Fitting the sieve sensor, Position – TeeJet LH 865 User Manual

Page 15

LH 865 C

APACITY INDICATOR

– O

PERATORS MANUAL

& F

ITTING INSTRUCTION

LH A

GRO

15

FITTING THE SIEVE SENSOR

POSITION

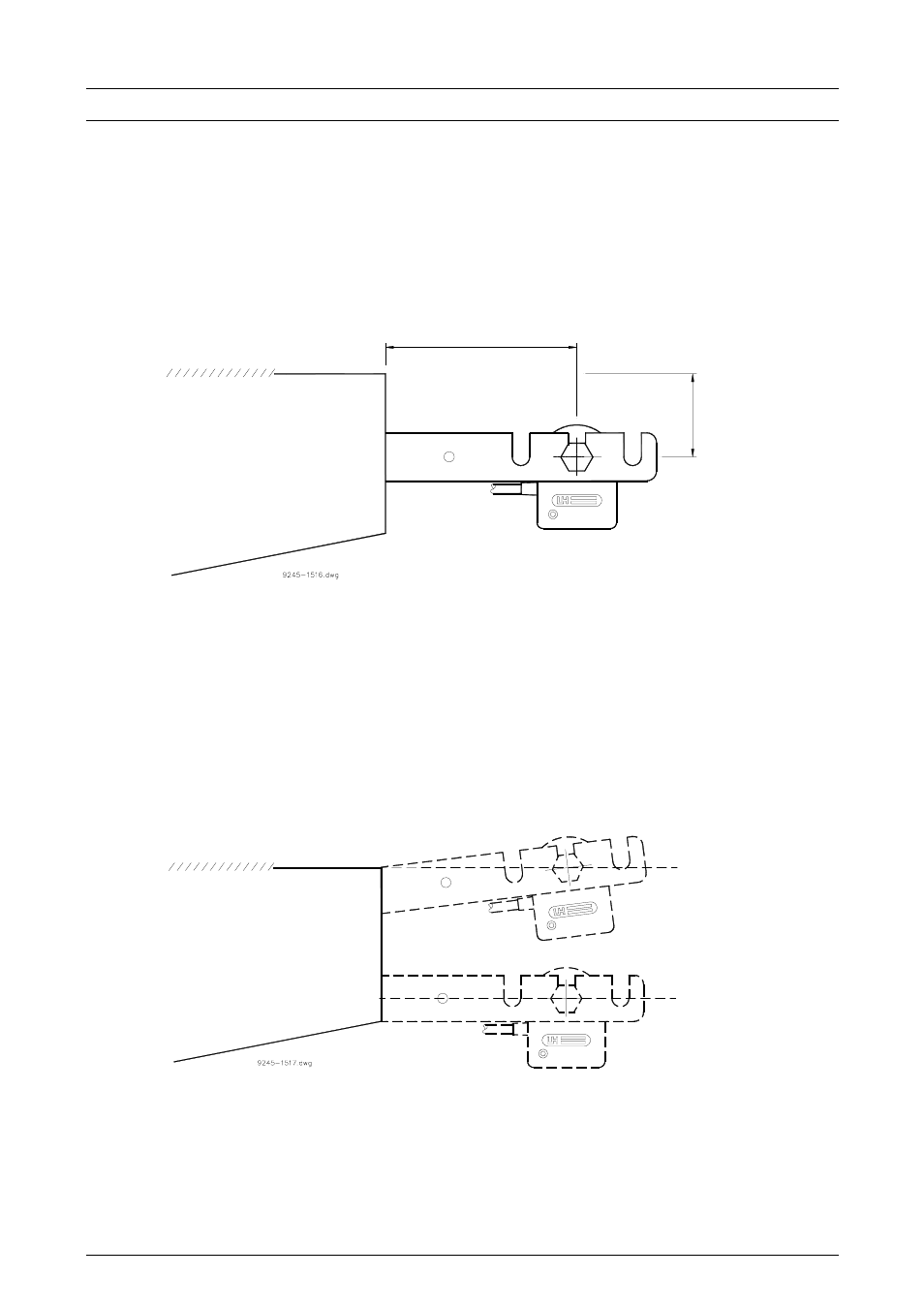

The sieve sensor must be fitted so that it can measure the grain loss behind the

sieves over the whole width of the sieves. The best position for normal grain types

is 120 mm behind the rear edge of the sieves and 50 mm under the sieves

(measured from the centre of the tube).

120 mm

50 m

m

The supplied brackets have three slits, when fitting measure from the middle slit.

This allows the sensor to be moved closer to the sieves when harvesting a crop

where not much air is blown under the sieves, i.e. oil seed rape. If the crop being

harvested needs a lot of air to be blown under the sieves the sensor can be moved

further away.

On some machines it might not be possible to fit the sensor in the recommended

position due to, e.g. the adjustment handle. In such cases it may be necessary to

fit the sensor higher or lower than the height given in the above. The centre of the

sensor must not be higher than the sieves or lower than 100 mm under the sieves.

0 mm

100 mm

Once the correct position has been found the brackets can welded or bolted to the

sieves. The point at which the brackets are attached must be stable so that the

sensor does not shake.