Housing maintenance, Structural maintenance, Duct connections – Twin City Heavy Duty Composite Fiber Fans - IM-410 User Manual

Page 6: Optional accessories, Fan operation - safety

6

Twin City IM-410

Check the condition of the shaft to verify it has not

suffered any corrosive attack. Replace the sub-assembly

if needed.

HOUSING MAINTENANCE

The fan housing is assembled from two FRP halves that

are bolted together with stainless steel bolts and the inte-

rior joint is secondary bonded to prevent leakage. Check

the interior surfaces for any evidence of FRP damage and

repair, if possible, or replace if necessary. An optional

Inspection Door and Drain is available.

The inspection door is bolted to the housing with stainless

steel bolts and sealed with a corrosion resistant gasket.

The FRP drain is secondarily bonded to the low point

in the housing to minimize accumulations of liquid. Check

to insure the drain is not clogged and any fluid is dis-

charged appropriately.

STRUCTURAL MAINTENANCE

All structural components or devices used to support or

attach the fan to a structure should be checked at regular

intervals. Vibration isolators, bolts, foundation, etc. are all

subject to failure from corrosion, erosion, and other causes.

Improper mounting can lead to poor operation characteris-

tics or fan fatigue and failure. Check metallic components

for corrosion, cracks, or other signs of stress. Concrete

should be checked to insure the structural integrity of the

foundation.

DUCT CONNECTIONS

The fan support structure is normally not designed to

carry static loads imposed by the weight of ducts, silencers,

stacks, etc. or dynamic loads from wind or seismic events.

Supporting these loads on the fan inlet and discharge can

cause housing distortion and may cause performance prob-

lems due to the relation of fan housing to wheel. Excessive

loads on the fan housing may damage the FRP housing

and render it unfit for service.

Since FRP is used primarily for its corrosion resistance,

it is recommended that stainless steel fasteners be used.

Use a large washer under the head of the bolt and nut to

increase the load bearing area in contact with the FRP. Do

not tighten these fasteners to the point of crushing the FRP

laminate.

Use of flexible connections is recommended for all

installations and especially when the fan is mounted on

vibration isolators.

OPTIONAL ACCESSORIES

1. Shaft Seals – The standard shaft seal is a Teflon

membrane style shaft closure seal that minimizes

leakage around a FRP sleeve that is encapsulated

over a carbon steel shaft. Optional shaft seal is

either a Viton or Teflon lip seal that is installed in

a cast FRP seal housing. The shaft is encased with

a stainless steel shaft sleeve over a steel shaft. Care

must be taken to insure the integrity of the joint

between the shaft sleeve and the wheel backplate.

Other configurations of shaft seals are available for

special applications.

2. Bolt-On Variable Inlet Vanes – Variable inlet vanes

made of FRP are provided as assemblies externally

to the fan in flanged cylinders that are bolted to the

fan inlet. The vanes are used to control volume and

save power in installations where different volumetric

operating conditions are used. Variable inlet vanes

may be provided for operation with powered opera-

tors or for manual operation. Powered operator

instructions and operating manuals will be provided

when included.

3. Inlet Box and Inlet Box Dampers – FRP inlet boxes

may be provided to allow transition from a rectan-

gular duct to the fan inlet. FRP inlet box dampers

may also be provided for volumetric regulation

similar to inlet vanes. FRP inlet dampers are usu-

ally provided as a complete assembly and are

installed with the damper axis parallel to the fan

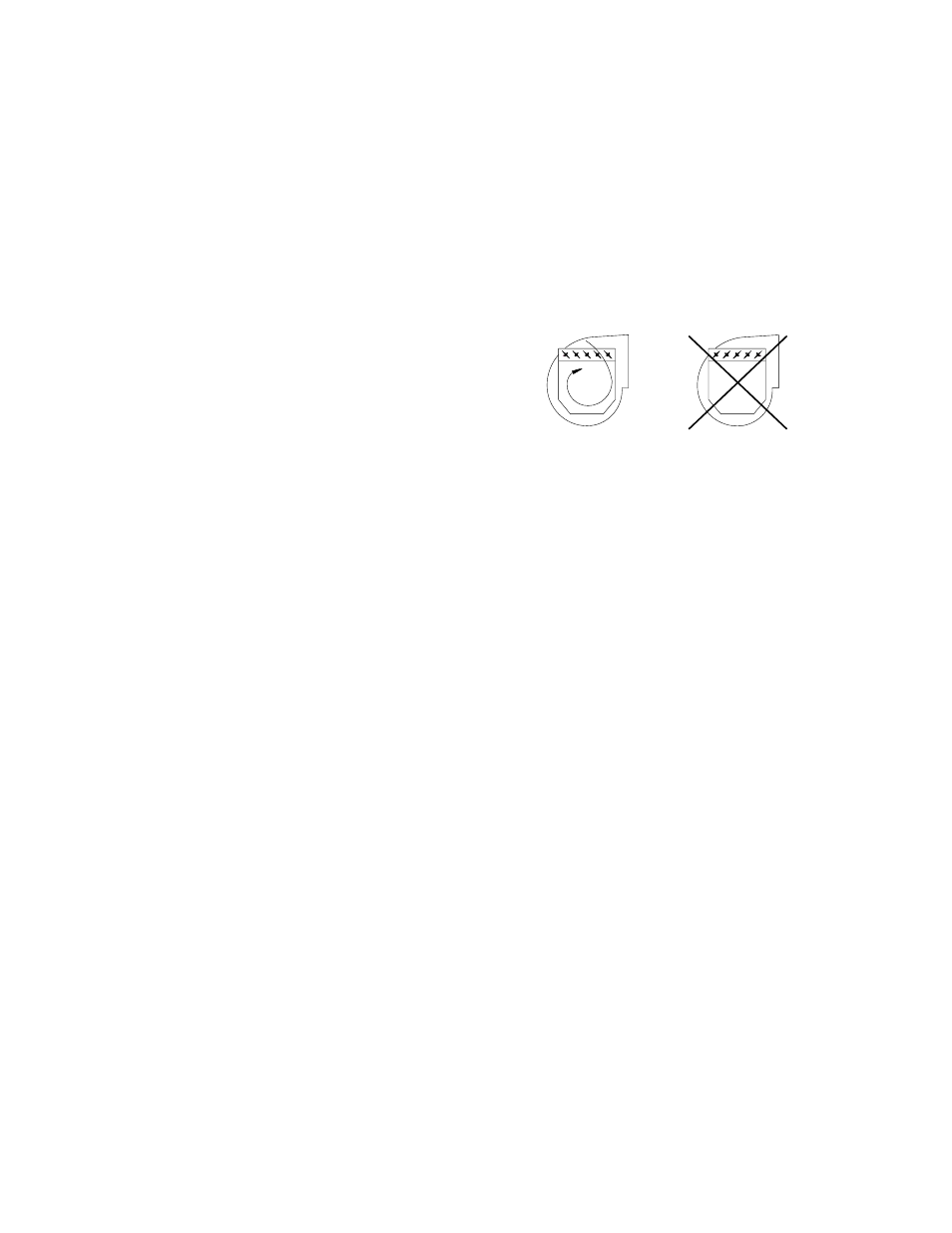

shaft. They must be installed to pre-spin the air in

the direction of fan rotation. See Figure 6 below.

Damage may occur if the fan is operated regularly

with dampers less than 30% open.

4. Outlet Dampers – FRP outlet dampers are usually

provided completely assembled like the inlet damp-

ers. The damper is bolted to the fan discharge

flange for volume control.

5. Oil Circulating System – Usually the following mod-

ifications will have to be made to the split pillow

block bearings if an oil circulating system is used.

a. Four drain holes will be drilled in the bearing,

two on each side of the bearing. Because of

this, the bearing may be drained from either

side. (Drain from both holes on one side of the

bearing.)

b. The bearing will be packed with grease to pre-

vent corrosion until installed and started up.

The drain holes will be plugged with plastic

coversto make sure they are open. NOTE: The

customer MUST REMOVE most of the grease

using solvent and remove the plastic covers

prior to starting the oil circulating system.

c. A wet sump will be added in case of circulat-

ing oil pump failure. Seals will be provided to

minimize oil leakage due to oil splashing.

d. The grease zerk on top of the bearing will be

removed for that hole to be used as the oil

inlet.

6. Anti-Rotation Clutch – Damage will occur if the fan

is operated in the wrong rotation. Run the motor

uncoupled from the fan to establish the proper rota-

tion.

FAN OPERATION - SAFETY

For general safety practices relating to air moving

equipment, see AMCA Publication 410.

Twin City Fan & Blower has many safety accessories

available. These safety devices include (but are not lim-

ited to) belt guards, shaft guards, inlet guards, and

discharge screens. The use, abuse, or non-use of

safety devices is the responsibility of the purchaser.

Facility-related safety conditions include fan accessi-

bility and location.

• How easily can non-service personnel access

the unit?

•

Is the fan in a hazardous duty environment?

•

Was the unit ordered for this duty?

Other concerns must also be addressed.

All fans should be powered through safety switches

which are easily accessible to service personnel and in

close proximity to the fan. Every safety switch should

RIGHT

WRONG

Figure 6. Orientation of Damper Blades