Top Flite TOPA1025 User Manual

Page 5

5

ASSEMBLE THE WING

❏

1. If necessary, use a covering iron with a covering

sock to go over the wing and aileron to remove any

wrinkles. The best method to remove the wrinkles is

to glide the iron over the covering until the wrinkles

disappear, then go over the area again, pushing down

on the iron to bond the covering to the wood. If the

wrinkles don’t disappear, the balsa in that area might

be fl exing inward. If this is happening, don’t press down.

Simply let the heat of the iron shrink the covering. If

the wrinkles momentarily disappear, then immediately

reappear, the iron may be too hot, thus causing air

bubbles. Lower the temperature of the iron or use a

sharp #11 blade or T-pin to puncture several holes in the

covering, then reheat. The suggested iron temperature

is around 360 degrees F.

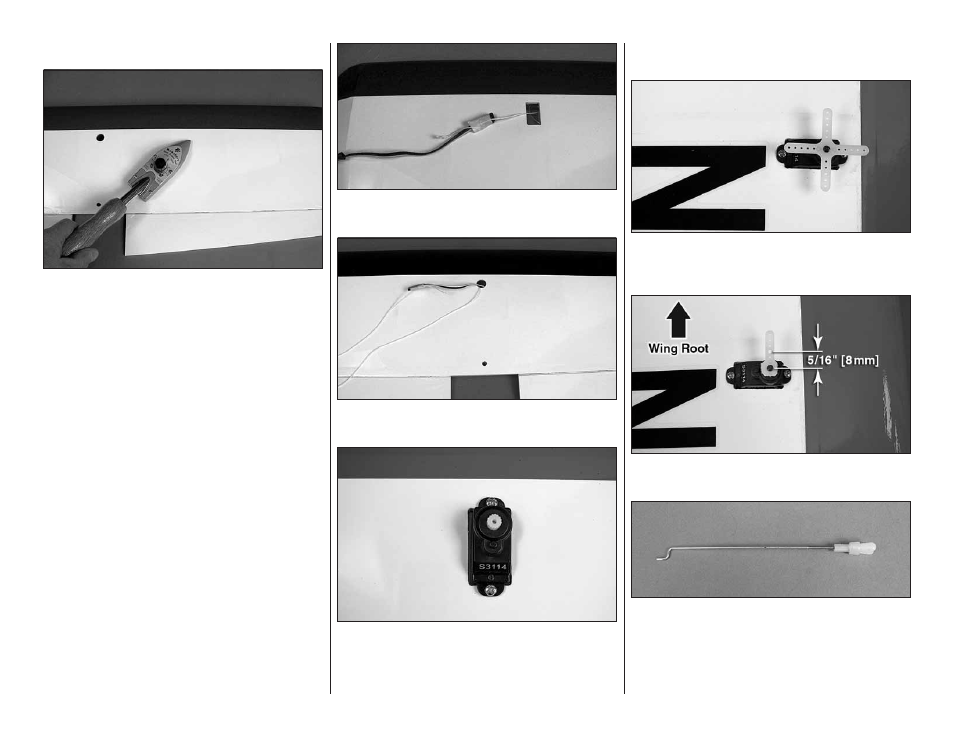

MOUNT THE AILERON SERVOS

❏

❏

1. Connect a 6" [152mm] servo extension to

one of the aileron servos. Secure the extension to

the servo lead with a piece of heat shrink or electrical

tape (not included).

❏

❏

2. Carefully pull the string from the aileron servo

opening and tie it to the end of the servo extension.

❏

❏

3. Pull the aileron servo lead through the wing

and out of the opening on the top of the wing.

❏

❏

4. Use a #55 drill bit or small T-pin to drill pilot

holes for the servo mounting screws. Mount the aileron

in the wing with two #2 x 1/4" [2 x 6mm] sheet metal

screws. Remove the screws and servo. Apply a drop

of thin CA in each screw hole. After the CA has cured,

reinstall the aileron servo and screws.

❏

❏

5. Install a servo arm on the aileron servo so

that it is perpendicular to the centerline of the servo.

Remove the three unused arms.

❏

❏

6. Use a 1/16" [1.6mm] drill bit to enlarge the

hole 5/16" [8mm] from the center of the servo arm.

❏

❏

7. Thread a nylon clevis 20 turns onto the 2-56 x

4-7/16" [110mm] metal pushrod. Slide a silicone clevis

keeper over the nylon clevis.

❏

❏

8. Connect the nylon clevis in the enlarged hole

of the servo arm.