Apply here, Apply here stainless steel wear sleeve spindle – Tie Down Turbo Lube User Manual

Page 7

7

Turbo Lube Hub (Front Fill) Installation/Replacement Instructions

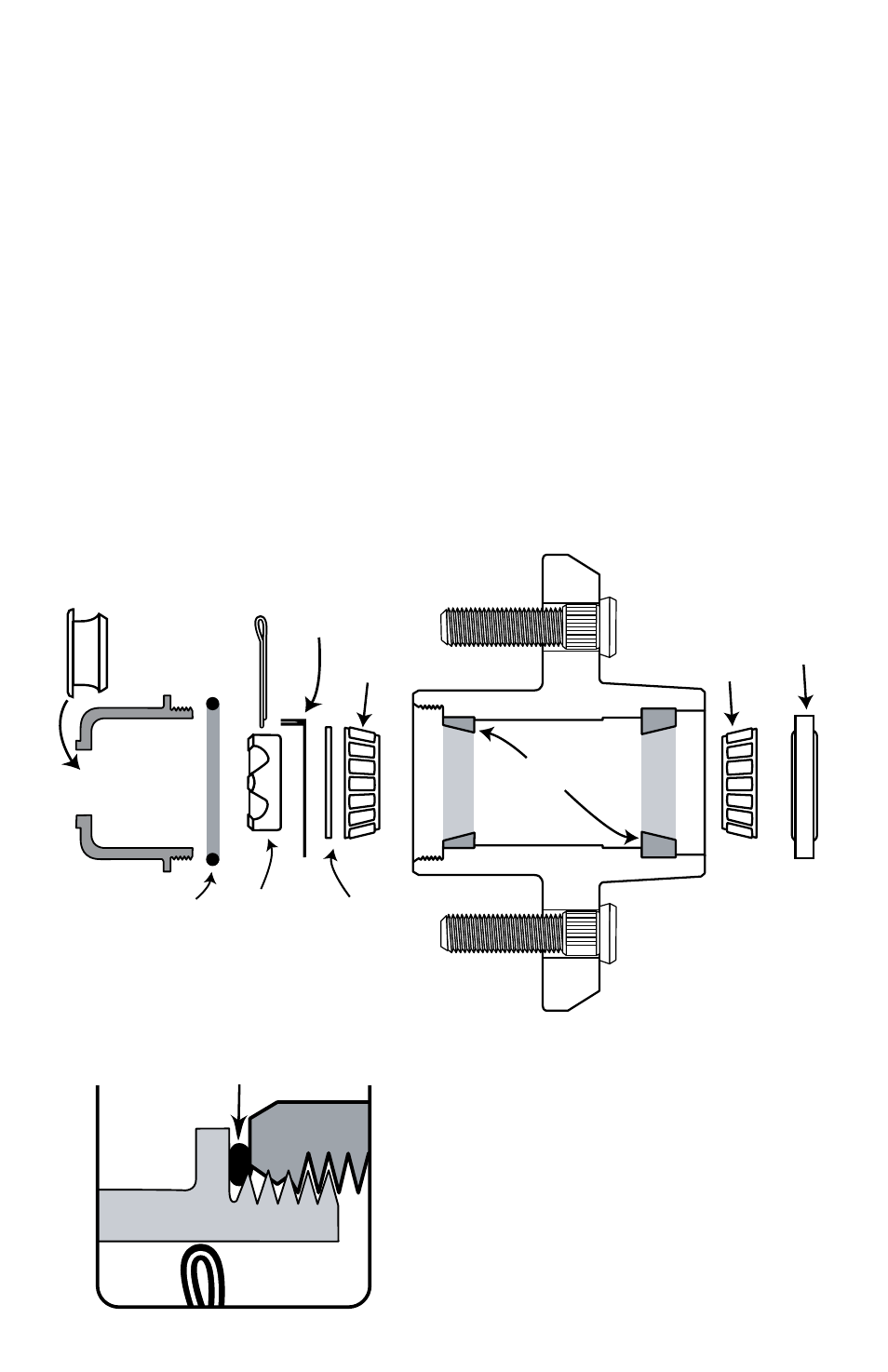

Fill Level - Bottom of file hole

Seal

Bearing

Bearing

Cups

Spindle

Nut

Cotter

Pin*

Oil Plug

Turbo

Lube

Cap

O-Ring

Flange

Lock*

Thrust

Washer

* Hub kit contains either cotter

pin or flange lock

O-Ring

Oil Cap, View

current oil level

Oil filling plug, no

need to remove cap

Triple lip, spring

loaded oil seal

Completely sealed oil

reservoir chamber permits

maximum lubrication

Apply Here

Apply Here

Stainless Steel

Wear Sleeve

Spindle

1. Remove wheel from hub.

2. Remove hub dust cap, cotter key or flange washer, spindle nut and thrust washer.

3. Remove old hub from spindle.

4. Assemble new hub. Set bearings as shown, if not already pre assembled.

5. Wipe spindle clean, check for any noticeable wear or rust.

6. Place a thin coating of oil or grease on spindle surface.

7. Mount Turbo Lube Hub.

8. Tighten the spindle nut with a 1/2 inch torque wrench to approximately 40 ft. lbs.

Turn wheel in both directions to confirm wheel turns freely.

9. Turn back spindle nut 1/6 turn maximum to the nearest cotter key or flange

washer locking position. Wheel should turn smoothly with no end play or wobble.

10. Install oil cap, turn clockwise, snug by hand and then turn 1/4 additional turn.

Do not over tighten. See back diagram.

Hand tighten cap until snug. Use wrench to

turn an addition 1/4 turn. Check to make

sure the O-ring is seated properly. Be careful

not to over tighten. Check oil level, fill if

necessary. Tighten oil plug cap.

Fill Level - Bottom of file hole

Seal

Bearing

Bearing

Cups

Spindle

Nut

Cotter

Pin*

Oil Plug

Turbo

Lube

Cap

O-Ring

Flange

Lock*

Thrust

Washer

* Hub kit contains either cotter

pin or flange lock

O-Ring

Oil Cap, View

current oil level

Oil filling plug, no

need to remove cap

Triple lip, spring

loaded oil seal

Completely sealed oil

reservoir chamber permits

maximum lubrication

Apply Here

Apply Here

Stainless Steel

Wear Sleeve

Spindle