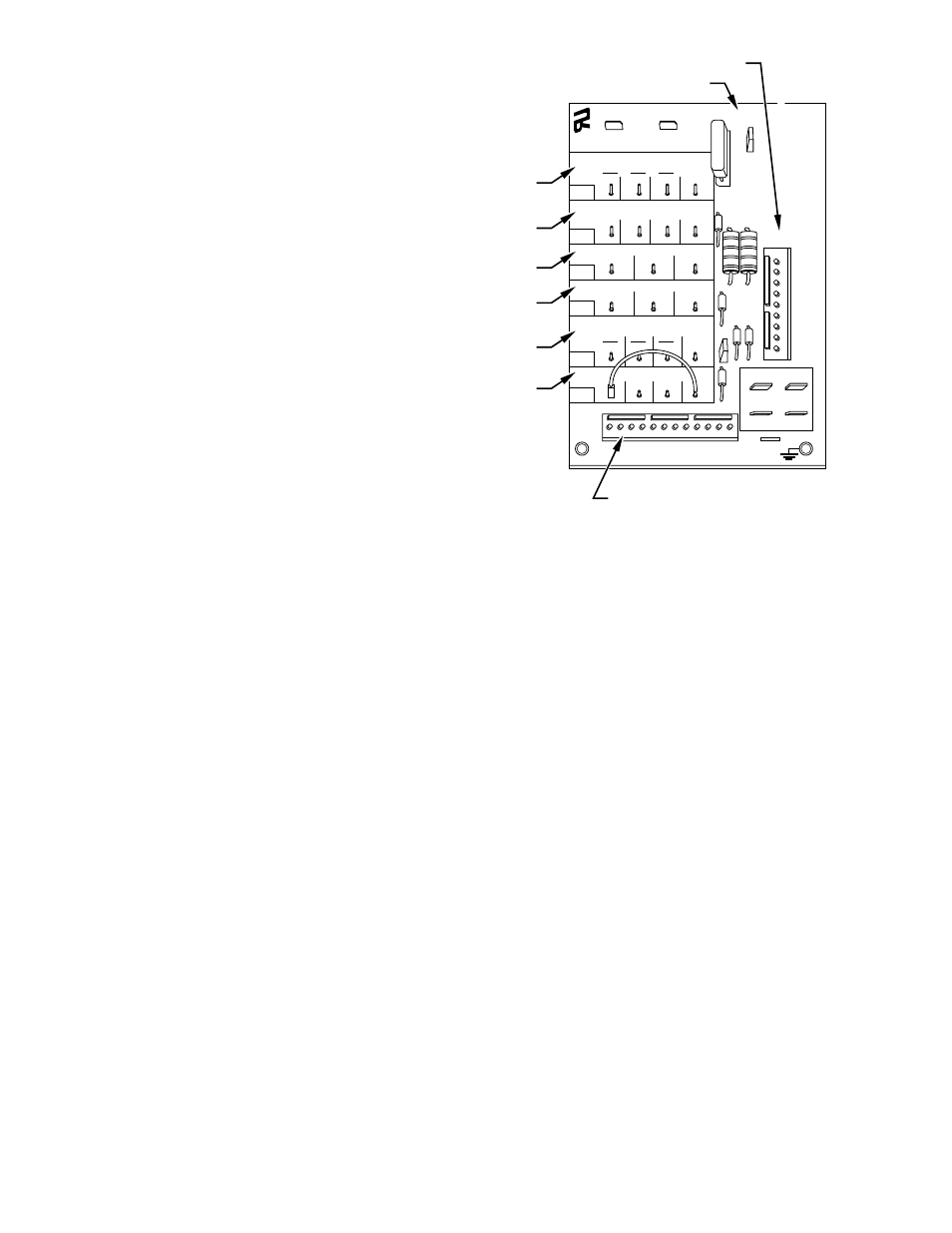

Fig. 8—detail of spp printed-circuit board – Carrier 50JZ 024-060 User Manual

Page 5

b. COOLING MODE

(1.) If indoor temperature is above temperature set point and

humidity is below humidity set point, thermostat closes

circuits R to G, R to Y/Y2 and R to O—The unit delivers

single speed cooling airflow.

c. COOLING MODE-DEHUMIDIFICATION

(1.) If indoor temperature is above temperature set point and

humidity is above humidity set point, thermostat or Ther-

midistat™ closes circuits R to G, R to Y/Y2, R to O and

humidistat or Thermidistat™ opens R to DH—The unit

delivers airflow which is approximately 80 percent of the

nominal cooling airflow to increase the latent capacity of

the system.

d. COOLING MODE-SUPER DEHUMIDIFY OPERATION

(SEE QUICK REFERENCE GUIDE)

NOTE: The indoor control used, such as a Thermidistat™, must

be capable of providing Super Dehumidify operation mode and

control must be configured as outlined in its installation instruc-

tions. Consult indoor control literature to determine if control is

capable of providing Super Dehumidify inputs and for configura-

tion instruction.

(1.) If the indoor temperature is below the temperature set

point and the humidity is above the humidity set point, the

Thermidistat™ closes circuit R to O, opens circuits R to

DH and R to G, and closes circuit R to Y/Y2. If circuit R

to G is closed (24-v.), the motor will deliver airflow at the

full cooling or cooling plus dehumidify mode requested

value. If circuit R to G is open (0–v.) for Super Dehu-

midify mode, the motor delivers reduced airflow to maxi-

mize the humidity removal of the system while minimizing

over cooling.

e. GAS HEATING MODE

(1.) Thermostat closes circuit R to W/W1—The unit delivers

the selected gas heat airflow. The IGC will control a 45

sec. blower “On” delay and a 45 sec. “Off” delay.

EASY SELECT™—48JZ

NOTE: Either the Carrier Thermidistat™ or Dual Fuel ther-

mostat is required for operation of the dual-fuel (48JZ) units.

Be sure to follow the installation instructions supplied with the

Thermidistat™. Either indoor temperature control must use

an outdoor air sensor to properly control heating operation.

EASY SELECT™ CONFIGURATION TAPS FOR 48JZ

Easy Select™ taps are used by the installer to configure a system.

The ICM motor uses the selected taps to modify its operation to a

pre-programmed table of airflows.

The unit must be configured to operate properly with system

components with which it is installed. To successfully configure a

basic system (see information printed on circuit board label located

next to select pins), move the 6 select wires to the pins which

match the components used (See Fig. 8).

a. GAS HEAT/CFM—SELECT GAS HEAT INPUT SIZE

Factory selected gas heat size should correspond to unit label.

b. AC/HP SIZE—SELECT SYSTEM SIZE INSTALLED

Factory selected air conditioner size should correspond to

capacity of unit installed. Installer should verify air conditioner

size to ensure that airflow delivered falls within proper range

for the size unit installed. This applies to all operational modes.

c. SYSTEM TYPE—SELECT SYSTEM TYPE INSTALLED

Factory selected on 48JZ for HP-EFF.

SELECT OPTIONS

1. HP-COMFORT provides approximately 315 CFM/ton for

higher normal heating air temperature and provides approxi-

mately 350 CFM/ton cooling airflow for good humidity re-

moval

2. HP-EFF (factory selected) Provides equal airflow for heating

and cooling modes to increase overall heat pump efficiency.

Provides approximately 400 CFM/ton.

d. AC/HP CFM ADJUST—SELECT NOMINAL, LOW, OR

HIGH AIRFLOW

The AC/HP CFM Adjust select is factory set to the High-HI

(NOM for 036, 060) tap. The CFM Adjust selections NOM/LO

will regulate airflow supplied for all operational modes, except

non-heat pump heating modes. HI provides 15 percent airflow

over nominal unit size selected and LO provides 10 percent

airflow below nominal unit size selected. Adjust selection

options are provided to adjust airflow supplied to meet indi-

vidual installation needs for such things as noise, comfort, and

humidity removal (See Fig. 8, D as indicated).

e. ON/OFF DELAY—SELECT DESIRED

TIME DELAY PROFILE

Four motor operation delay profiles are provided to customize

and enhance system operation (See Fig. 8, E as indicated).

Selection options are:

(1.) The standard 90 sec off delay (Factory Setting) at 100

percent airflow in cooling or heat pump heating mode. In

gas heating mode, IGC will control a 45 sec “On” delay

and a 45 sec “Off” delay.

(2.) A 30 sec cooling delay with no airflow/ 90 sec off delay at

100 percent airflow profile is used when it is desirable to

allow system coils time to cool-down/heat-up in conjunc-

tion with the airflow in cooling or heat pump heating

mode.

(3.) A no delay option used for servicing unit or when a

thermostat is utilized to perform delay functions. In gas

heating mode IGC will control 45 sec on delay with no

airflow and 45 sec off delay.

Fig. 8—Detail of SPP Printed-Circuit Board

C01039

EASY SELECT

HEATER/MOTOR

GAS HEAT/CFM

090

1250

SEC1

SEC2

J1

AC/HP SIZE

036

030

024

018

AC

HP-COMFORT

HP-EFF

NOM

HI

ENH

LO

SYSTEM TYPE

AC/HP CFM ADJUST

ON/OFF DELAY

CONTINUOUS FAN

MED

HI

YEL

LO

AUX1

HUM1

AUX2

24VAC

GRY

HUM2

YEL

WHT

BLK

ORN

BLU

VIO

060

1100

040

800

0

90

30

90

0

0

N/A

TM

J2

D

H

R

W

1

W

2

Y

1

Y/Y

2

G

O

C

9 PIN CONNECTOR

ICM PRINTED CIRCUIT BOARD

12 PIN CONNECTOR

A

B

C

D

E

F

5