Cleaning and maintenance – OmniSistem OnyxPro 40 User Manual

Page 18

Category _Configuration

PAN_INVERT

0x0600

TILT_INVERT

0x0601

Category _Control

IDENTIFY_DEVICE

0x1000

RESET_DEVICE

0x1001

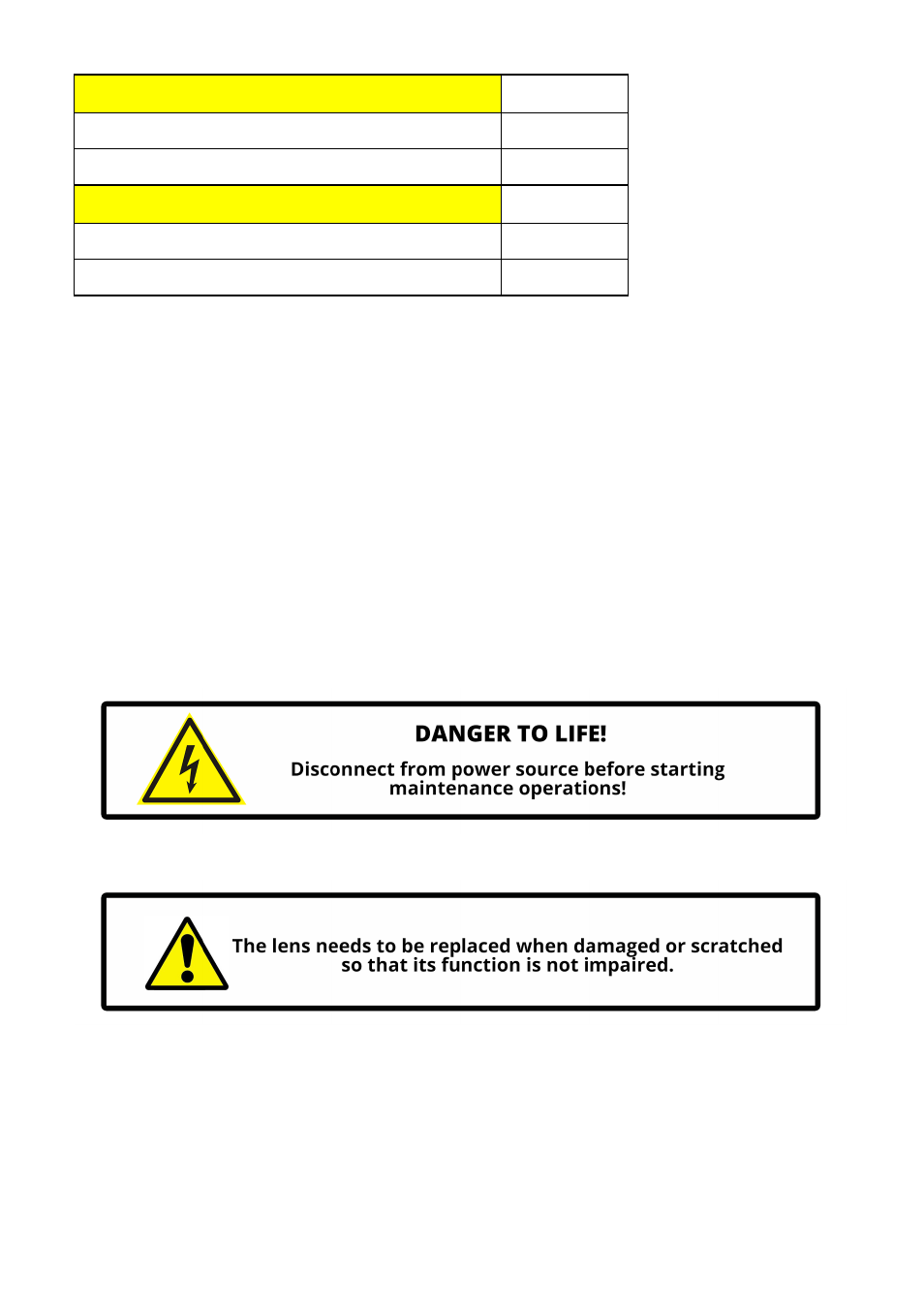

CLEANING AND MAINTENANCE

The operator needs to make sure that safetyrelated and machinetechnical installations are inspected by an

expert after every four years in the course of an acceptance test.

The operator needs to make sure that safetyrelating and machinetechnical installations are inspected by a

skilled person once a year.

The following points must be considered during the inspection:

1) All screws used for installing the devices or parts need to be tightly connected and not corroded.

2) There must not be any deformations on housings, fixations, and installation spots (ceiling, suspension,

trussing).

3) Mechanically moving parts like axles must not show any traces of wearing (e.g. material abrading or

damages) and must not rotate unbalanced.

4) The electric power supply cables must not show any damages, material fatigue (e.g. porous cables), or

sediments. Further instructions depending on the installation spot and usage need to be adhered by a skilled

installer and any safety problems have to be removed.

We recommend a frequent cleaning of the device. Please use a moist, lintfree cloth. Never use alcohol or

solvents!

The objective lens will require weekly cleaning as fog/smoke machine fluid tends to build up residues, reducing

the light output very quickly. The cooling fans should be cleaned monthly.

The interior of the fixture should be cleaned at least annually using a vacuum cleaner or an air jet.

There are no serviceable parts inside the device. Maintenance and service operations are only to be carried out

by authorized dealers.

Replacing the Fuse

Only replace the fuse by a fuse of same type and rating.

18 of 20