Step 6 — make piping connections, 6 — liquid and suction line locations in top panel – Carrier 38JB User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 2 — Electrical Data (60-Hz, 3-Ph)

FLA

-

Kw

—

LRA —

MCA -

UNIT

VOLTS*

COMPRESSOR

FAN

UNIT POWER

SUPPLYt

38 JB

Model

Nameplate

Min

Max

RLA

LRA

FLA

Kw

MCA

Max Fuse

Amps

520

208-230

187

254

64 0

266

16 2

3 73

~ 97 5‘

150

016

610

460

414

508

28 6

120

7 1

3 73

43 4

70

110

575

518

632

23 6

96

5 6

3 73

35 6

50

520

208-230

187

254

44 3

r 170

, g --

3 73

117 0

150

024

610

460

414

508

20 0

77

7 1

3 73

52 6

70

110

575

518

632

15 7

62

5 6

3 73

41 5

50

RLA

Full Load Amps (fan motor)

Total Kilowatts

Locked Rotor Amps

Minimum Circuit Amps Complies with NEC, Section

430-24

Rated Load Amps (compressor)

‘Units are suitable for use on electrical systems where voltage

supplied to the unit terminal block is not below minimum or

above maximum

fFuse only

NOTES

1 Control circuit breaker size is 3 2 amps for all units

2 Unit 38JB024 has 2 compressors; RLA and LRA values apply

for each

UNPOADER

suction

.

line

, , .C.Q.IyiPRESSOR

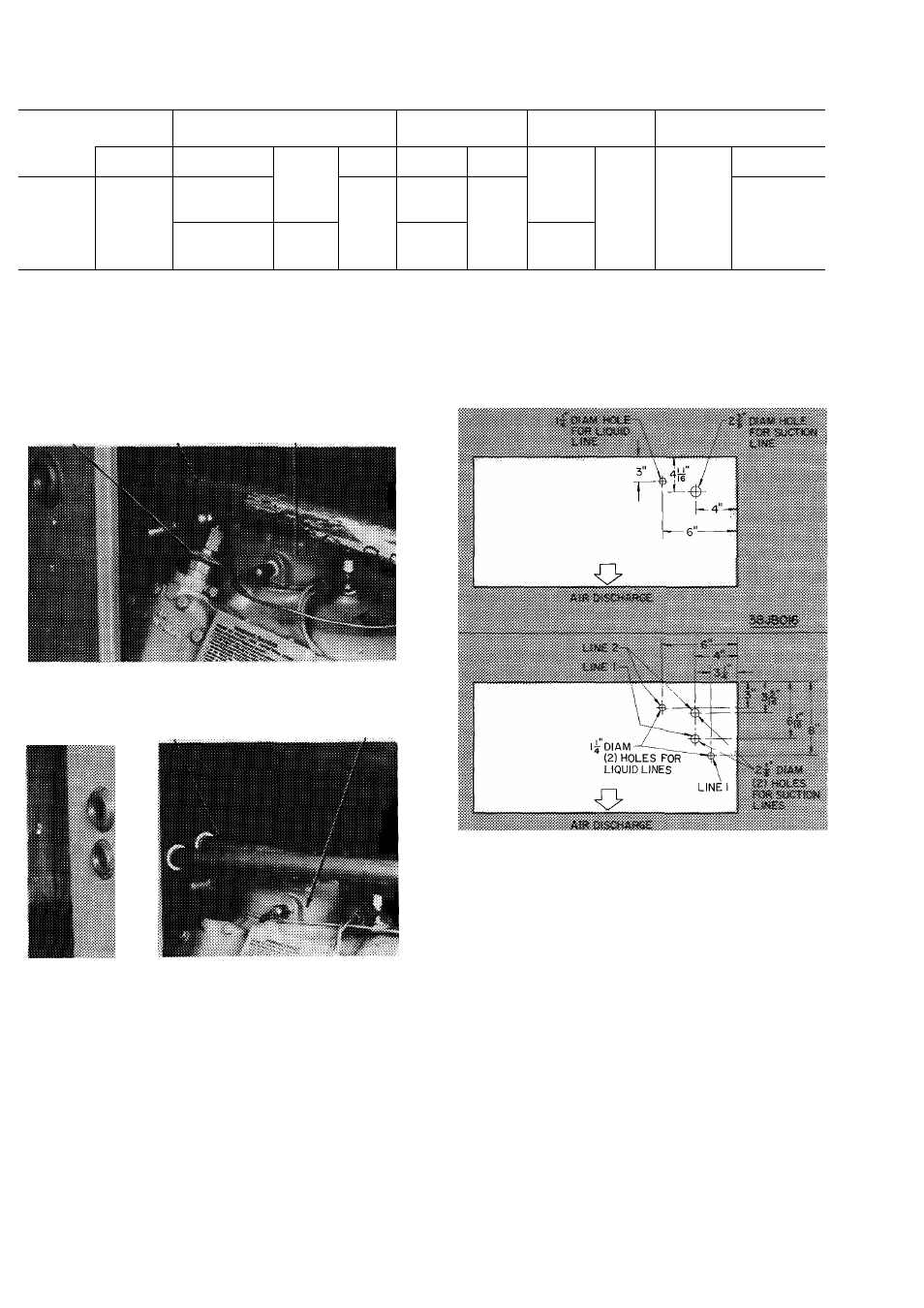

38JB016

SUCTION LINES

COMPRESSOR

38JB024

Fig. 5 — Piping Connections

Step 6 — Make Piping Connections

Connect condensing unit to a fan coil unit using

field-supplied refrigerant grade tubing. Do not use

damaged or contaminated tubing. Evacuate or

purge field-supplied tubing.

The 38 JB is shipped with a holding charge in the

condensing coil and compressor. When using head

pressure dampers, connect line to head pressure-

Fig. 6 — Liquid and Suction Line Locations

in Top Panel

actuated piston operator prior to pumping system

down. Evacuate remainder of system before

charging.

CONNECT REFRIGERANT LINES — See Fig. 5.

When suction lines are piped thru the front or top

of the 38JB016, one 1-3/8 in. 90° elbow is required;

two 1-1/8 in. 90° elbows are required on the

38JB024. See Fig. 6 for hole locations.

When liquid lines are piped thru the front of unit

elbows are not required. When liquid lines are piped

thru top of unit, two 5/8-in. 90° elbows are

required. See Fig. 1 and Fig. 6 for line locations.