Fine adjustments, Pressure switch adjustment – Sonics 1596 Actuator User Manual

Page 18

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

I N S T R U C T I O N M A N U A L • M O D E L 1 5 9 5 / 1 5 9 6

17

F I N E A D J U S T M E N T S

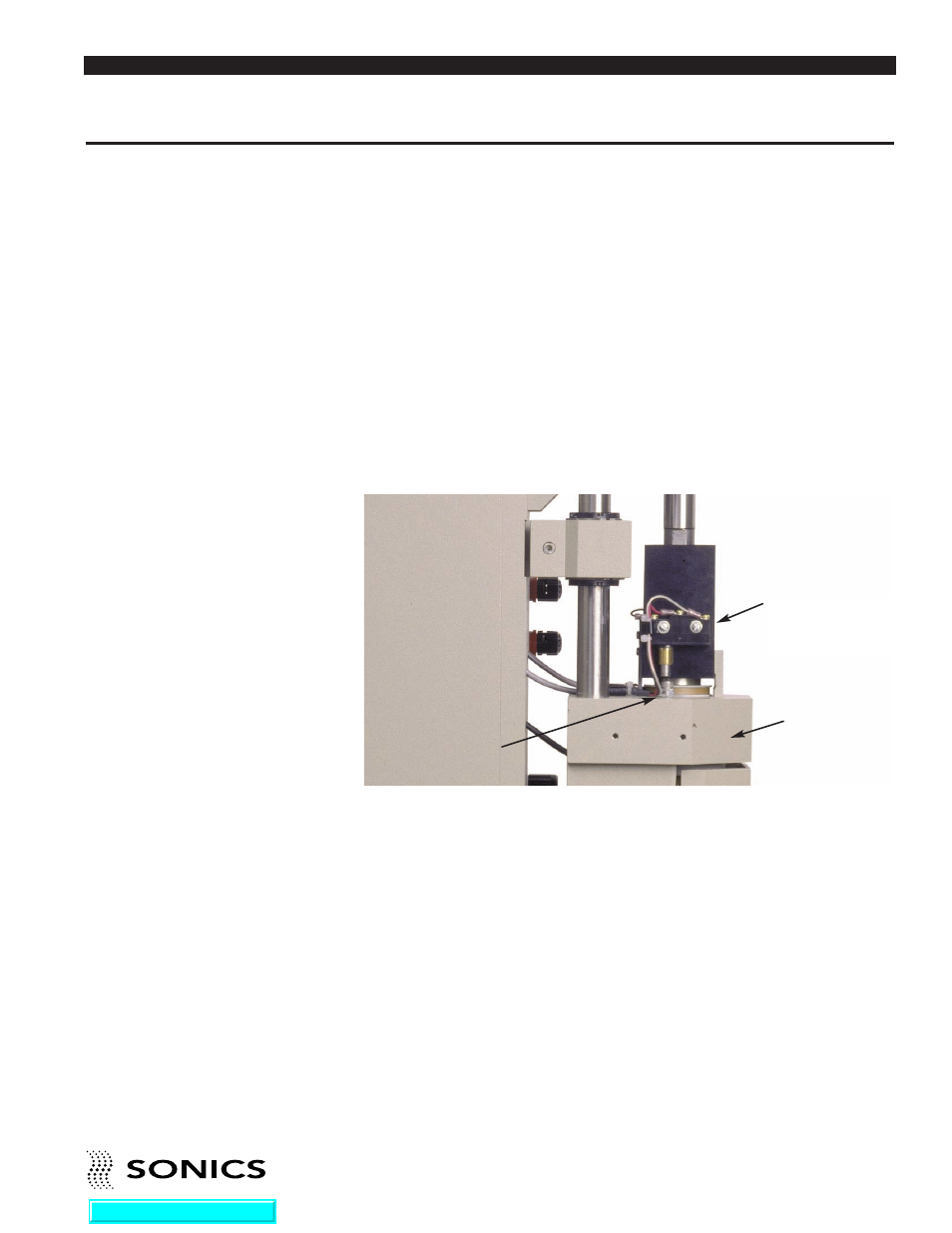

PRESSURE SWITCH ADJUSTMENT

For systems mounted in the normal vertical position with downward travel, no

adjustment should be necessary. The minimum trigger pressure is factory set

to approximately 10-12 psig (69 kPa/.7 bar - 83 kPa/.8 bar).

However, if the minimum trigger pressure requires recalibration or re-

adjustment, observe the following procedure:

1. Maintain air pressure and unplug the power supply from the electrical

source.

2. Remove the four screws holding the five-sided cover.

3. Loosen the jam nut holding the 8-32 cap screw in place.

4. Rotate the cap screw counter-clockwise (up) until the Pressure Switch

closes.

5. Next rotate the cap screw clockwise (down) until the Pressure Switch

opens.

6. Rotate cap screw clockwise (down) 1/4 turn past the Pressure Switch

open position.

7. Tighten the jam nut to lock cap screw in position.

8. Replace the cover and four screws.

9. Plug the power supply into the electrical source.

10. Cycle the welder.

A press actuating in an upward direction should be set to trigger at a minimum

of 14-16 psig (a value which is nominally factory set only if “Sonics” is notified

prior to purchase that the press will be used for vertical welding). Lower

values may affect trigger performance where false triggering may be

observed.

CAP SCREW

TOP OF

CONVERTER

HOUSING

PRESSURE

SWITCH

Go To Top Of Document