Carrier 28QX User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Fig. 7 — Typical Collector Mounting Frame

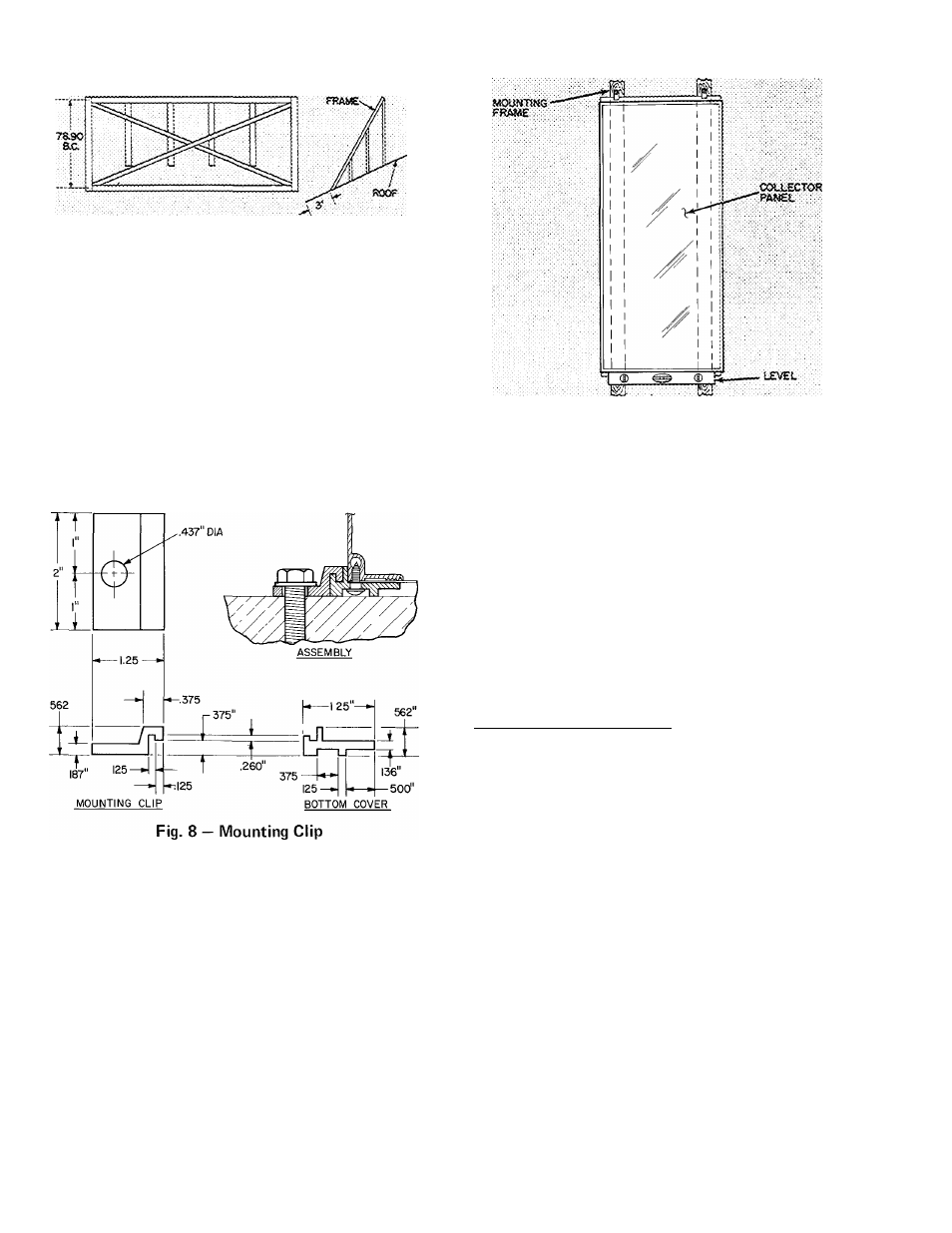

MOUNT THE COLLECTORS on completed frame

or sleepers. Lasten in place with four mounting

clips supplied with each collector. Use 2 clips on

each end of the collector. See Fig. 8. Each clip has

a .437-in. diameter hole to accept a field supplied

mounting screw. Use a level to align the collectors

exactly parallel to the horizontal plane, Fig. 9.

NOTE: There is no fixed top or bottom to a

collector. It can be installed either way,

although it may be preferable to install so

nameplate can be read.

NOTE: Supply and return piping must be sloped

Fig. 9 — Collector Panel Leveling

MAKE PIPING CONNECTIONS - Attach supply

and return piping headers and lines to collectors.

Piping supply line size is specified by Solar CLIC.

Return line is 2-1/8 in. O.D. on all systems. See

Fig. 10. The headers can be completely pre

fabricated.

Determine

distance

between

the

collector inlet connections and outlet connections

(35-in. if panels are butted up to each other). Make

headers with regularly spaced T-sections to mate

with the inlet and outlet of the collector array.

Acquire two 3/4-in. MPT to 3/4-in. sweat

copper fittings for each collector. To each fitting,

solder (95-5) a 3/4-in. copper pipe stub of appro

priate length to maintain a minimum vertical

1/4-in. slope/ft of header. It might be necessary to

bend the copper stubs to maintain this vertical

slope. Thread the fittings with copper stub

attached into the collectors and solder the headers

onto the stubs (Fig. 10). Solder the supply and

return lines in place. Install a tee with a pressure

relief valve between the leaving header and 2-1/8

in. return pipe. Use an ASME approved pressure

relief device with a 50 psig set point and a manual

release lever. (See Leak Testing below.)

If it is necessary for return and supply pipes to

penetrate the roof, install a pitch pocket to seal the

opening.

Install the Collector Sensor on an interior collector

panel after headers have been soldered in place.

Sensor location and method of attachment is

described on pg 15.

LEAK TEST THE COLLECTOR ARRAY ^ Using

city or well water with a minimum pressure of 30

psig, leak test the collectors and piping as follows;

;a. Soft solder (50-50) a temporary cap or end of

2-1 /8 in. collector return line.

b. Attach water supply line to collector supply

pipe.

c.

Fill collector array with water using release

lever on pressure relief valve (Fig. 10) to bleed

air from collector system. If relief valve does

not have a manual release lever, temporarily

replace the relief valve with an air bleed valve.

d. Leave water pressure on to system and check

collectors and piping for leaks per local codes.

e.

If leaks occur, drain water from system by

removing water pressure source. Repair leak

and repeat steps b, c, d and e.

f.

Using a tubing cutter, remove temporary cap

from 2-1/8 in. return line. (This liiie will be

filled with water.)

10