Step 4 — provide for unit condensate disposal – Carrier 38JB User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

&■

“T^

CONDENSER COIL

f

t

?

-----

g-------

Contact local power company for correction of

improper line voltage.

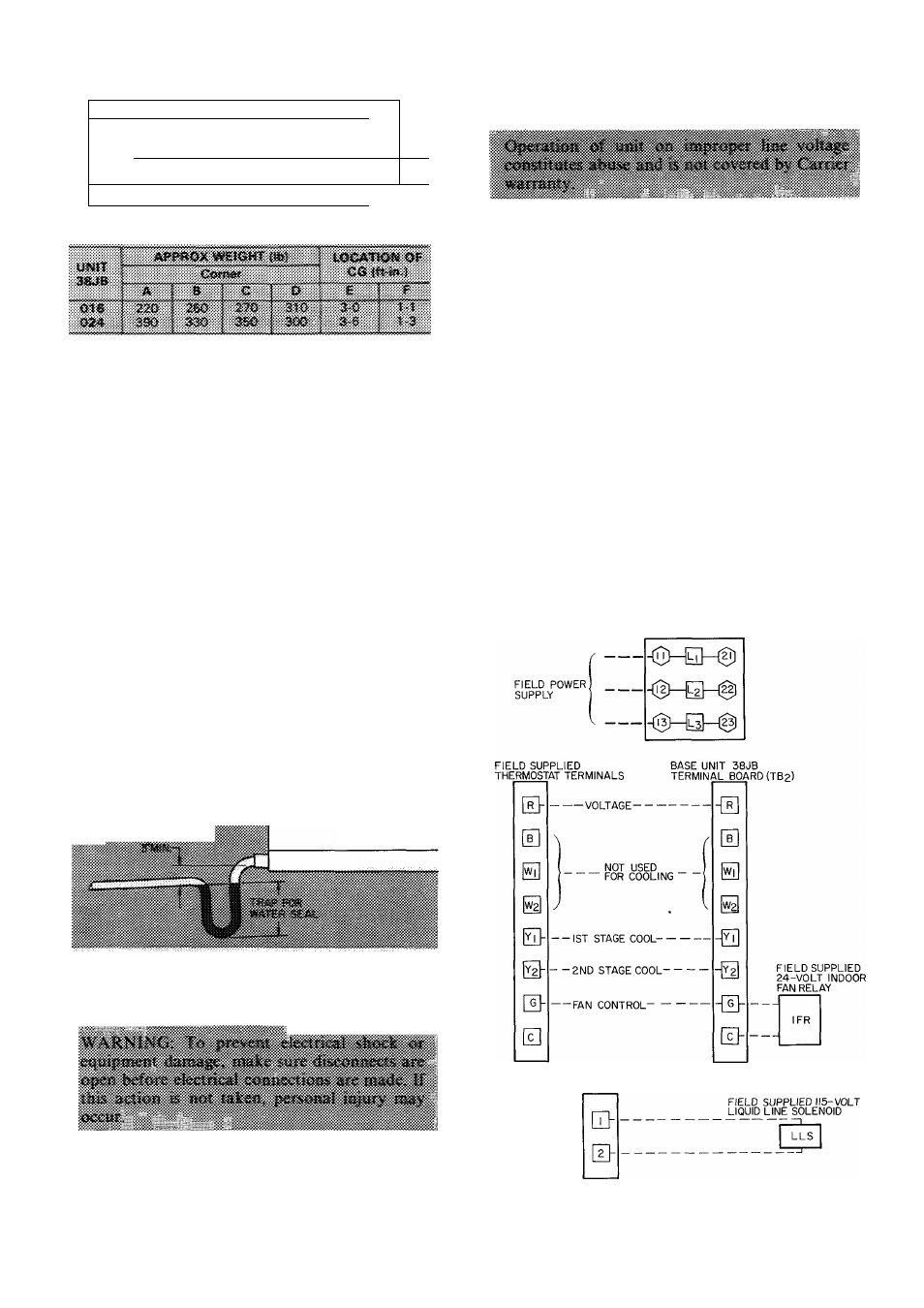

Fig. 2 — Weight Distribution

vapor barrier. If ducts are not insulated, install

dampers in wall openings to prevent cold air from

entering ducts and unit. Insulate inside of duct

within 12 in. (minimum) of unit. Also insulate

bottom of unit (basepan) to prevent condensation

from forming on unit if unit is installed off the floor.

Install louvers in wall openings to prevent rain

from entering ducts and unit. Arrange louvers or

other air deflection baffles to prevent recirculation

of outdoor airflow thru condenser.

If condenser air inlet filters are not used, provide

an access door in condenser air inlet duct for

coil cleaning.

Step 4 — Provide for Unit Condensate

Disposal

BASEPAN DRAIN — Trap 1/2-in. diameter drain

in unit basepan for proper condensate disposal, see

Fig. 3. Refer to Carrier System Design Manual,

Part 3 for additional trap design details.

'„'g

38JB

UNIT

Fig. 3 — Trap for Drain

Step 5 — Make Electrical Connections

Field wiring must comply with local and national

fire, safety and electrical codes. Voltage to unit

must be within 2% of voltage and 10% of current as

indicated on nameplate. See Table 2.

BRING LINE POWER LEADS INTO UNIT —

Install airtight conduit connectors in side panel

knockouts. Route all wires thru connectors to

terminal blocks in control box. Refer to Fig. 4 and

unit label diagram. Use copper, copper-clad alumi

num, or aluminum wire from power supply. If

aluminum wire is used, coat wire ends with a corro

sive inhibiting flux. Install unit ground.

CONNECT CONTROL POWER WIRING — See

Fig. 4. Make field power wire connections to

terminal board (TBl).

Connect field-supplied thermostat to terminal

board (TB2). Terminals C and G are provided for

field-supplied

indoor

fan

relay

connections.

Operate thermostat and indoor fan relay on 24 volts.

The 38JB016 has a third terminal board (TB3)for*

115-volt liquid line solenoid valve connections. Use

7/8-in. diameter knockout. See Fig. 1 for wiring^

liquid line solenoid valve into control box.

BASE UNIT 38JB

TERMINAL BOARD (TB|)

BASE UNIT 38JB0I6 ONLY

TERMINAL BOARD (TB

3

)

Fig. 4 — Electrical Connections