Carrier 28QX User Manual

Page 17

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

#

Any field installed run of horizontal tubing in

the collector loop must be pitched downward a

minimum of 1/4-in. per foot. A pitch greater than

1/4-in./ft, such as 3/8-in./ft or 1/2-in./ft, is accept

able and better than 1/4-in./ft. This pitch require

ment is critical to the installation because failure to

incorporate this requirement will result in system

failure. A l/4-in./ft pitch (min.) and specified

tubing sizes allow positive liquid drainage.

The size of tubing to be used in the “collector

supply” leg of the loop is specified by Carrier.

Both “collector supply” and “collector return”

legs must be insulated.

Add a field procured and installed component

to the “collector supply” leg of the loop — an

ASME approved pressure relief device with a 50

psig set point (not required on plain water system).

Install in a T-joint in the conditioned space side of

the “collector supply” leg. The device should not

project into the supply leg pipe (see detail A of

Fig. 20).

wa,TER

OUT N

2SQX

SUPPt-Y

SUPPLY

■'I

TERMIMATE

8£L0W

LOWEST

WATE3R LEVEL

RETUSN

, , , ,

JU

|! ¡[WATERin-

, j

eXPAiiSlON

TANK

STORAOE

SUPPLY ■

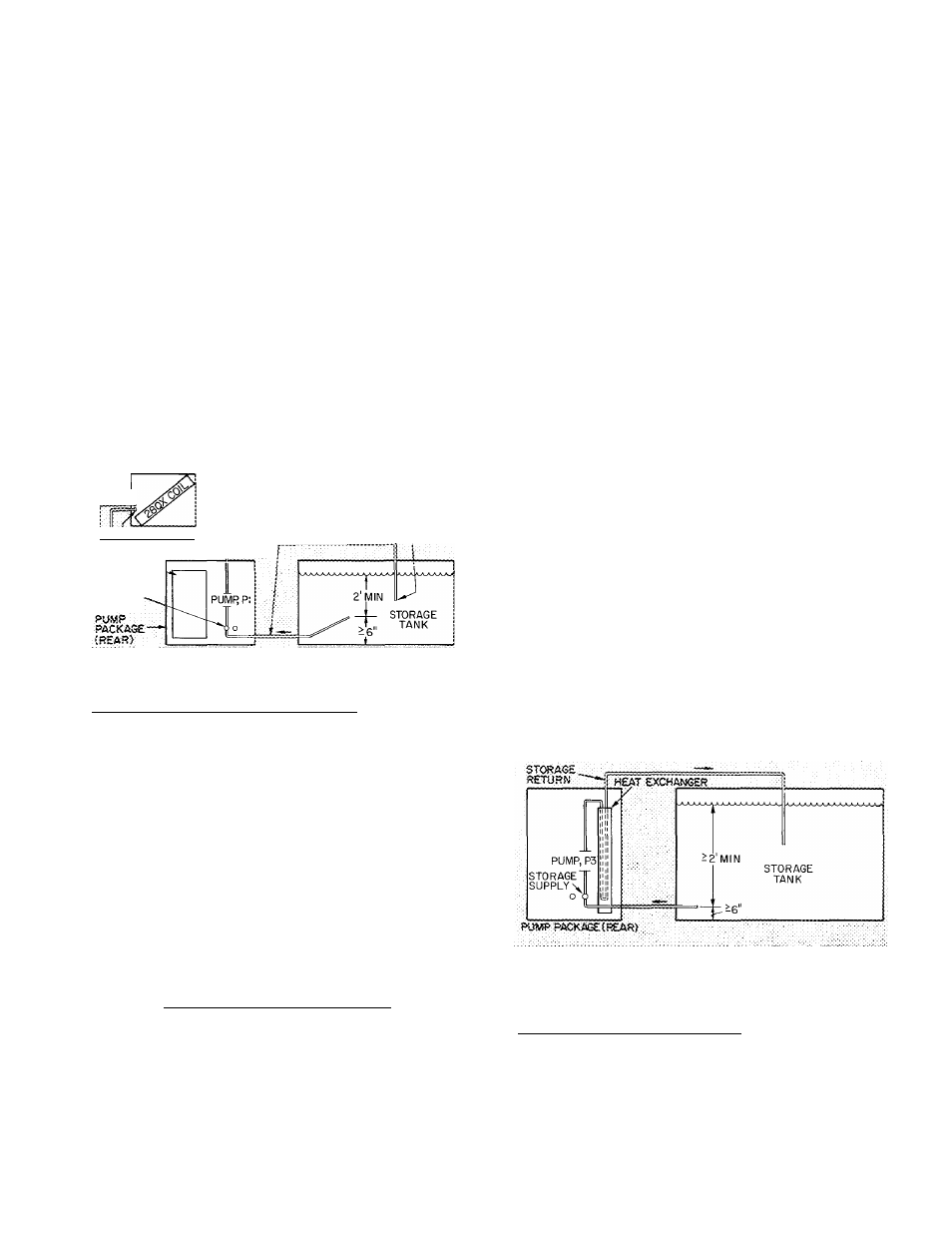

Fig. 21 — Tri-X Coil Piping Loop on Glycol System

28QX (Tri-X) Coil Loop (Fig. 21) — The loop

begins in the storage tank with a pipe at the

bottom of the tank. This pipe exits the tank

bottom and goes to the rear of the pump package

to the left-hand stub labeled “storage supply.” The

loop continues thru a pump and out of the pump

package thru the “28QX supply” stub. The loop

continues to the 28QX coil where it enters at the

“water-in” stub. After traveling thru the coil, the

loop exits at the “water-out” stub of the coil and

returns thru the top or bottom of the storage tank.

(This loop must terminate below the lowest water

level.)

The pipe size and allowable lengths of this loop

are listed below.

ALLOWABLE PIPE LENGTHS

Pipe O.D. (in.) Maximum Equivalent Length (ft)

7/8

1

1

-

1/8

60

120

240

The pipe length listed is for the entire loop length.

A value of 5 equivalent ft should be used for the

pipe inside the pump package. There is no mount

ing height restriction for the 28QX coil since it

operates in a closed loop system. There are,

however, other restrictions.

a. The termination points of the loop (in storage

tank) must always be below the lowest water

level in the storage tank for the loop to be a

closed system.

b. The beginning point for the pipe that enters the

“storage supply” stub on the pump package

must always be at least 2 ft below the lowest

water level in the storage tank but not less then

6 in. from bottom of tank.

c. It is recommended that the 28QX coil be the

highest part of the loop. This is accomplished

by routing the supply and return pipes below

the coil height level. The reason for having the

28QX coil at the highest point is to make the

air bleed valve in the coil effective. If it is not

possible to route the return and supply lines

below the coil, an air bleed valve (similar to the

one found on the 28QX coil water header) will

have to be installed at the highest point in the

loop.

d. If the 28QX coil is mounted more then 6 ft

above the water level in the storage tank, a

special fill-up procedure will have to be

followed. Details can be found in the Start-Up

Instructions section. However, this procedure

will require a booster pump and booster pump

inlet fitting added to the 28QX supply line

between the pump package and 28QX coil. It

will therefore be necessary to add the booster

pump fitting when installing the 28QX supply

pipe. Refer to the Start-Up Instructions for

details concerning the type of fitting to be

used.

Fig. 22 — Heat Exchanger Piping Loop

on Glycol System

Heat Exchanger Loop (Fig. 22) — This loop begins

in the storage tank. A pipe leaving the bottom of

the storage tank travels to the rear of the pump

package to the right stub labelled “storage supply.”

The loop continues inside the pump package thru

the pump and heat exchanger and exits the unit at

the “storage return” stub. From here, the loop

returns to the top or bottom of the storage tank

(should be below the lowest water level).

17