3twin city engineering supplement es-35 – Twin City Protective Coatings Guide - ES-35 User Manual

Page 3

3

Twin City Engineering Supplement ES-35

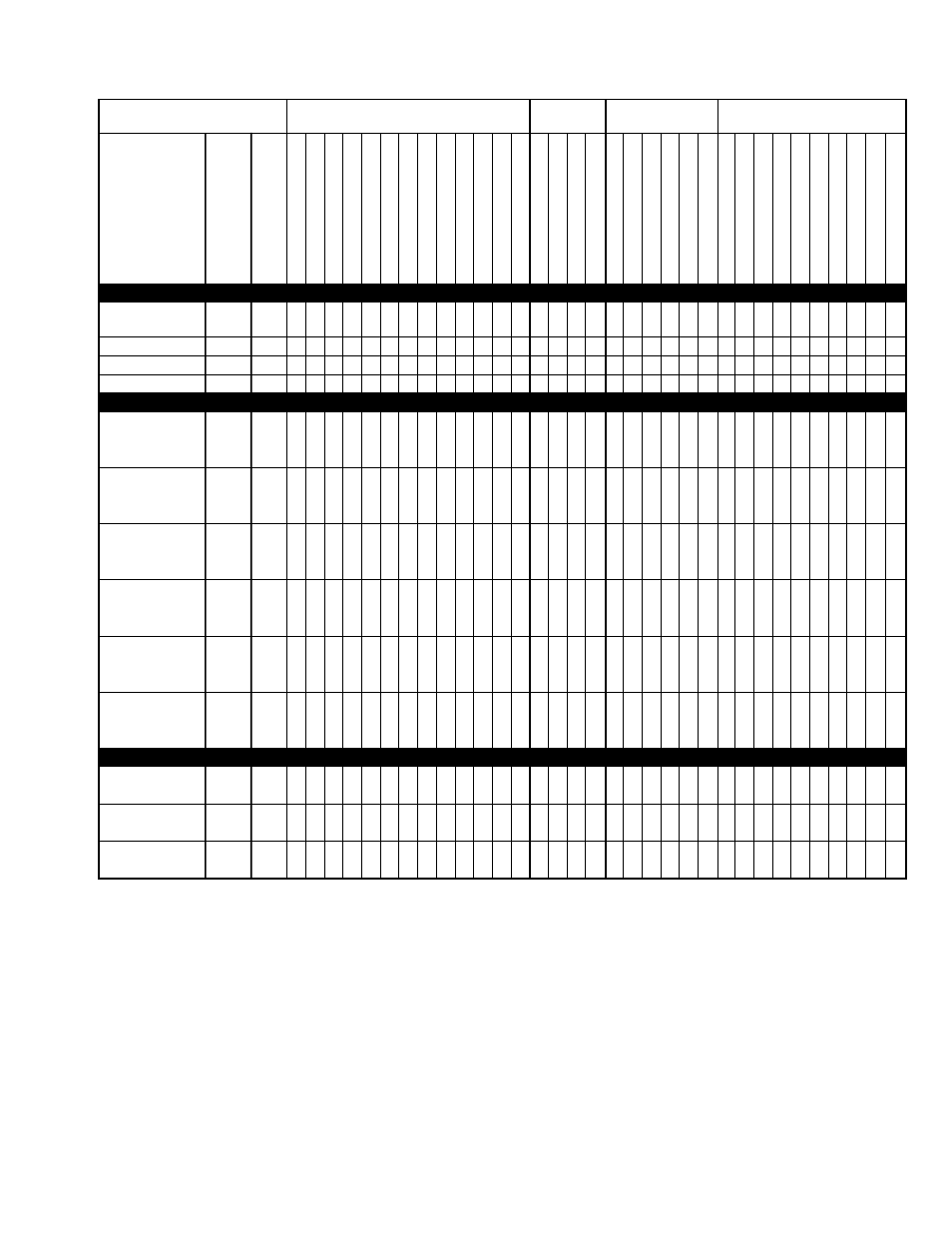

SELECTION INSTRUCTIONS

Coatings with E or G ratings should be selected, if possible, for best results throughout.

E = Satisfactory from 15% to 85% (depending upon coating) of concentration of fumes and for continuous operation. Also suitable for splash or

condensation.

G = Good for up to 5% to 15% of concentration of fumes. Not recommended for applications involving splash or condensation.

F = Fair. Recommended for low (maximum 5%) concentration application. Should not be specified unless detailed application is available.

U = Unsatisfactory and hence not recommended.

X = Sufficient data not available at present. User comments would be appreciated.

* Please refer to page 4 for descriptions.

** Max. operating temperature indicates coating failure, not color change. Chalking or discoloration may below this temperature.

NUMBER

OF

COATS

MAX

OPERATING

TEMP.

(°F)**

COPPER

SULPHATE

FERRIC

CHLORIDE

HYDROGEN

PEROXIDE

POTASSIUM

CYANIDE

POTASSIUM

HYDROXIDE

POTASSIUM

DICHROMATE

SODIUM

BICARBONATE

SODIUM

CHLORIDE

SODIUM

DICHROMATE

SOIDUM

HYDROXIDE

SODIUM

HYPOCHLORITE

ZINC

CHLORIDE

ZINC

SULPHATE

BENZENE

BUTAINE

GASOLINE

XYLOL/TOLUOL

STEAM

VAPOR

-

SAT.

AMONIA

GAS

-

DRY

AMMONIA

-

WET

CHLORINE

-

DRY

HYDROGEN

SULPHIDE

SULPHUR

DIOXIDE

ABRASION

MOISTURE

SALT

SPRAY

ACETONE

ALCOHOL

FORMALDEHYDE

METHYL

ETHYL

KETONE

MINEARAL

OILS

POLYVINYL

ACETATE

TRI

CHLORETHYLENE

ASPHALTUM

(Not Recom-

mended

For Fans)

G X X F U F F G U E E F E G X F

E E E U F G E E U E G E E E X F

E E E U F F E E F E E E E E X E

E E E F E G U E G E E E E G X G

G G X G G X U E E U F F F E X X

G F X G G X U E E U F G U E X U

X X X X U U G E E E E E E X X U

G X F G G X U E E G G G G E E G

E E X E G G G E E U E X U U X U

U U U G G G G E G G G G G F U G

E G X G E U G E E G E E U G X U

E U U E E E G E E E E E E E G E

E X X E E U G E E E E E G X X U

CORROSIVE REAGENT

ACID SALTS, NEUTRAL SALTS,

HYDRO-

GASES & FUMES

MISCELLANEOUS

ALKALINE SALTS, ALKALIES, ETC.

CARBONS

CORROSION

RESISTANT:

• METALS

• PAINTS

• COATINGS

METALS

LOW CARBON

—

600

STEEL

ALUMINUM

—

250

304 S.S.

—

1000

316 S.S.

—

1000

PAINTS — TCF&B STANDARD SURFACE PREPARATION

2

200

VINYL (PVC)

2

150

ZINC

2

350

EPOXY

2

200

POLYESTER

SYNTHETIC

2

200

RESIN

AIR-DRIED

4

150

PHENOLIC

COATINGS — SURFACE PREPARATION INCLUDES STEELBLASTING

EPOXY

PHENOLIC

2

350

BAKED EPOXY

PHENOLIC

400

BAKED EPOXY

400

U U U X G G X G G E X X F E X G E

U U E U U E E G X U G U E E E E E

E U E E E E E G X E F U E E X E E

E F E E E E E E X E G G E E X E X

G G F X E G E E E F F X G U X U G

G G F X E F E E X G F X X F X G U

E E X X U E X E E G U X U E X E G

G G G X G F G E X G F X G G X G G

E E G X E X E E X G G E E U E E U

E E U G F G E E U U U G G G G G U

E E U X U G E E X G U X E E X E E

E E U E U E E E F U U G E E E E E

E E G X G E E E X G G X E E X E G

2 to 4

4 to 5