A caution, A warning – Carrier 58EFA User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

d. After oiling motor, wipe excess oil from motor housing.

e. Replace dust caps or plugs on oil ports.

9. Remove blower wheel from housing.

a. Mark blower wheel orientation and cutoff plate location to

insure proper reassembly.

b. Remove screws securing cutoff plate and remove cutoff

plate from housing.

c. Remove blower wheel from housing.

10. Clean blower wheel and motor using a vacuum with soft brush

attachment. Be careful not to disturb balance weights (clips)

on blower wheel vanes. Do not drop or bend wheel as balance

will be affected.

11. Reassemble blower by reversing items 9.a. through 9.c.

Ensure wheel is positioned for proper rotation.

12. Reassemble motor and blower by reversing items 3 through 7.

Reconnect motor ground wire.

A

CAUTION

Ensure the motor is properly positioned in the blower

housing. The motor oil ports must be at a minimum of 30°

above the horizontal centerline of the motor after the blower

assembly has been reinstalled in the furnace.

13. Reinstall blower assembly in furnace.

14. Connect electrical leads to motor speed selector; do not force

leads.

15. Turn ON electrical supply and check for proper rotation and

speed changes between heating and cooling.

Step 3—Cleaning Heat Exchangers and Burners

The following items should be performed by a qualified service

technician:

If it becomes necessary to clean the heat exchanger because of

carbon deposits, soot, etc., proceed as follows:

NOTE: Deposits of soot and carbon indicate a problem exists that

needs to be corrected. Action must be taken to correct the problem.

1. Turn OFF gas and electrical supplies to furnace.

2. Using a backup wrench, disconnect gas supply at ground joint

union. Remove gas pipe from gas valve.

3. Disconnect electrical wiring from gas valve.

4. Remove bumer/manifold assembly as follows:

a. Remove air inlet plate/burner removal cover.

b. Remove manifold retention plate from front of unit.

c. Loosen screws in manifold retention plate at rear of unit.

d. Disconnect wiring to ignition electrode/flame sensor.

e. Remove bumer/manifold assembly from unit.

5. Place burner/manifold assembly on flat work surface and

clean burner ports. Use a soft brash to loosen dirt, then

vacuum.

6. Using a small rubber mallet, gently tap each burner opening to

loosen any debris in heat exchanger cells.

7. Brush each heat exchanger cell using a nylon heat exchanger

brush with a long, flexible handle.

8. Vacuum each heat exchanger cell and burner box with a

crevice tool attachment.

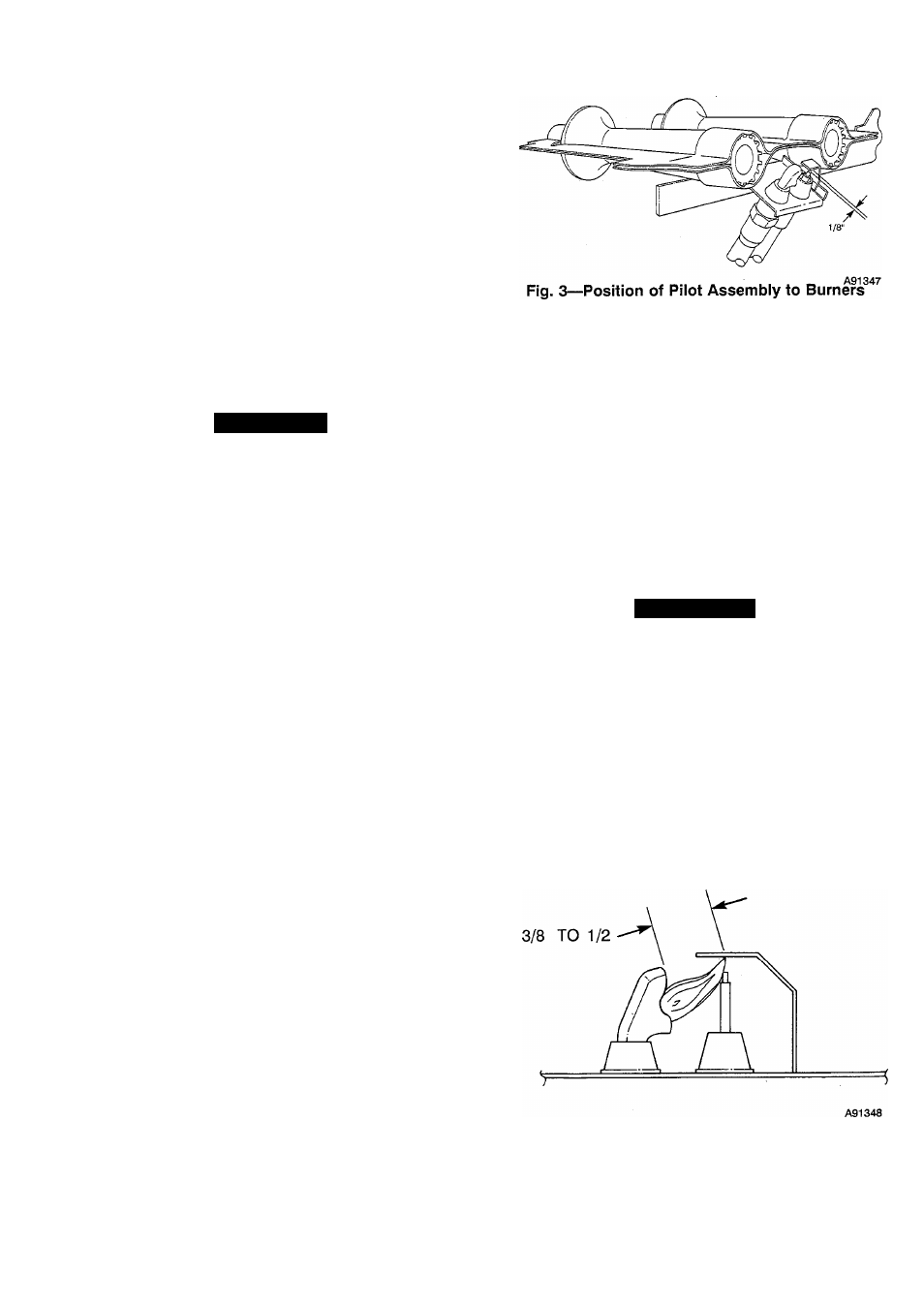

9. Check position and alignment of pilot assembly to burners and

ignition electrode to ignition hood. (See Fig. 3.)

10. Reinstall burner/manifold assembly and front manifold reten

tion plate.

11. Tighten screws securing rear manifold retention plate.

12. Reconnect wiring to ignition electrode/flame sensor.

13. Reinstall air inlet plate/bumer removal cover.

14. Using wiring diagram (Fig. 7.) reconnect wiring to gas valve.

15. Apply joint compound (pipe dope) sparingly to male ends of

gas pipe and reinstall gas pipe in gas valve.

NOTE: Joint compound must be resistant to the action of propane

gas.

16. Reconnect ground joint union.

17. Turn ON gas and electrical supplies to furnace.

18. Check gas supply line for leaks.

A

WARNING

Never use matches, candles, flame, or other sources of

ignition to check for gas leakage. Use a soap-and-water

solution. Failure to follow this warning could result in a fire,

personal injury, or death.

19. Check furnace operation through 2 complete operating cycles.

Look through vent openings in burner enclosure to check

burners. Main burner flames should be clear blue, almost

transparent. Pilot flame should be soft blue in color, well

defined, and must provide good impingement of the ignition

electrode/flame sensor. Pilot flame should extend above

burner carryover port to provide proper burner ignition. (See

Fig. 3, 4, and 5.)

Fig. 4—Position of Piiot to Ignition Electrode/FIame

Sensor