Service problem analysis – Carrier 31MC User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

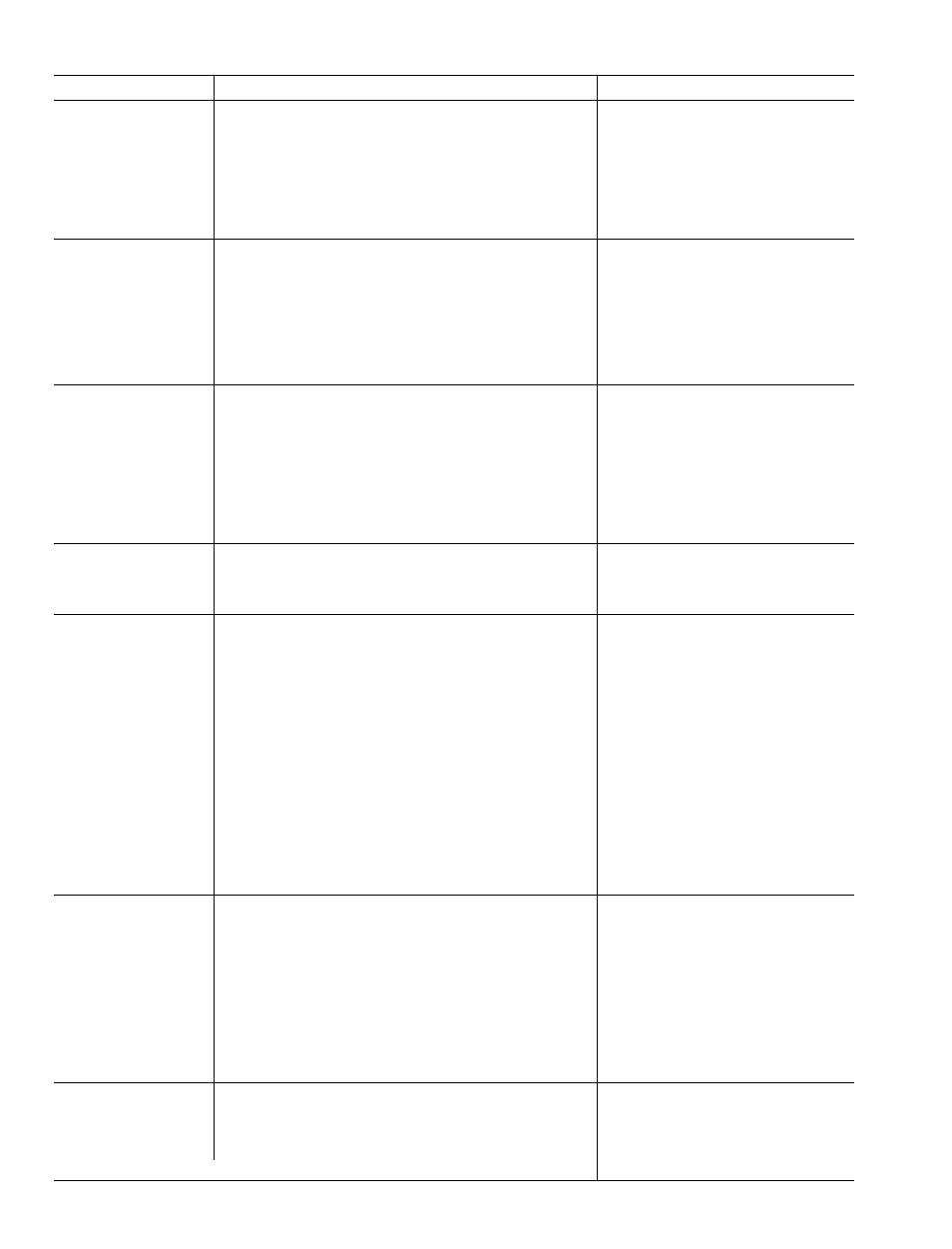

SERVICE PROBLEM ANALYSIS

COMPLAINT

POSSIBLE CAUSES

SOLUTION

Indicator Light Off

Shorted cells

See Troubleshooting Procedure.

Shorted top guide

Defective light

Defective power supply

i

Defective push button

Energize blower.

Blower not operating

Cells wet either due to high humidity or from being

washed

Cells will dry.

Arc Test Button

Shorted cells

See Troubleshooting Procedure.

Produces No Snapping

Shorted top guide

Noise

Defective push button

Defective surge resistor

Defective power supply

System blower not operational

Humidifier upstream

Cells loaded

Energize blower.

Unit Snaps or Arcs

Line voltage too high

Adjust line voltage.

Continuously

Cells need cleaning

Clean cells.

Broken ionizer wire

Replace wire.

Broken contact spring in top guide of power door

Replace spring.

Broken insulator in cell

Replace insulator.

Broken insulator in power door or contact tray

Replace insulator.

Foreign material lodged between plates or in ionizer

Remove object.

Bent plates or media grille for media EAC

Straighten.

Broken or deformed arc test button assembly

Replace or repair.

Humming Noise

Improper wiring connections

Check wiring.

Loose ionizer wires

Replace or repair.

Excessively dirty ionizer or collector

Clean as per Maintenance

Instructions, Owner's Manual

Air Cleaner Doesn't

Lack of power to cells due to improper alignment of

Adjust alignment or replace spring.

Clean Dirt

contact spring on power door to cells in top guide

Defective interlock plug or receptacle

Replace.

Air volume too great

Reduce air volume to design cfm.

Leaks in ductwork on downstream side of air cleaner

Seal.

Dirty air not being delivered to air cleaner

Insufficient air — check return air

grilles

for

obstruction

by

furniture,

drapes, etc.,and remove, check blower

for proper air flow.

Damaged or improperly placed dirt collecting pad

Replace or reposition as per Mainten-

(media-type only)

ance Instructions, Owner's Manual.

Uneven air distribution across face of unit which may

be indicated by uneven loading pattern of dirt in

Install turning vanes or air baffles

collector section of air cleaning cells

The entering air side of collector stage should be evenly

oi

if--*

mwim

sir 5^

covered with dirt. In the case of the 020 sized units, each

cell should have an even loading pattern.

Radio or T.V.

Accumulation of foreign particles lodged in ionizer

Remove.

Interference

section

Unit improperly grounded

Provide good ground to unit.

Ground line of power supply not properly grounded

Correct same.

Loose ionizer wires

Replace.

Loosely connected components, or loose connections

Tighten.

Defective power pack

Replace.

Dents in collector section of ionizer section

Straighten.

Damaged dirt collecting pad (media-type only)

Clean or replace.

Improperly installed dirt collecting pad (media-type

only)

Reposition.

White Dust on

Occasionally a "white dust" might be noticed in bed-

Only air taken thru return grilles is

Furnishings

rooms or newly furnished rooms. This is mainly com

posed of lint which because of its weight, settles before

it reaches your unit. This is not mixed with airborne

dirt. It has no staining or soiling properties and will

cleaned.

j lessen as the excess lint works out of fabrics.

f