Ozone, Service – Carrier 31MC User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

OZONE

The odor of ozone may be noticeable during

operation of an electronic air cleaner. A somewhat

higher ozone generation rate during the first week

or 2 of operation may be caused by sharp edges on

some of the new high-voltage parts. Normal use

dulls these sharp edges in a short time.

The odor of ozone is detectable by an average

person at levels as low as 0.003 to 0.010 parts per

million (ppm). The concentration of ozone pro

duced in a home by an electronic air cleaner ranges

from 0.006 to 0.015 ppm. Average concentrations

of ozone in the air of major cities range from 0.020

to 0.040 ppm and even higher. This is well above

the level produced by an electronic air cleaner.

SERVICE

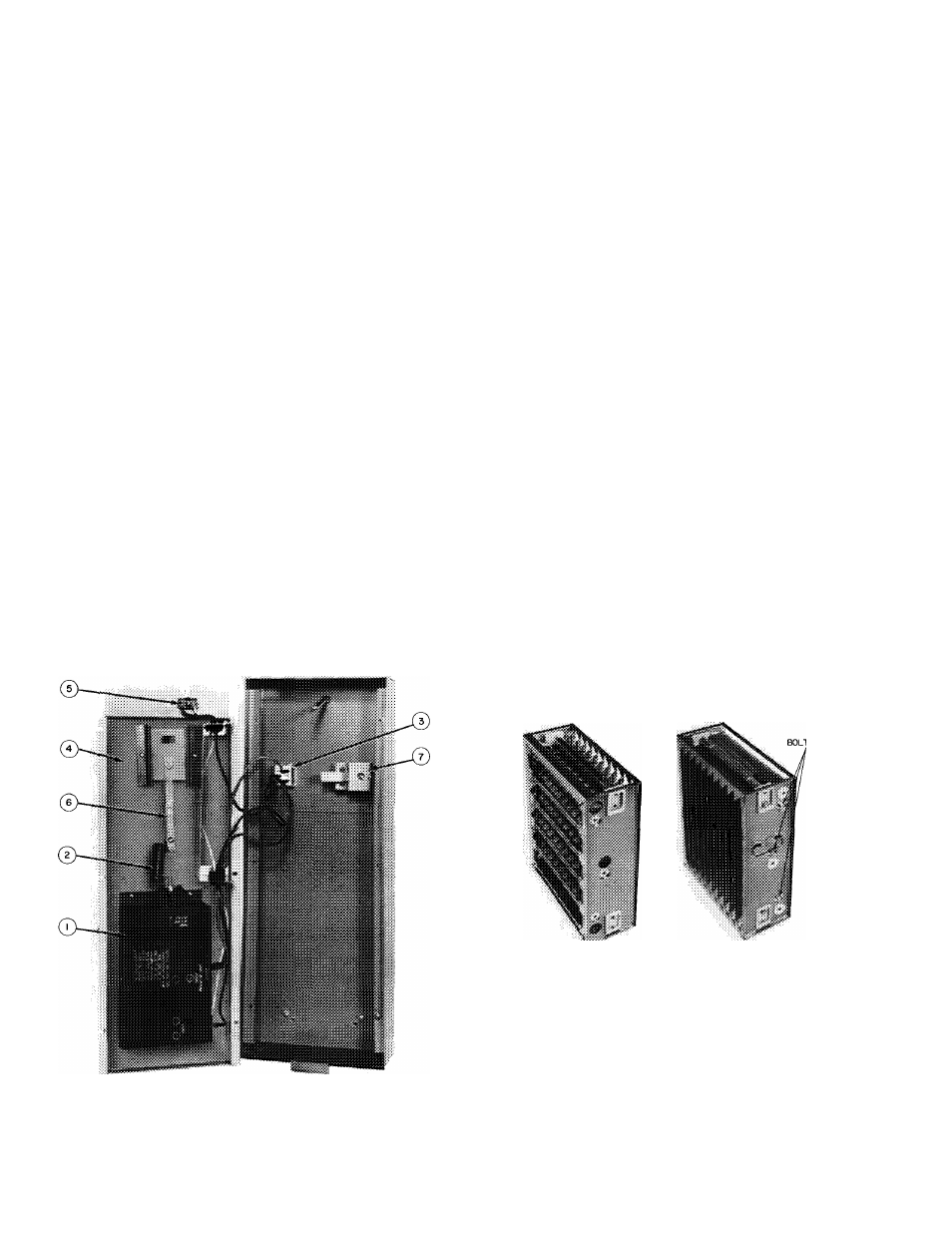

Cabinet Assembly,

Fig. 2, consists of a power door

item 4, which is attached to the cabinet, item 1, by

means of a fastener knob, item 5. Inside the

cabinet are the prefilter, item 3, and the cell, item

2, both of which can be easily slid out of cabinet

for cleaning and service.

Power Door,

Fig. 13, retains all the air cleaning

components inside the cabinet and also contains

the power supply, item 1, which produces high

voltage for the cells. The power door also contains

the surge resistor, item 2, test button, item 7, and

the indicator light and ON-OFF switch, item 3. To

service these components, remove 6 screws from

the ground plate, item 4, on the door and separate

ground plate from door.

1 — Power Supply

2 — Surge Resistor

3 — Indicator Light and

ON-OFF Switch

4

-

5

-

6

-

7

-

Ground Plate

Receptacle

Bus Bar

Test Button

INDICATOR LIGHT AND ON-OFF SWITCH are

both in one unit. Replace complete assembly when

necessary.

1. Disassemble power door. See Power Door.

2. Disconnect wires. Mark wires for reassembly.

3. Compress springs holding light/switch assembly

in door.

4. Pull assembly from front of door.

POWER SUPPLY

1. Disassemble power door. See Power Door.

2. Remove surge resistor connection at the power

supply.

3. Remove 4 sheet metal screws holding the power

supply to the plate.

SURGE RESISTOR is riveted to the bus bar, item

6. The bus bar and surge resistor assembly must be

replaced if the surge resistor is defective.

1. Disassemble power door. See Power Door.

2. Disconnect surge resistor at power supply.

3. Remove screws holding the bus bar.

Cell

— Plate-type and media-type. Fig. 14. The cell

contains the ionizer wires, the ionizer ground plate.

Fig. 15, item 1, and the charged and grounded

collector plate assembly, item 3, of the plate-type

cell.

The plate-type and media-type cleaners are the

same electrically. Physically, however, while the

media-type cell has the same type of ionizer as the

plate-type, a fiber glass pad between a charged grid

and a grounded grid replaces the charged and

grounded collector plate assembly.

Fig. 13 — Power Door

31 MM Media Type

31MP Plate Type

Fig. 14 — Electronic Air Cleaner Cell

DISASSEMBLING THE PLATE-TYPE CELL -

Refer to Fig. 15.

1. Remove 4 sheet metal screws, item 8, holding

the ionizer ground plate, item 1, to the cell

structure, item 2.

2. Lift off the ionizer ground plate.

3. Remove 3 bolts from each end panel. See Fig.

14.