Ower, Peed, Odule prg can – TeeJet MT 600 Piston Injection Pump User Manual

Page 5: Roduct, Ontrol, Witch, Ense, Odule prg can sw txd mag

98-05086

R1

98-05086

R1

5

MAINTENANCE

Midwest Technologies recommends the following maintenance to keep

your system operating at peak efficiency.

F

LUSHING

A

ND

C

LEANING

Always refer to the chemical manufacturer's directions regarding cleaning

and flushing

D

AILY

P

UMP

M

AINTENANCE

Check pump head oil level. Oil level should be visible and never over-

filled above 1/2 of the viewing window

Do not leave chemical in the pump or application lines overnight. The

system should be flushed and cleaned at the end of each day’s operation.

W

EEKLY

P

UMP

M

AINTENANCE

Check the pump carefully for wear each week during frequent operations.

Check for cracking, belt wear, or other signs of material fatigue. If any

signs of deterioration are seen, that may need replaced immediately

(contact your Mid-Tech dealer).

The pump calibration must be checked anytime the pump head is added or

subtracted.

S

EASONAL

P

UMP

M

AINTENANCE

Install ball and seat repair kit (Part# 54-02031) See Figure 5 above

The pump calibration must be checked at the begin of each season of

operation and periodically throughout the year.

8

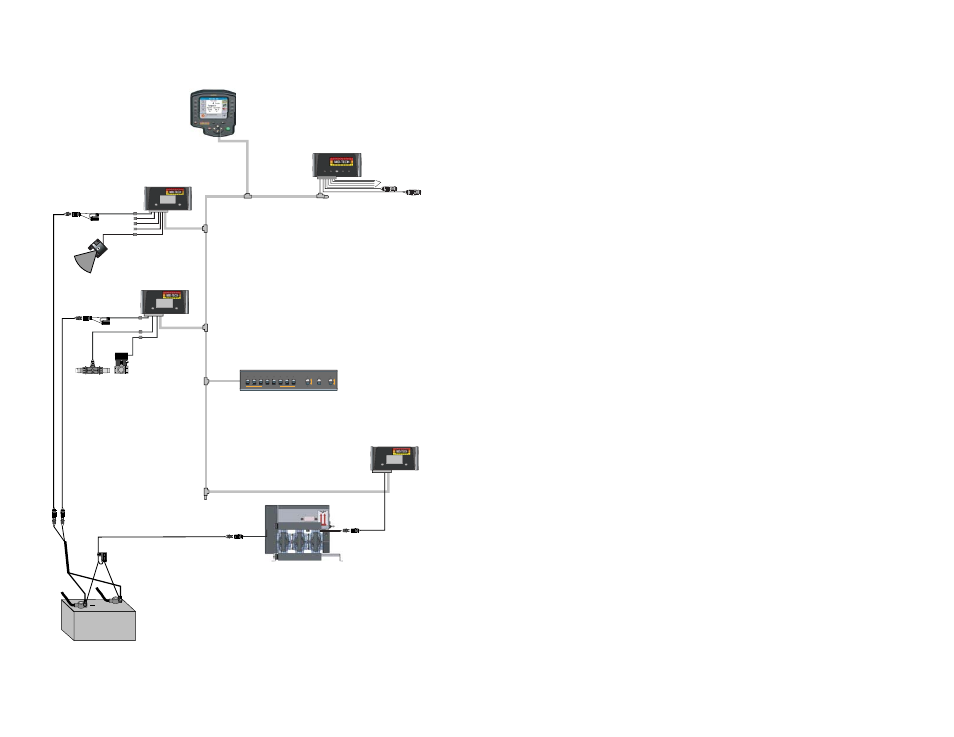

TYPICAL LEGACY SYSTEM WIRING

Ignition

RS-232 Port

CAN Gateway

Speed Sensor

Terminator

Flowmeter

Flow Control Valve

Vehicle Battery

(12 Volts)

White

Black

A

B

P

ower

S

peed

M

odule

PRG

CAN

P

roduct

C

ontrol

M

odule

PRG

CAN

PSM

S

witch

S

ense

M

odule

PRG

CAN

SW

TXD

MAG

Boom Sense 1 - 10 (or 1 - 20)

GSO

Imp. Stat.

SSM

PCM

Terminator

P

roduct

C

ontrol

M

odule

PRG

CAN

PCM

+

A

B

A

B

A

B

Legacy 6000 Controller

A

B

Legacy 6000 Injection

Wiring Diagram

A

B

MT600 Injection Pump

PRODUCT CONTROL

RATE

B

A

OFF

1

2

3

4

5

6

7

8

% RATE

HANDGUN

SLOPE

OFF

+

+

-

-

Product Switchbox