Start-up – Carrier 38JB User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

l^íd Wnèbf $

Ompws&ún'

For piping instructions, refer to the Carrier

System Design Manual. Refer to Refrigerant

Charge and Carrier’s Standard Service Techniques,

Chapter 1, Refrigerants, when charging unit.

START-UP

Make sure unit has been installed in aeeordance

with installation instructions and all applicable

eodes. Check the following items before starting

unit.

Compressor Mounting

— Loosen eompressor

hold-down bolts until sidewise movement of flanged

washers under bolt heads is possible. Do not loosen

completely. Bolts are self-locking and retain

adjustment.

Internal Wiring

— Check all electrical connections

in unit control box, compressor terminal boxes and

other electrical components. Tighten as required.

Refrigerant Shutoff Valves

— Open (backseat)

compressor service valves fully. Replace and tighten

valve caps to prevent leaks. Open liquid line valve

in a similar manner.

Crankcase Heater

— Energize heater 24 hours

prior to start-up to prevent loss of oil in compressor.

Area near heater element should be warm to the

toueh.

Heater is automatically energized when com

pressor is stopped and de-energized when com

pressor is operating.

Compressor Oil Sight Glass

should be 1/2 full

of oil. See Service; Lubrication.

Air Fans and Motor

— Check belt and pulley

alignment. Refer to Condenser Air Fan Adjustment

as required.

Cooling

— To start unit, turn on main power

supply. See Crankcase Heater above. Set thermostat

to COOL, AUTO, and desired temperature. Wait

approximately 5 minutes for compressor to start.

See Time Guard® Circuit. Check cooling effect

at air supply grilles, fan speeds, refrigerant sight-

glass eonditions and operation of all controls and

safety devices.

Accessory Head Pressure Control

— A head

pressure-actuated piston operator, connected to a

damper, regulates airflow thru the eondenser. At

170 F psig diseharge pressure, damper starts to

open. Damper is fully open (horizontal position) at

250 psig.

Pressure Switches

(high and low) cut out at

settings shown in Table 1.

Time Guard® Circuit

provides a delay before

starting compressor after shutdown. At start-up,

timer delays compressor for 12 seconds after ther

mostat closes. On compressor shutdown, timer

recycles for 5-1/2 minutes. During this period,

compressor cannot restart. On 38JB024, timers are

set for a 12-second delay between start-up of

compressor no. 1 and compressor no. 2.

Winter Start

— Timer overrides low-pressure

switch for 2-1/2 minutes. During start-up at low

ambient conditions, this permits system suction

pressure to reach normal operating level. On a sus

tained low-pressure condition, the timer circuit

shuts down until low-pressure switch resets.

Capacity Control

— Two-step thermostat assem

bly cycles each of 2 compressors on 38JB024. On

38JB016, first stage of thermostat cycles com

pressor; second stage of the thermostat can be used

to operate a field-supplied liquid line solenoid for

2-stage operation. Compressor capacity control

unloader responds to suction pressure changes.

C

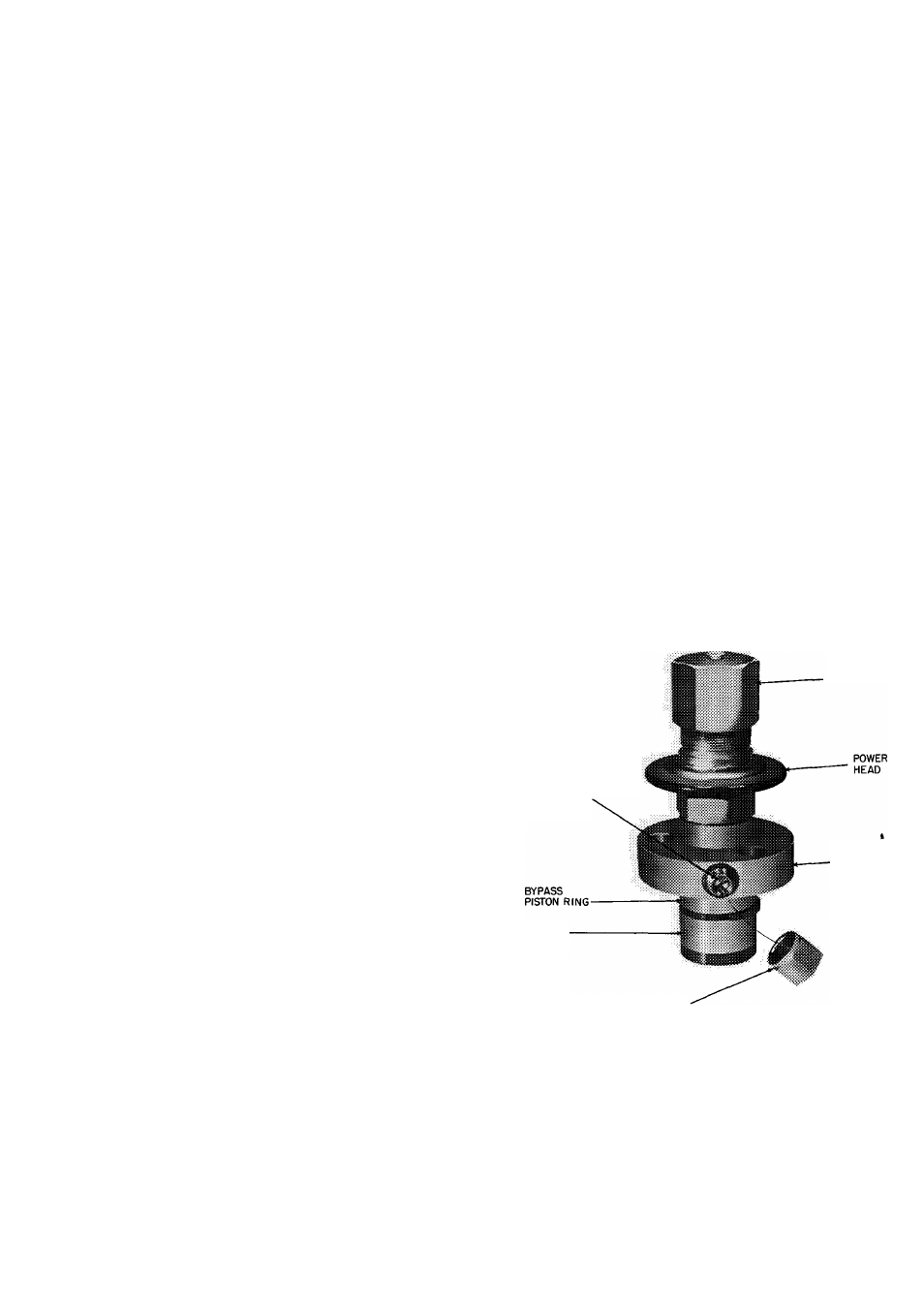

Compressor Capacity Control Unloader

(Fig. 7)

is suction-pressure actuated and controls 2 cylin

ders. Unloader is faetory set to unload at 60 psig

and load at 75 psig but may be field adjusted as

follows;

CONTROL

SET POINT

ADJUSTMENT

NUT

PRESSURE

DIFFERENTIAL

ADJUSTMENT

SCREW

VALVE BODY

BYPASS

PISTON

DIFFERENTIAL SCREW'

SEALING CAP

(CAP MUST BE REPLACED

TO PREVENT REFRIGERANT LEAKAGE)

Fig. 7 — Compressor Capacity Control

Unloader

CONTROL SET POINT (cylinder load point) is

adjustable from 0 to 85 psig. To adjust, turn control

set point adjustment clockwise to its bottom stop.

In this position, load point is 85 psig. Turn adjust

ment counterclockwise to desired load point.