Service, Lubrication, To add or remove compressor oil – Carrier 38JB User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Every full turn counterclockwise decreases load

point by 7.5 psig.

PRESSURE

DIFFERENTIAL

(difference

be

tween cylinder load and unload points) is adjust

able from 6 to 22 psig. To adjust, turn pressure

differential adjustment counterclockwise to its back

stop position. In this position, differential is 6 psig.

Turn adjustment clockwise to desired pressure

differential. Every full turn clockwise increases

differential by 1.5 psig.

SERVICE

Turn off main power before servicing unit.

Condenser Coil

— Remove dirt and debris from

coil as required. Clean with a stiff brush, vacuum

cleaner or compressed air.

Condenser Air Fan Adjustment

— Speed (see

Table 1) and alignment is factory set, adjust as

follows;

TO CHANGE FAN SPEED:

1. Loosen fan belt by loosening fan motor mount-

ing plate bolts.

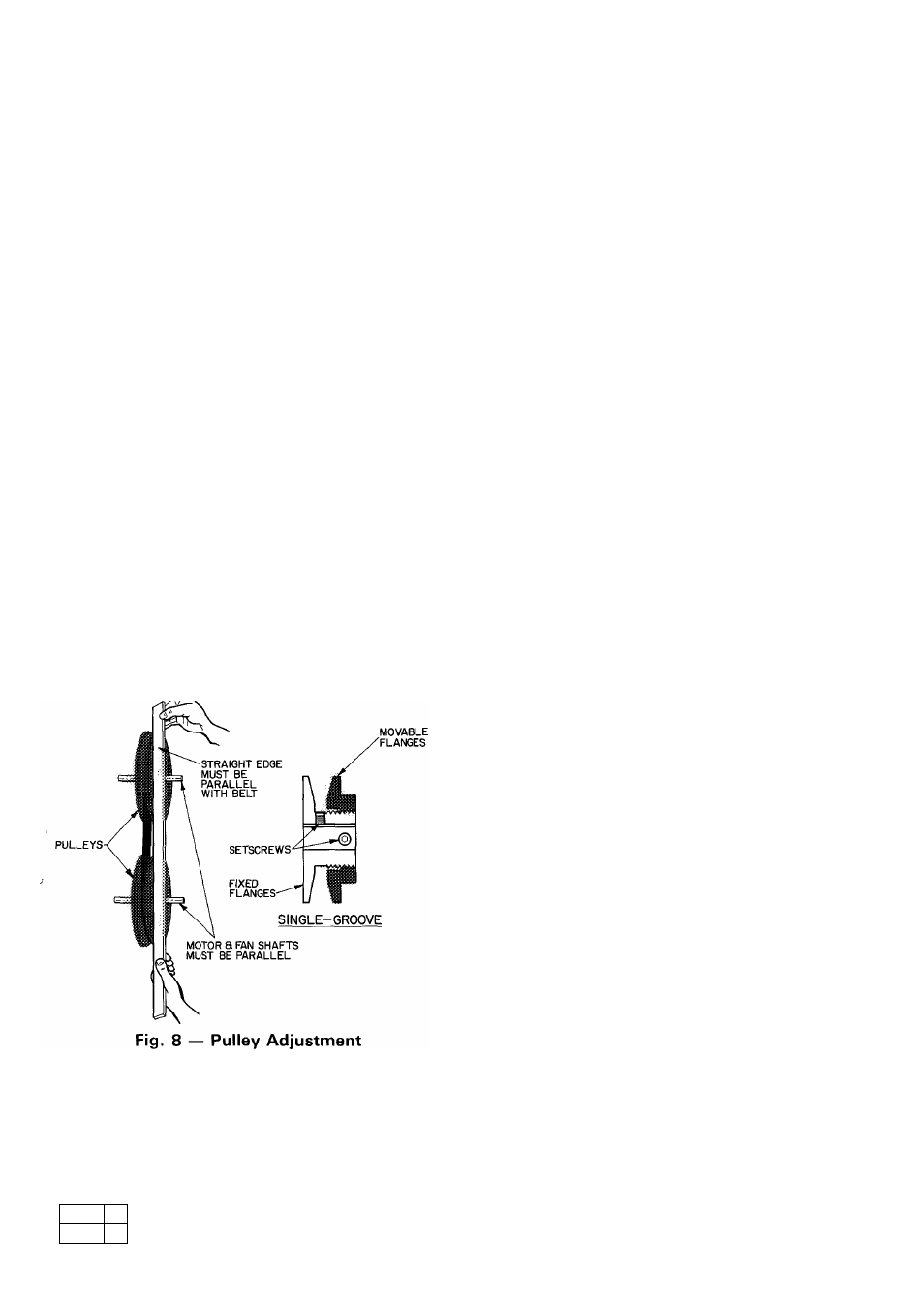

2. Loosen pulley movable flange setscrews (Fig. 8).

3. Screw movable flange toward fixed flange to

increase speed and away from fixed flange to

decrease speed.

Increasing fan speed increases load on motor. Do

not exceed maximum fan speeds (Table 1).

4. Tighten movable flange setscrews at nearest flat

surface of pulley hub.

TO ALIGN FAN AND MOTOR PULLEYS —

Loosen fan pulley setscrews and slide fan pulley

along fan shaft. Make angular alignment by loosen

ing motor from mounting plate. Check alignment

with a straight edge (Fig. 8).

TO ADJUST BELT TENSION — Loosen motor

mounting plate bolts. Slide motor mounting plate

as required to attain approximately 3/4-in. belt

deflection with one finger.

Lubrication

FAN MOTORS have sealed lubricated bearings.

No provisions for lubrication are made.

FAN SHAFT BEARINGS have been factory

greased. After first 6 months of unit operation,

regrease twice a year, preferably prior to each heat

ing and cooling season. Add grease slowly with shaft

revolving until grease rapidly oozes from pressure

relief hole in grease fitting.

COMPRESSOR has its own oil supply. Loss of oil

due to a leak in the system should be the only

reason for adding oil after the system has been in

operation. Sight glass should be 1/2 full of oil.

To Add or Remove Compressor Oil

1. Pump down compressor to 2 psig and close

suction and discharge service valves. Vent re

maining pressure in compressor to atmosphere.

2. Add oil thru oil filler connection.

3. To remove oil, remove compressor crankcase oil

drain plug.

Refer to Standard Service Techniques Manual,

Chapter 1, or 06D Compressor Service Instructions

for complete instructions on checking, adding or

removing compressor oil.

Refrigerant Charge

— The approximate unit

charge is listed in Table 1. Refer to Carrier Stand

ard Service Techniques Manual, Chapter 1,

Refrigerants.

A clear sight glass does not always indicate ade

quate refrigerant charge. If a low charge is sus

pected, purge until sight glass flashes. Block

condenser coil air inlets to maintain 300 ± 5 psig

discharge pressure. Charge slowly until sight glass

clears, then add an additional charge as specified

in the instructions for the evaporator unit.

If low-pressure switch is jumpered for charging,

remove jumper.

For replacement items use Carrier Specified Parts.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1

Tab

3a

Form 38JB-3SI Supersedes 38JB-1 SI

Printed in U S A

9-80

PC111

Catalog No 533-889