Horn and fixture alignment – Sonics 1596 Actuator User Manual

Page 15

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

14

I N S T R U C T I O N M A N U A L • M O D E L 1 5 9 5 / 1 5 9 6

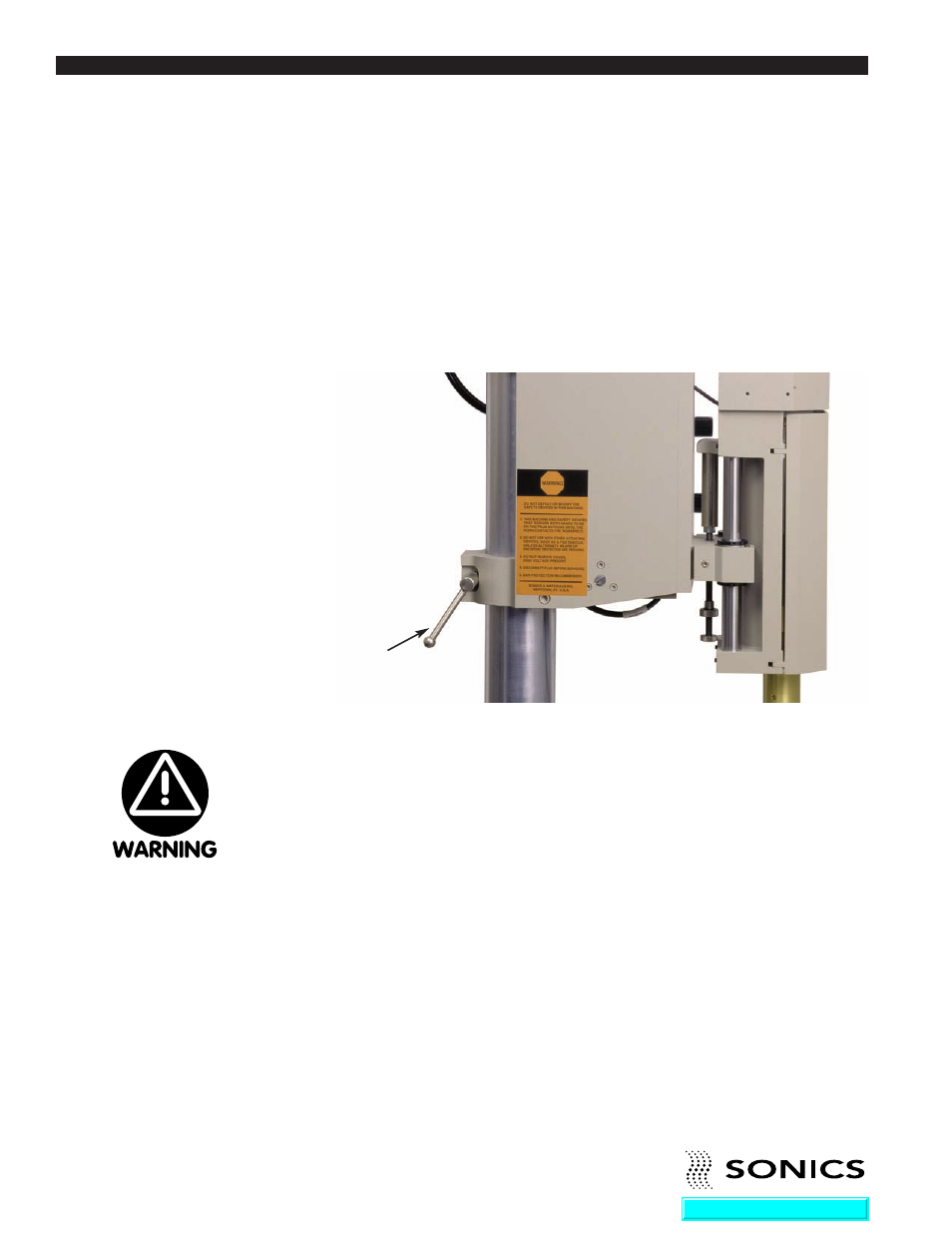

HORN AND FIXTURE ALIGNMENT

For maximum productivity, the clearance between the horn and the part

should be at a minimum. However, adequate clearance should be provided to

enable easy loading and unloading of the part from the holding fixture. The

maximum stroke distance is 4" (optional 6" stroke available). Ensure that the

head is not too close to the limit of its down travel distance. Otherwise, the

horn may not have sufficient distance to travel downwards to achieve a full

depth of weld. Set welding height as described below:

1. Position the holding fixture loosely on the base plate using 3/8-16 screws.

2. Place the part to be welded in the fixture.

3. Set the air pressure to zero by turning the UP PRESSURE regulator knob

fully counterclockwise.

4. To get the head into the position desired, use one or both of the methods

described below to make adjustments as needed:

a. Loosen the two column clamps (counterclockwise) and use the HEAD

POSITION buttons to move the head up or down.The head can also be

manually rotated slightly (from side to side).Once the head is in the

desired position, tighten the column clamps.

b. With the column clamps locked (tightened) in place, the HORN DOWN

Key switch (which activates the air cylinder) can be used to advance the

horn.

5. Loosen the cap screws on the converter housing door and gently rotate the

converter/booster/horn assembly as required to ensure proper horn-to-part

alignment.

When the air pressure

is decreased, the

converter housing can

drop down to its limit,

so be sure to either

support it or remove

anything in its path.

HEAD

ASSEMBLY

COLUMN CLAMPS

Go To Top Of Document