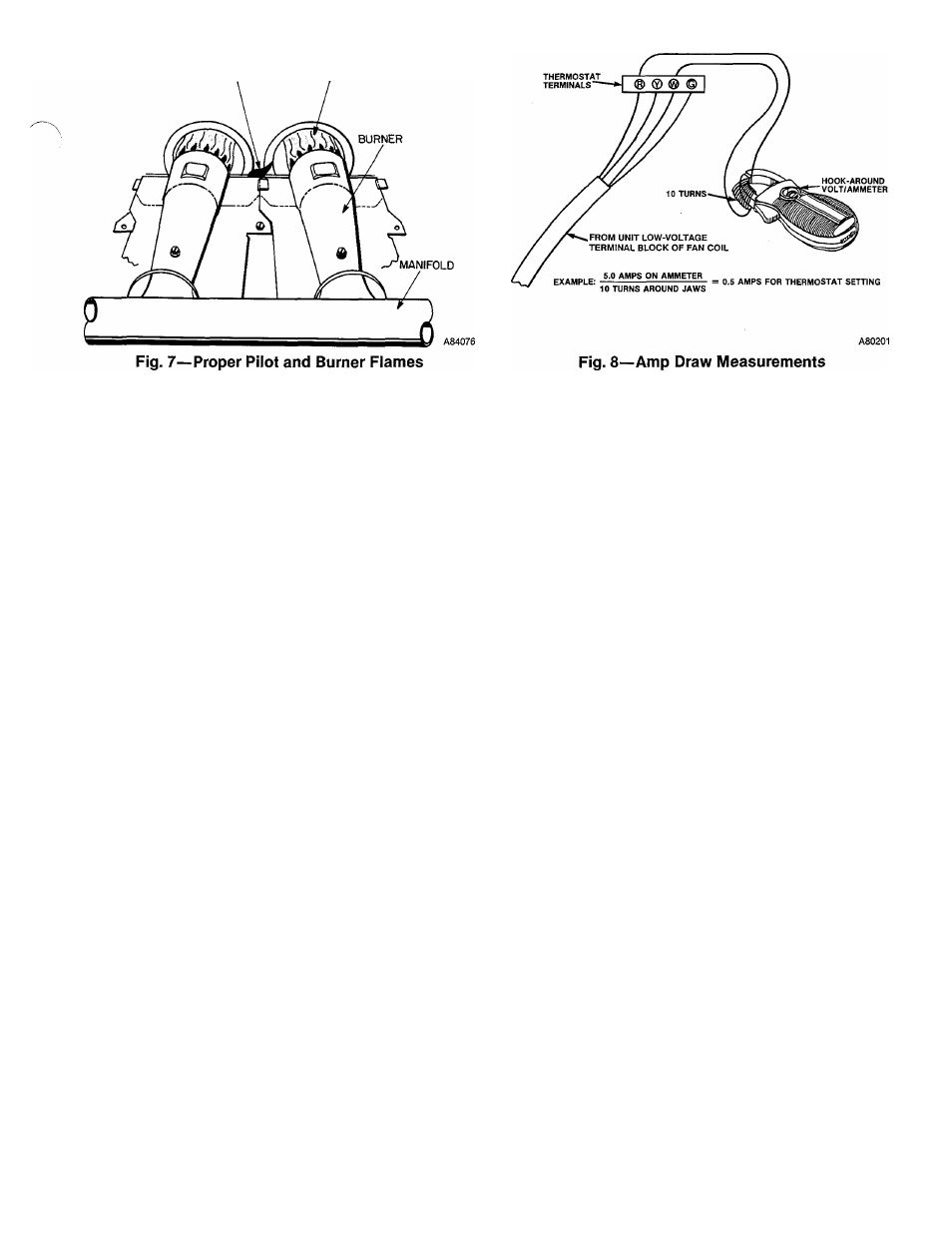

PILOT FLAME BURNER FLAME

4. High Altitude—Input ratings apply for altitudes up to

2000 feet. Ratings for altitudes above 2000 ft must be

4% less for each 1000 ft above sea level.

Temperature Rise—

Do NOT operate furnace outside range

of temperature rise specified on unit rating plate. Determine

air temperature rise as follows:

1. Place thermometers in retmm and supply ducts as near

furnace as possible. Thermometers must not “see”

heating element or radiant heat may affect readings.

This practice is particularly important with straight-

run ducts.

2. When thermometer readings stabilize, subtract return-

air temperature from supply-air temperature to deter

mine air temperature rise.

3. Adjust temperature rise by adjusting blower speed.

Increase blower speed to reduce temperature rise.

Decrease blower speed to increase temperature rise.

Thermostat Heat Anticipator Adjustment—

Thermostat

heat anticipator must be set to match amp draw of compo

nents in R-W circuit. Accurate amp draw measurements can

be obtained at thermostat subbase terminals R and W. Fig

ure 8 illustrates an easy method of obtaining these measure

ments. Amp reading should be taken after blower has

started on its heating speed.

Safety Check of Limit Control—

Control shuts off combus

tion gas supply and energizes circulating-air blower motor if

furnace overheats.

Recommended method of checking this limit control is to

gradually block off return air after furnace has been operat

ing for at least 5 minutes. As soon as limit control func

tions, return-air opening should be unblocked to permit

normal air circulation. By using this method to check limit

control, proper functioning can be determined and furnace

will fail-safe if circulating air supply is restricted or motor

fails. If limit control does not function during this test, iden

tify and correct cause of malfunction.

Safety Check of Flow-Sensing Switch—

This control

proves operation of draft inducer. Check switch operation as

follows:

1. Turn off 115-v power supply to furnace.

2. Remove control access panel and disconnect inducer-

motor lead wires from inducer printed-circuit board.

3. Turn on 115-v power supply to furnace.

4. Close thermostat switch as if making normal furnace

start. When flow-sensing switch is functioning prop

erly, gas should not flow to pilot and ignitor should not

operate. If either pilot gas flow or ignitor operation

occurs when inducer motor is disconnected, shut fur

nace down immediately. Determine cause of malfunc

tion and correct condition.

5. Turn off 115-v power supply to furnace.

6. Reconnect inducer-motor leads, reinstall control access

panel, and turn on 115-v power supply.