Installation of xi2 concrete systems – Tie Down Xi2 "IBC 2009 90 mph Exposure C Foundation System" User Manual

Page 3

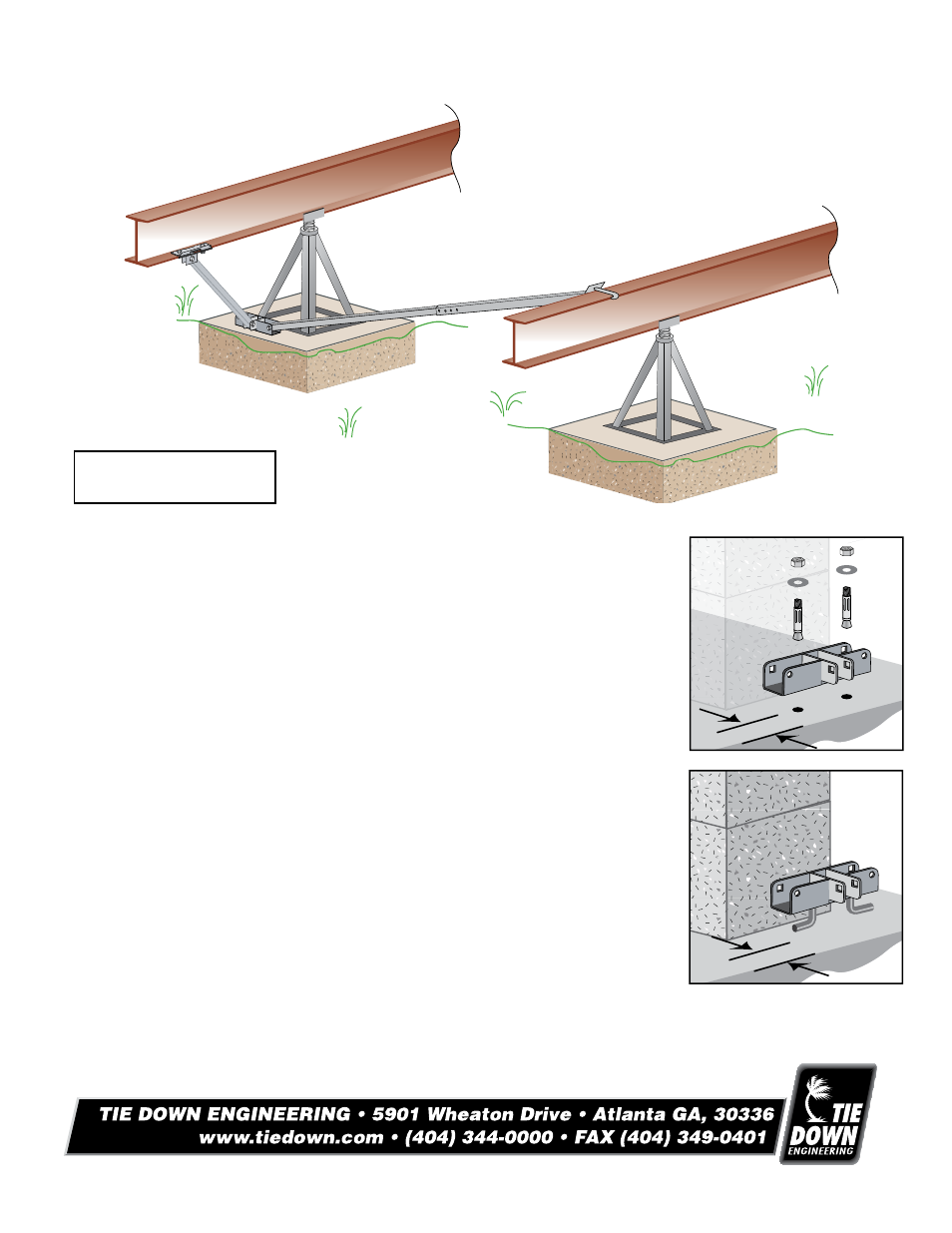

1. Identify the number of systems to be used on the home using the chart provided.

2. Identify the location where the systems will be installed.

3. Build pier according to State, Local or unit manufacturers guidelines.

4A. Drill two 3/8”x 3” deep holes in the concrete using holes in galvanized bracket

as a guide. Attach bracket to concrete pad using 3/8”x3-1/2” wedge anchors

provided. Place nut & washer on anchor, leave enough room for 1 to 2 threads

showing on top of bolt. Using a hammer, tap the wedge bolts into hole

through bracket, leaving nut & washer flush with bracket. Using a 9/16” socket

wrench, tighten wedge/anchor bolt, securing bracket to the concrete.

4B. For wet set: align bracket and submerge legs completely in concrete. Bottom

of the bracket should rest on the surface.

5. Attach the end of the smaller tube to the bracket mounted on the pad, using the

grade 5, 1/2” x 2-1/2” bolt/nut provided.

6. Attach the flag end of the larger tube to the opposite I-beam using the “J” bolt

over the top of the I-beam with the nut & washer provided. (Figure 1 next page)

7. Install a minimum of four (#12 x 1” tek screws) self-tapping screws into the

holes provided in the lateral strut so that the two tubes are connected together

8. Install frame bracket clamps on I-beam on the inside of block/pier.

9. Insert strut in frame bracket clamp and attach with nut & bolt. Attach opposite

end to concrete bracket.

10. Pull the frame bracket clamp with fastened strut outward to remove any slack.

11. Tighten all nuts and bolts on system.

Lateral

Longitudinal

Beam Clamp

Bracket

J-Bolt

Nut & Washer

1-1/2" Tube

Lateral Struts

1-3/4" Tube

4 - #12 x 1"

Tek Screws

I-Beam

Xi2 Concrete System

Installation of Xi2 Concrete Systems

Minimum Distance

from edge: 1-1/2”

Page 3 of 4