Troubleshooting procedure, Troubleshooting sequence chart – Carrier 31MC User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

. TROUBLESHOOTING PROCEDURE

The following troubleshooting procedure has

been designed to speed the serviceman’s work and

f ,

ensure that any malfunction in the electronic air

"

cleaner is quickly detected and properly repaired.

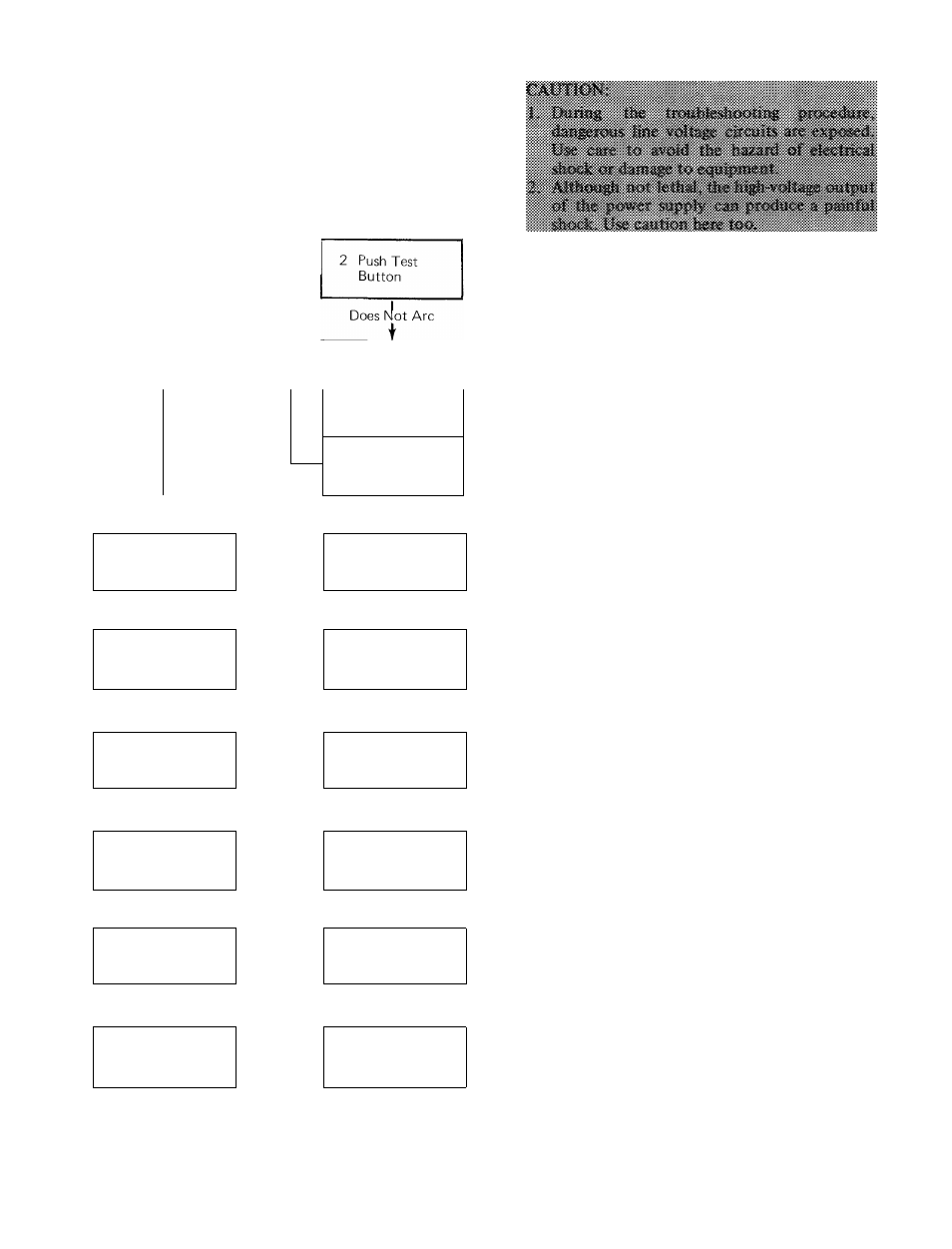

1 Blower on,

Energize EAC

Troubleshooting Sequence Chart

—Light Orp»>-

Unit

Arcs

Check Surge

Resistor

Test Button

Ligh

Off

EAC Operating

Properly

3 Push Test

Button

Unit

Arcs

Check Light

Circuit

I

Does Not Arc

t

4 Remove Cells,

Replace Door

Light

On

Check Ceils,

Contact Tray.

Surge Resistor

Light Off

t

5 Push

Test Button

___,Unit ^

Arcs

Check Light,

Light Circuit and

Cells

1

Does Not Arc

t

6. Check Line

Voltage

Incorrect

Voltage

Check Voltage

Source and

Wiring

Line Voltage Correct

t

7 Disconnect Surge

Resistor, Energize

Power Supply

— Light On-^

Replace

Surge Resistor

1

Light Off

t

8 Check Output of

Power Supply

__ Low or

No Output

Replace

Power Supply

9 Defective Light

Circuit in

Power Supply

Troubleshooting the electronic air cleaner can

be accomplished with only a few tools.

•

Screwdrivers ^ long shank, plastic or rubber

handles; 2 required for some arc checks.

• Jumper cord.

• Voltmeter with 25 kv DC probe.

• Grounding wire.

Most of the steps can be performed by observ

ing the indicator light in the ON-OFF switch. This

light is powered from the high-voltage circuit on

the high-voltage transformer and is on whenever

the high-voltage transformer is working properly.

This procedure is outlined in the Trouble

shooting Sequence Chart. A complete description

is provided on the following pages.

This troubleshooting procedure description is

divided into 2 sections;

1. Diagnostic Tests — The numbered steps cor

respond to the numbered steps on the Trouble

shooting Sequence Chart. Follow this sequence

of tests to locate the cause of a failure within

the air cleaner.

2. Component checks explain how to locate a

faulty component within an assembly, or how

to prove a component good or bad.

Diagnostic Tests

STEP 1

- ENERGIZE ELECTRONIC AIR

CLEANER

a. Be sure electronic cells and prefilter screens are

clean, dry and properly installed in cabinet.

b. Energize electronic air cleaner.

—

Put switch at “On” position.

—

Energize blower.

c. Check on indicator light operation.

—

If light is off, failure is in the electronic air

cleaner — go to Step 3.

—

If light is on — go to Step 2.

STEP 2 - PUSH TEST BUTTON - INDICATOR

LIGHT ON

Test Button Fig. 2, item 6, on the cleaner

access door, provides a simple easy-to-use method

of checking for correct high voltage in electronic

cell. When pushed, it shorts from insulated high-

voltage components to ground. From the sound of

the resulting arc, serviceman may determine

whether or not high voltage is supplied to elec

tronic cell.